Anti-static polybutylene-based packaging film material and preparation method thereof

A polybutene and packaging film technology, applied in the field of materials, can solve the problems of high voltage discharge, weak water vapor barrier, affecting the quality of goods, etc., and achieve the effect of good barrier performance and good antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

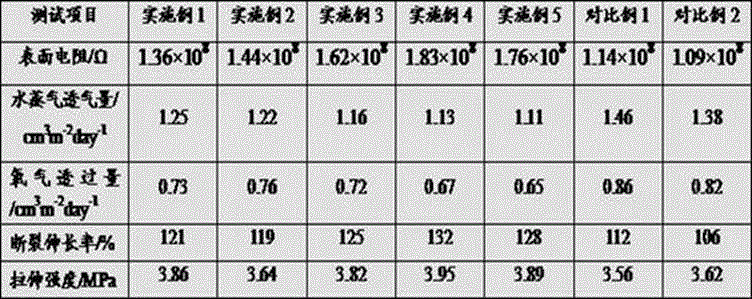

Examples

Embodiment 1

[0021] An antistatic polybutene-based packaging film, prepared from the following components in parts by weight: 32 parts of polybutene, 15 parts of polybutylene succinate, 8 parts of polycaprolactone, polyamide fiber 6 parts, 3 parts of acrylic acid graft modified carbon nanotubes, 2 parts of indium oxide, 4 parts of itaconate, 2 parts of dicumyl peroxide, 1 part of ethylene-vinyl acetate copolymer, 4 parts of ergosterol, fluorine 2 parts sodium chloride, 3 parts ethylene bis stearamide, 4 parts vinyl acetate, 2 parts tetramethylthiuram disulfide, 4 parts ethoxylated alkylamine, 2-hydroxy-4-methoxy 2 parts of benzophenone.

[0022] The preparation method of the above-mentioned antistatic polybutene-based packaging film comprises the following preparation steps:

[0023] Step 1: Put modified carbon nanotubes, indium oxide, ergosterol, and sodium fluoride in a high-speed mixer, add tetramethylthiuram disulfide, 2-hydroxy-4-methoxybenzophenone and Vinyl acetate, mixed and stir...

Embodiment 2

[0028] An antistatic polybutene-based packaging film, prepared from the following components in parts by weight: 48 parts of polybutene, 21 parts of polybutylene succinate, 15 parts of polycaprolactone, polyamide fiber 12 parts, 8 parts of acrylic acid grafted modified carbon nanotubes, 8 parts of indium oxide, 10 parts of itaconate, 7 parts of dicumyl peroxide, 5 parts of ethylene-vinyl acetate copolymer, 11 parts of ergosterol, fluorine 5 parts of sodium chloride, 7 parts of ethylene bis stearamide, 8 parts of vinyl acetate, 6 parts of tetramethylthiuram disulfide, 9 parts of ethoxylated alkylamine, 2-hydroxy-4-methoxy Benzophenone 10 parts.

[0029] The preparation method of the above-mentioned antistatic polybutene-based packaging film comprises the following preparation steps:

[0030] Step 1: Put modified carbon nanotubes, indium oxide, ergosterol, and sodium fluoride in a high-speed mixer, add tetramethylthiuram disulfide, 2-hydroxy-4-methoxybenzophenone and Vinyl ace...

Embodiment 3

[0035] An antistatic polybutene-based packaging film, prepared from the following components in parts by weight: 40 parts of polybutene, 18 parts of polybutylene succinate, 11 parts of polycaprolactone, polyamide fiber 9 parts, 5 parts of acrylic acid grafted modified carbon nanotubes, 5 parts of indium oxide, 7 parts of itaconate, 3 parts of dicumyl peroxide, 3 parts of ethylene-vinyl acetate copolymer, 7 parts of ergosterol, fluorine 3 parts of sodium chloride, 5 parts of ethylene bis stearamide, 6 parts of vinyl acetate, 4 parts of tetramethylthiuram disulfide, 6 parts of ethoxylated alkylamine, 2-hydroxy-4-methoxy 6 parts of benzophenone.

[0036] The preparation method of the above-mentioned antistatic polybutene-based packaging film comprises the following preparation steps:

[0037] Step 1: Put modified carbon nanotubes, indium oxide, ergosterol, and sodium fluoride in a high-speed mixer, add tetramethylthiuram disulfide, 2-hydroxy-4-methoxybenzophenone and Vinyl acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com