Water-based cleaning agent applied to cleaning hastelloy alloy strips and ultrasonic cleaning method

The technology of a water-based cleaning agent and a Hastelloy alloy is applied in the field of electrochemical polishing technology, which can solve the problems of low energy consumption, and achieve the effects of low energy consumption, simple process, and fast and sensitive detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

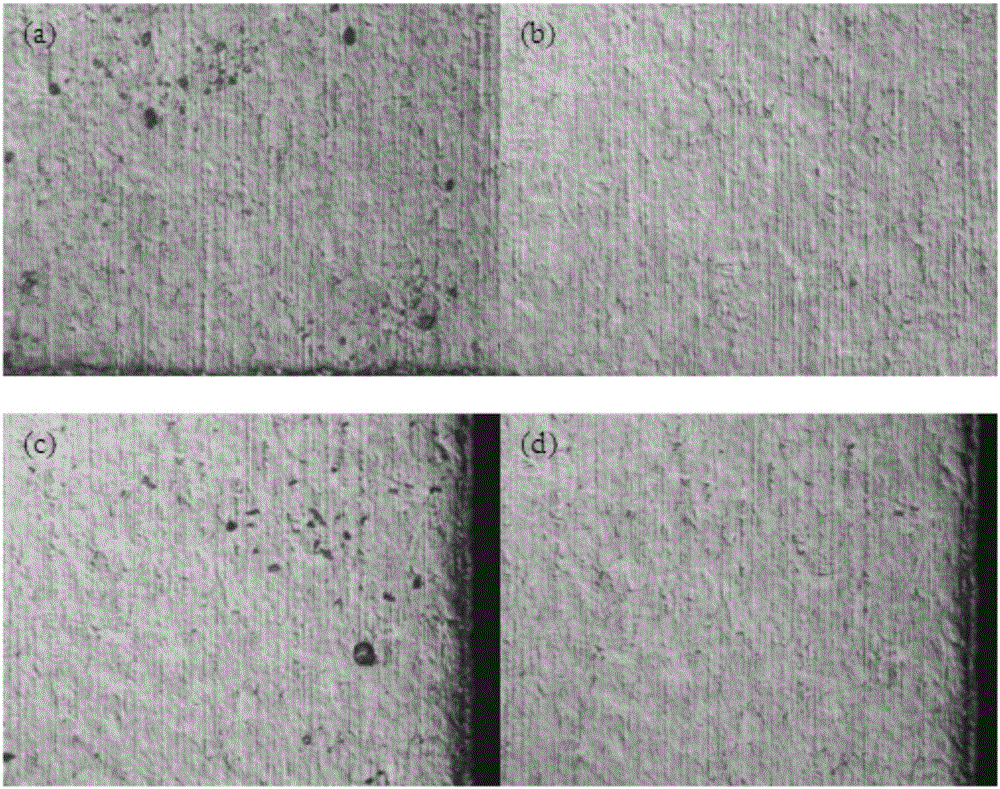

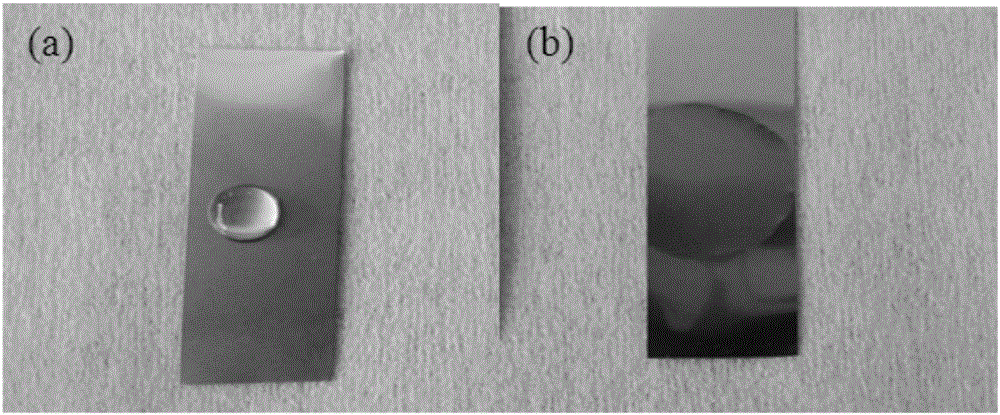

Image

Examples

Embodiment 1

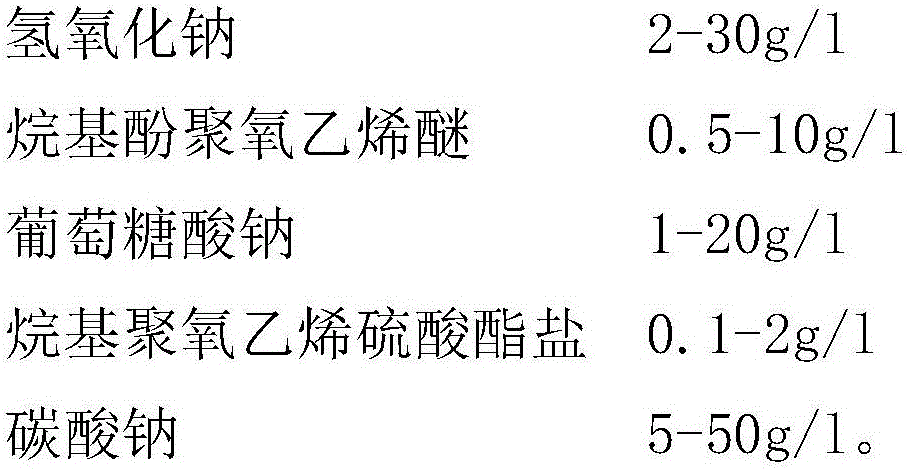

[0034] A formulation of a water-based cleaning agent is disclosed in Example 1, which can be used to clean Hastelloy strips in an ultrasonic field environment, and includes the following components in the formulation:

[0035] Sodium hydroxide (NaOH): 2g / l, alkylphenol polyoxyethylene ether (OP-10): 0.5g / l, sodium gluconate (C 6 h 11 NaO 7 ): 20g / l, alkyl polyoxyethylene sulfate (AES): 2g / l, sodium carbonate (NaCO 3 ): 50g / l.

[0036] The water-based cleaning agent in the present embodiment cleans the strip, and the specific method steps are as follows:

[0037] Step 1. Prepare 1000ml of solution according to the above water-based cleaning agent formula, dissolve all components in the solution completely, and filter to remove dirt and impurities in the solution.

[0038] Step 2. Cut the base strip of Hastelloy strip C-276 to 30cm, fold the base strip in half, put it into a cleaning dish filled with cleaning solution, and cover it with filter paper to prevent dust.

[0039...

Embodiment 2

[0043] A formulation of a water-based cleaning agent is disclosed in Example 2, which can be used to clean Hastelloy strips in an ultrasonic field environment, and includes the following components in the formulation:

[0044] Sodium hydroxide (NaOH): 30g / l, alkylphenol polyoxyethylene ether (OP-10): 10g / l, sodium gluconate (C 6 h 11 NaO 7 ): 1g / l, alkyl polyoxyethylene sulfate (AES): 0.1g / l, sodium carbonate (NaCO 3 ): 5g / l.

[0045] The water-based cleaning agent in the present embodiment cleans the strip, and the specific method steps are as follows:

[0046] Step 1. Prepare 1000ml of solution according to the above water-based cleaning agent formula, dissolve all components in the solution completely, and filter to remove dirt and impurities in the solution.

[0047] Step 2. Cut the base strip of Hastelloy strip C-276 to 30cm, fold the base strip in half, put it into a cleaning dish filled with cleaning solution, and cover it with filter paper to prevent dust.

[0048...

Embodiment 3

[0052] A formulation of a water-based cleaning agent is disclosed in Example 3, which can be used to clean Hastelloy strips in an ultrasonic field environment, and includes the following components in the formulation:

[0053] Sodium hydroxide (NaOH): 16g / l, alkylphenol polyoxyethylene ether (OP-10): 5g / l, sodium gluconate (C 6 h 11 NaO 7 ): 10g / l, alkyl polyoxyethylene sulfate (AES): 1g / l, sodium carbonate (NaCO 3 ): 27g / l.

[0054] The water-based cleaning agent in the present embodiment cleans the strip, and the specific method steps are as follows:

[0055] Step 1. Prepare 1000ml of solution according to the above water-based cleaning agent formula, dissolve all components in the solution completely, and filter to remove dirt and impurities in the solution.

[0056] Step 2. Cut the base strip of Hastelloy strip C-276 to 30cm, fold the base strip in half, put it into a cleaning dish filled with cleaning solution, and cover it with filter paper to prevent dust.

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com