Preparation method of 33 dtex/144f fine denier polyester fiber

A fine-denier yarn and polyester technology, which is applied in the field of polyester fine-denier yarn preparation, can solve the problems of difficult to reflect the intrinsic characteristics of ultra-fine denier fibers, high production difficulty, and low linear density, so as to improve added value and competitiveness, Customer service poor mechanical properties, the effect of small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

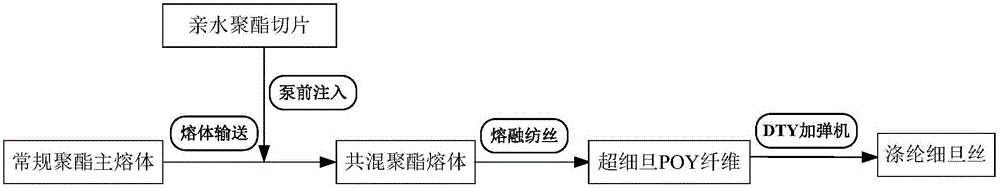

[0050] Please see attached figure 1 , is a process flow diagram of the present invention;

[0051] A kind of preparation method of the polyester fine denier silk of 33dtex / 144f, its concrete steps are:

[0052] 1. Preparation of hydrophilic polyester chips

[0053] (1) Preparation of hydrophilic modifier:

[0054] Using nano-silica powder as raw material, high-speed stirring and ultrasonic dispersion are carried out in N, N-dimethylpyrrolidone solution under normal temperature conditions. The dispersion time is 6-12 hours, and the high-speed stirring speed is 3000-4000 rpm , and then in a nitrogen atmosphere, add toluene diisocyanate, and react at a reaction temperature of 135 to 155°C for 45 to 60 minutes. Dry at 120° C. for 48 hours to prepare a hydrophilic modifier.

[0055] Among them, the average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N,N-dimethylpyrrolidone is 25g / L, toluene diisocyanate toluene diisocyanate ...

Embodiment 2

[0076] A kind of preparation method of the polyester fine denier silk of 33dtex / 144f, its concrete steps are:

[0077] 1. Preparation of hydrophilic polyester chips

[0078] (1) Preparation of hydrophilic modifier:

[0079] Using nano-silica powder as raw material, high-speed stirring and ultrasonic dispersion are carried out in N, N-dimethylpyrrolidone solution under normal temperature conditions. The dispersion time is 6-12 hours, and the high-speed stirring speed is 3000-4000 rpm , and then in a nitrogen atmosphere, add toluene diisocyanate, and react at a reaction temperature of 135 to 155°C for 45 to 60 minutes. Dry at 120° C. for 48 hours to prepare a hydrophilic modifier.

[0080] Among them, the average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N, N-dimethylpyrrolidone is 30g / L, toluene diisocyanate toluene diisocyanate and nano-silica The molar ratio is 1:8.

[0081] The surface of silica has an excellent hyd...

Embodiment 3

[0101] A kind of preparation method of the polyester fine denier silk of 33dtex / 144f, its concrete steps are:

[0102] 1. Preparation of hydrophilic polyester chips

[0103] (1) Preparation of hydrophilic modifier:

[0104] Using nano-silica powder as raw material, high-speed stirring and ultrasonic dispersion are carried out in N, N-dimethylpyrrolidone solution under normal temperature conditions. The dispersion time is 6-12 hours, and the high-speed stirring speed is 3000-4000 rpm , and then in a nitrogen atmosphere, add toluene diisocyanate, and react at a reaction temperature of 135 to 155°C for 45 to 60 minutes. Dry at 120°C for 48 hours to prepare a hydrophilic modifier;

[0105] Among them, the average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N,N-dimethylpyrrolidone is 38g / L, toluene diisocyanate toluene diisocyanate and nano-silica The molar ratio is 10.

[0106]The surface of silica has an excellent hydroxyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com