Production system and production method used for large-size titanium and titanium alloy square and rectangular pipes

A production system, titanium alloy technology, applied in metal rolling, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy fracturing, hazards, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

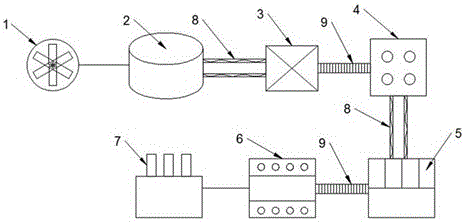

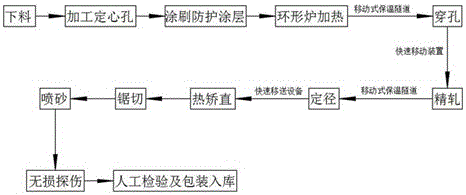

[0110] A kind of thermal processing production method of titanium and titanium alloy square tube, is processed into the tube blank of TA1, TA2, TA3, TA4, TA5, TA6 and TA7 brand, comprises following process:

[0111] 1) Cutting: Cut the titanium and titanium alloy blanks according to the length required by the production, and process the cut blanks to the corresponding outer diameter according to the production requirements, and at the same time ensure that the surface roughness after processing is Ra≤3.2μm. The material is completed to obtain a qualified titanium alloy tube blank;

[0112] 2) Centering hole: Use the centering machine 1 to process the centering hole on both ends of the tube blank;

[0113] 3) Apply protective coating: apply protective coating to the surface of the tube blank;

[0114] 4) Heating: put the tube billet in the ring heating furnace 2 and heat it in sections, the heating speed of the low-temperature slow section is 10min / cm, and the heating speed of...

Embodiment 2

[0129] The production method for large-size titanium and titanium alloy square tubes, the grades are TA8, TA8-1, TA9, TA9-1, TA10, TA13, TA15, TA18 tube blanks, including the following processes:

[0130] 1) Cutting: Cut the titanium and titanium alloy blanks according to the length required by the production, and process the cut blanks to the corresponding outer diameter according to the production requirements, and at the same time ensure that the surface roughness after processing is Ra≤3.2μm. The material is completed to obtain a qualified titanium alloy tube blank;

[0131] 2) Centering hole: Use the centering machine 1 to process the centering hole on both ends of the tube blank;

[0132] 3) Apply protective coating: apply protective coating to the surface of the tube blank;

[0133] 4) Heating: put the tube billet in the ring heating furnace 2 and heat it in sections, the heating speed of the low-temperature slow section is 10min / cm, and the heating speed of the high-t...

Embodiment 3

[0148] The production method for large-size titanium and titanium alloy square tubes, the grades are TC1, TC2, TC3, TC4, TC10 tube blanks, including the following processes:

[0149] 1) Cutting: Cut the titanium and titanium alloy blanks according to the length required by the production, and process the cut blanks to the corresponding outer diameter according to the production requirements, and at the same time ensure that the surface roughness after processing is Ra≤3.2μm. The material is completed to obtain a qualified titanium alloy tube blank;

[0150] 2) Centering hole: Use the centering machine 1 to process the centering hole on both ends of the tube blank;

[0151] 3) Apply protective coating: apply protective coating to the surface of the tube blank;

[0152] 4) Heating: put the tube billet in the ring heating furnace 2 and heat it in sections, the heating speed of the low-temperature slow section is 10min / cm, and the heating speed of the high-temperature fast sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com