Novel multifunctional skin protection material and preparation method and application thereof

A multifunctional, fiber composite material technology, used in textiles and papermaking, bandages, animal fibers, etc., can solve the problems of difficult recycling, heavy load, inconvenience to carry, etc., achieve excellent catalytic digestion efficiency, good stability, and promote wound healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

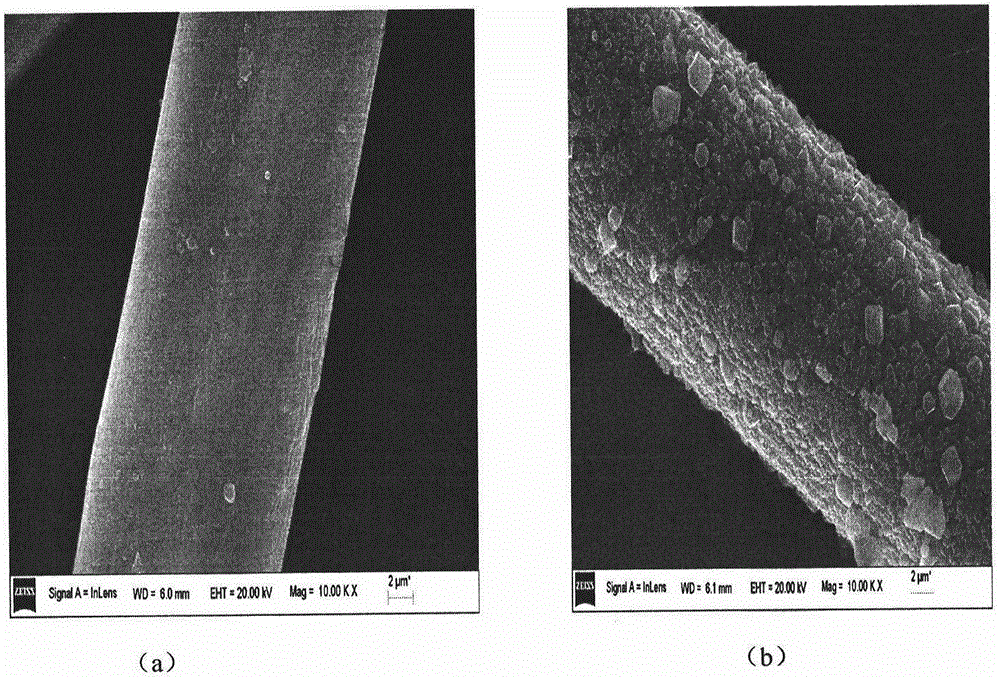

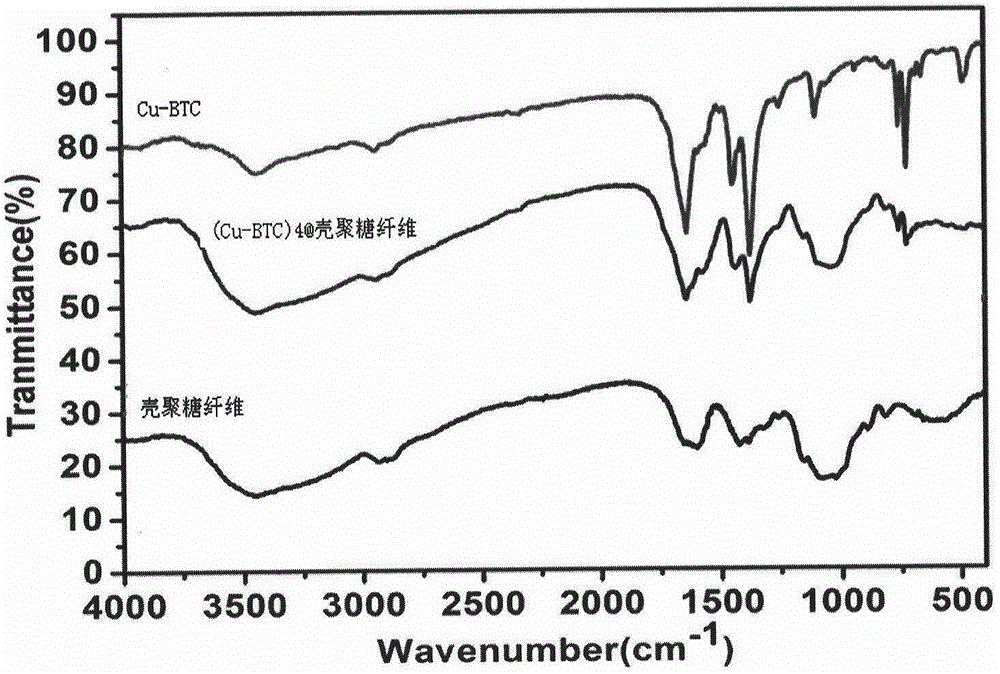

[0015] 1) Dissolve 2.0g of sodium hydroxide in 38.0g of water to obtain a 5wt.% NaOH solution, then add 4.7g of sodium chloroacetate. After dissolving, immerse 0.12g of chitosan fibers in sodium chloroacetate solution for carboxylation treatment, take out the chitosan fibers after 1h, and wash off the unreacted residual liquid on the fiber surface with 40mL of distilled water;

[0016] 2) Dissolve 0.20g of copper acetate monohydrate and 0.11g of 1,3,5-benzenetricarboxylic acid in 100mL of absolute ethanol;

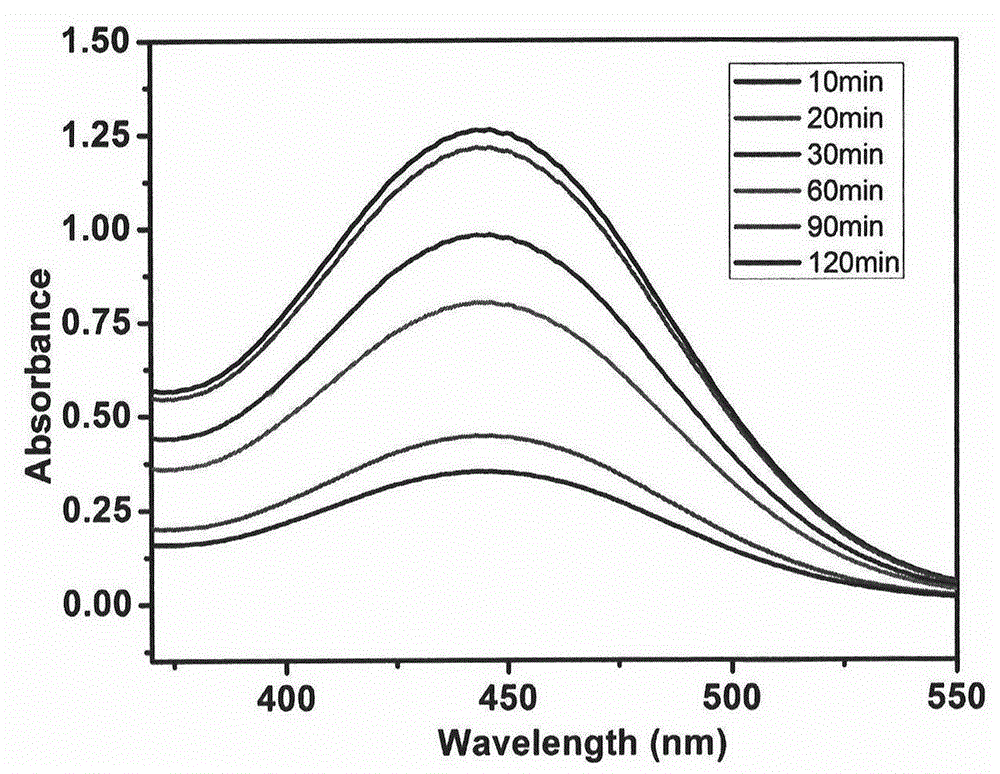

[0017] 3) the chitosan fibers after the treatment in step 1) are immersed alternately in the ethanol solution of copper acetate in step 2) and in the ethanol solution of 1,3,5-benzenetricarboxylic acid for each 20min, after each soaking, the shell The polysaccharide fibers were soaked and washed in absolute ethanol for 2 min. Four layers of Cu-BTC can be loaded on the surface of chitosan fibers after four alternate immersion cycles in the ethanol solution of copper acetat...

Embodiment 2

[0020] 1) Dissolve 2.0g of sodium hydroxide in 38.0g of water to obtain a 5wt.% NaOH solution, then add 4.7g of sodium chloroacetate. After dissolving, immerse 0.10g of chitosan fibers in sodium chloroacetate solution for carboxylation treatment, take out the chitosan fibers after 1h, and wash off the unreacted residual liquid on the fiber surface with 40mL of distilled water;

[0021] 2) Dissolve 0.40g of copper acetate monohydrate and 0.21g of 1,3,5-benzenetricarboxylic acid in 200mL of absolute ethanol;

[0022] 3) the chitosan fibers after the treatment in step 1) are immersed alternately in the ethanol solution of copper acetate in step 2) and in the ethanol solution of 1,3,5-benzenetricarboxylic acid for each 20min, after each soaking, the shell The polysaccharide fibers were soaked and washed in absolute ethanol for 2 min. After eight alternate immersion cycles in ethanol solutions of copper acetate and 1,3,5-benzenetricarboxylic acid, eight layers of Cu-BTC can be loa...

Embodiment 3

[0025] 1) Dissolve 2.0g of sodium hydroxide in 38.0g of water to obtain a 5wt.% NaOH solution, then add 4.7g of sodium chloroacetate. After dissolving, immerse 0.10 g of calcium and sodium alginate fiber in sodium chloroacetate solution for carboxylation treatment, take out the calcium and sodium alginate fiber after 1 hour, and wash off the unreacted residual liquid on the surface of the fiber with 40 mL of distilled water;

[0026] 2) Dissolve 0.20g of copper acetate monohydrate and 0.11g of 1,3,5-benzenetricarboxylic acid in 100mL of absolute ethanol;

[0027] 3) The calcium sodium alginate salt fibers treated in step 1) were alternately immersed in the ethanol solution of copper acetate in step 2) and the ethanol solution of 1,3,5-benzenetricarboxylic acid for 20 minutes each, after each soaking Soak and wash alginate calcium sodium salt fiber in absolute ethanol for 2 min. Four layers of Cu-BTC can be loaded on the surface of chitosan fibers after four alternate immersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com