A kind of perfluoroalkyl polyacrylate waterproofing agent, preparation method and application

A technology of perfluoroalkyl polyacrylate and perfluoroalkyl acrylate, which can be used in textiles and papermaking, fiber treatment, and liquid-repellent fibers, etc. The chain segments are easy to reorient, dump, and the matrix structure is exposed, etc., to achieve excellent waterproof effect, superior liquid repellency, and stable surface conformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

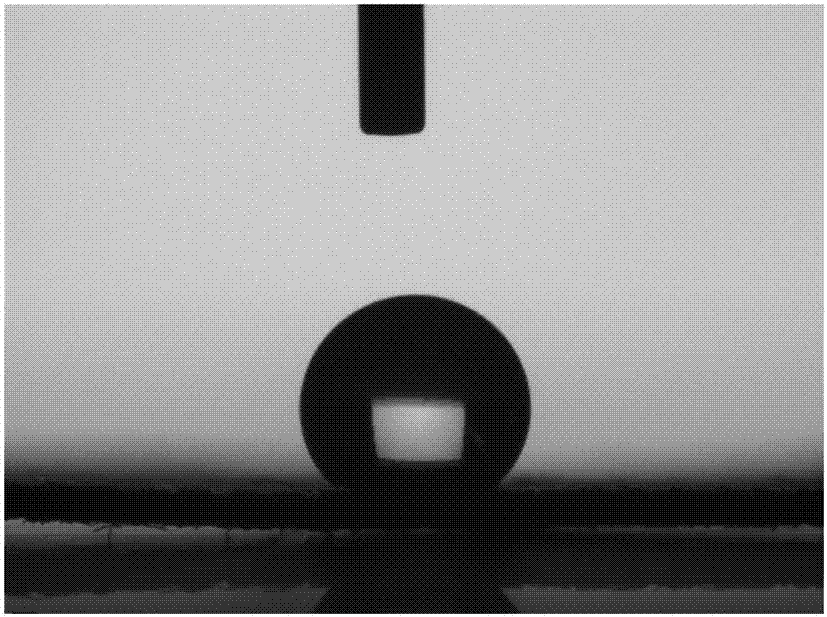

Image

Examples

Embodiment 1

[0058] 1. Synthesis of 1H, 1H, 2H, 2H-7-thia-perfluoroundecyl methacrylate

[0059] a. 46.9g of nonafluorobutyl tetrafluorosulfur bromide, 0.40g of di-tert-butyl peroxide, 0.4g of calcium carbonate and 48g of 1,3-bis(trifluoromethyl)benzene solvent were added to the reaction kettle, sealed, After evacuation, nitrogen was filled to replace the air in the reaction kettle, and then evacuation was carried out to replace. A total of 4 replacements. After being warming up to 45 ℃, tetrafluoroethylene is passed into this reactor for insulation, stirring reaction, and the control stirring rate is 55 rev / min, the feeding speed of tetrafluoroethylene is 12g / hour, and the pressure is 0.48MPa, and stops after 2 hours Tetrafluoroethylene was introduced, and the reaction was continued for 2 hours. After cooling, 1,3-bis(trifluoromethyl)benzene was removed from the reaction mixture by distillation under reduced pressure. The product thiaperfluorononyl bromide is obtained.

[0060] b. 65....

Embodiment 2

[0077] 1. Synthesize 1H, 1H, 2H, 2H-7-thia-perfluoroundecyl methacrylate according to Example 1

[0078] 2. Monomer pre-emulsion preparation

[0079] a. Add 1H, 1H, 2H, 2H-7-thia-perfluoroundecyl methacrylate 28.8g, 18.1g butyl acrylate, 9.1g methyl methacrylate and 2.6g to the tall beaker in turn g hydroxyethyl methacrylate is mixed to obtain a monomer mixture with good uniformity and fluidity.

[0080] b. Add 0.8g nonionic surfactant AEO-6 and 0.8g part cationic surfactant octadecyltrimethylammonium bromide into 110 parts deionized water, stir to dissolve, then add the above monomer mixture, 8000 High-speed shearing and stirring at rpm for 15 minutes to obtain a monomer pre-emulsion.

[0081] 3. Polymerization

[0082] a. Dissolve 0.7g of ammonium persulfate in 20g of deionized water to obtain an initiator solution for use.

[0083] b. Add the prepared monomer pre-emulsion into the reactor, heat it to 78°C, slowly add the prepared initiator solution dropwise, the droppin...

Embodiment 3

[0093] 1. Synthesis of 1H,1H,2H,2H-7-thia-perfluoroundecyl acrylate

[0094] a. Add 45.8g of nonafluorobutyltetrafluorosulfur bromide, 0.5g of dibenzoyl peroxide, 0.4g of calcium carbonate and 55g of trifluorotoluene solvent into the reaction kettle, seal it, vacuumize it, and fill it with nitrogen for replacement The air in the reactor was vacuumed and replaced. A total of 4 replacements were performed. After heating up to 45°C, feed tetrafluoroethylene into the reactor to keep warm and stir to react, control the stirring rate to 60 rpm, the feeding speed of tetrafluoroethylene to 13g / hour, the pressure to 0.50MPa, stop after 2 hours Tetrafluoroethylene was introduced, and the reaction was continued for 3 hours. After cooling, the reaction mixture was distilled off under reduced pressure to remove benzotrifluoride. The conditions of the reduced pressure distillation were a temperature of 50° C. and a vacuum degree of 20 mmHg. The product thiaperfluorononyl bromide was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com