Alkoxy ether thermosensitive chiral polymer nano-microspheres and preparation method thereof

A technology of nano-microspheres and alkoxy ethers, which is applied in the field of alkoxy-ether thermosensitive chiral polymer nano-microspheres and its preparation, can solve the problems of stabilizing single-chiral nano-microspheres, which have not been reported, and achieve excellent results. Temperature-sensitive behavior, stable and single conformation, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] For the preparation method of the first-generation alkoxyether dendron, please refer to the literature Li, W.; Zhang, A.; Schlüter, A. D. Chem. Commun. 2008, 5523 and Yan J T; Liu K; Wu D L; Chen F; Wu P Y; Zhang A. Chem. Asian J. , 2011, 6, Synthesis of 3260.

[0029] For the preparation method of p-alkynylbenzaldehyde, please refer to the literature Zhang, Y; Gao, K; Zhao, Z; Yue, D; Hu, Y; Masuda T. J. Polym. Science. Part A: Polym. Chem. , 2013, 51(24), 5248 Synthesis.

[0030] For the preparation method of p-alkynylbenzoic acid, please refer to literature E, Yashima; T, Matsushima; and Y, Okamoto. J. Am. Chem. Soc., 1997, 119 (27), 6345 Synthesis.

[0031] The preparation method of pentafluorophenol active ester of p-alkynylbenzoic acid refers to the literature B. Z. Tang, et al. Macromolrcules, 2011, 6724.

[0032] The preparation method of PA-N-ALA-G1-Et refers to the patent Zhang Afang. Polyphenylene vinylene derivatives with reversible regulation of tempe...

Embodiment 1

[0033] Embodiment one: concrete steps are:

[0034] 1. Synthesis of Polymer P(PA-N-ALA-G1-Et-co-PA-CHO)

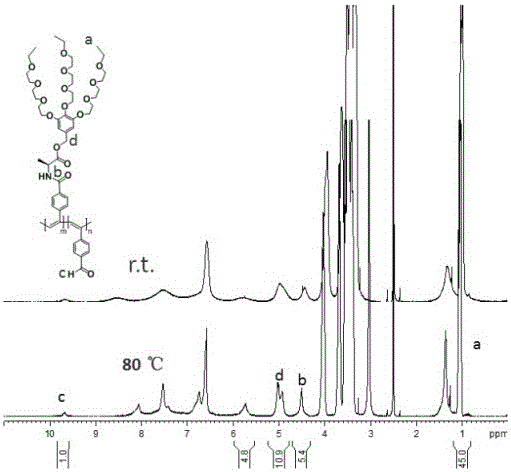

[0035] Weigh p-alkynylbenzaldehyde and the alkoxyether first-generation dendritic phenylacetylene macromonomer containing chiral inducing groups at a molar ratio of 5:1 and dissolve them in a small amount of dry tetrahydrofuran, slowly add 1 / 50 equivalents of [Rd(nbd)Cl] aged and added dropwise with 1 drop of triethylamine 2 THF solution, the reaction was stirred at room temperature for 5 hours until the reaction was complete. After the THF was spin-dried, DCM was used to purify the crude product by column chromatography to obtain the target copolymer. attached by figure 2 1 HNMR at room temperature and high temperature (DMSO, 25ºC, 80ºC): By integrating the aldehyde group and comparing the ratio of the hydrogen of the methylene group on the side group of the methine group and the first-generation alkoxyether side group of the amino acid, and the methyl group of the...

Embodiment 2

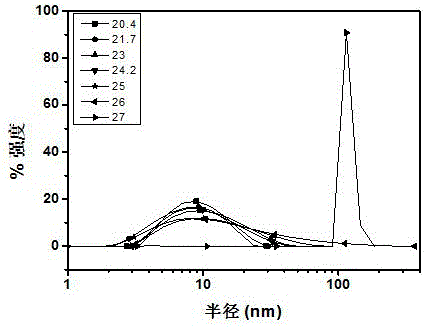

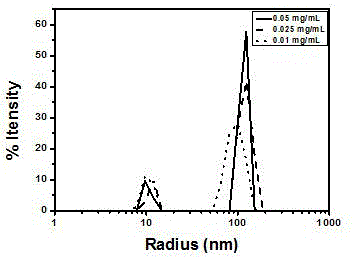

[0039] The size of the copolymer and the polymer nanospheres in aqueous solution were characterized by dynamic light scattering. as attached image 3 As shown, at room temperature (lower than 27°C), the size radius of the copolymer is about 10nm, and the dispersion is wide. When the temperature reaches 27°C, the polymer begins to dehydrate, followed by chain segment collapse and aggregation, forming aggregates with a narrow distribution of about 100nm. attached Figure 4 For the prepared polymer nanospheres, after diluting from 0.05mg / ml to 0.025mg / ml, 0.01mg / ml, dynamic light scattering shows that it basically maintains about 100nm. Therefore, it was proved that the polymer nanospheres were successfully prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com