Semi-automatic 3D spherical milling-grinding machine

A kind of milling machine, semi-automatic technology, applied in the direction of spherical grinding machine, grinding frame, grinding machine tool parts, etc., can solve the problems of not being able to fit the equipment head tightly, affecting the strength of the pipeline, and large grinding volume, etc., to achieve Save manpower and time cost, reasonable structure design, stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

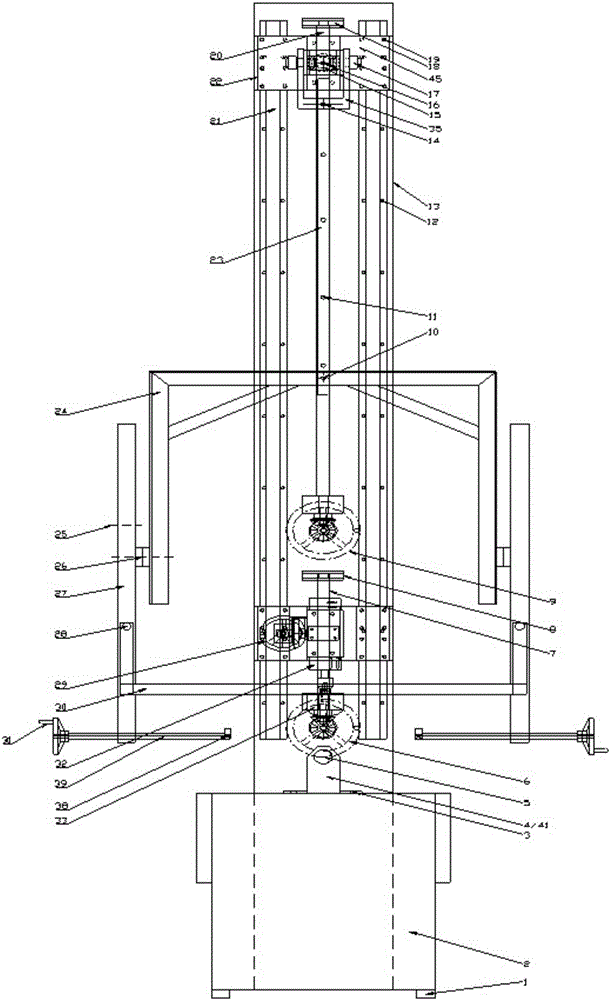

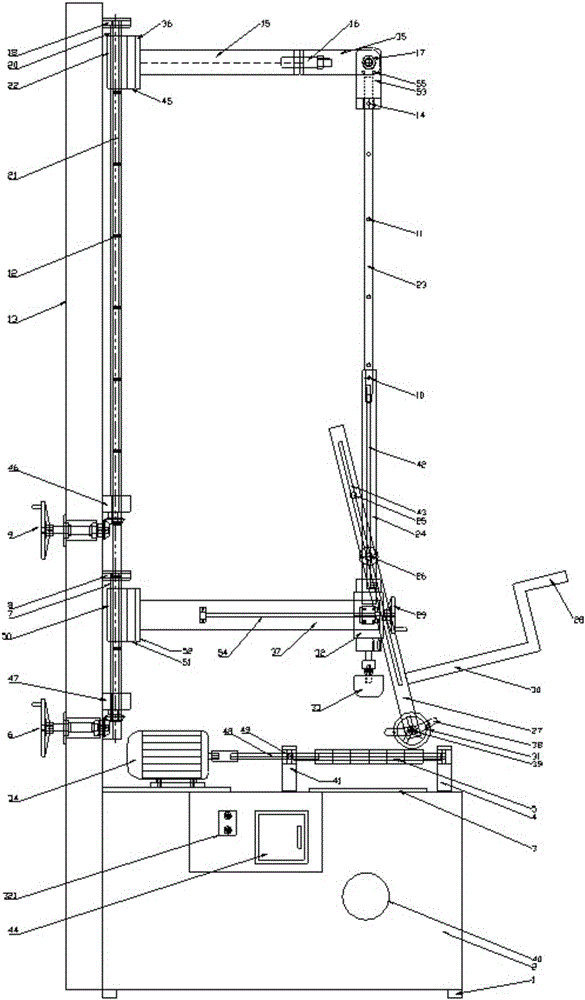

[0024] Such as figure 1 , figure 2 As shown, the semi-automatic 3D spherical milling machine of the present invention is characterized in that it is provided with: a support box 2, and the top surface of the support box is respectively connected with a grinding wheel rod motor 34, a front grinding wheel seat 4, a rear Wheel base 41, a leaker 3;

[0025] The support box 2 is a hollow box, and the leaker 3 communicates with the inside of the support box; the rotating shaft 48 of the grinding wheel rod motor 34 is connected with the grinding wheel rod bearing 49 that passes through the front grinding wheel seat 4 and the rear grinding wheel seat, and the grinding wheel rod A grinding wheel rod 5 is sleeved on the rotating shaft 48 of the motor; the outer wall of the support box 2 is connected with the main grinding wheel motor switch 321 and a grinding wheel rod motor switch 44 by bolts and offers a dust suction port 40, which is connected to the vacuum cleaner Connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com