A continuous flux melting method and device for magnesium and magnesium alloys

A magnesium alloy and flux technology, applied in the field of smelting methods and devices, can solve the problems of lack of heat transfer mechanism, prolong stirring and refining time, and inability to operate continuously, so as to avoid excessive pollution and waste, eliminate plant equipment corrosion, and eliminate moisture absorption The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

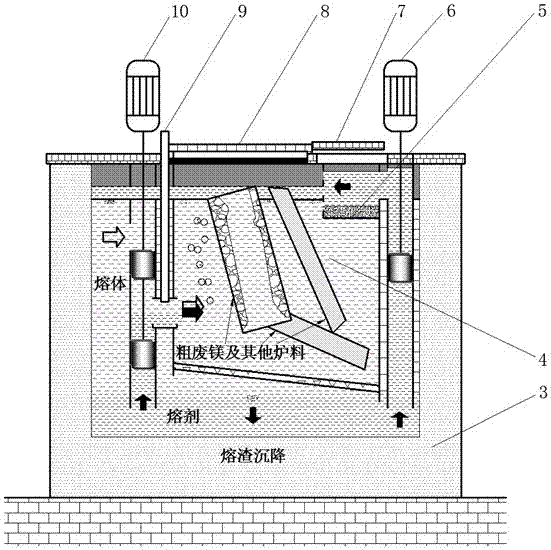

[0045] Coarse magnesium produced by the silicothermal reduction process generally has a loose outer layer of "dust + magnesium particles" and an inner layer of "crystalline magnesium" ( figure 1 ) structural characteristics, the thermal resistance of the surface layer is high and does not infiltrate with the melt, and there is a technical bottleneck of refractory melting, combined below figure 2 The application of the present invention in refining production of crude magnesium is introduced. The implementation device includes the following main components ( figure 2 ): crucible 3, melting chamber 4, flux filter 5, flux circulation purification pump 6, flux slag port 7, feed port 8, refining air pipe 9 and melting-promoting refining pump 10.

[0046] The crude magnesium charge is fed into the melting chamber 4 of the built-in molten flux crucible 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com