Environment-friendly efficient concentrated tin paste cleaning agent and preparation method thereof

A technology of concentrated solder paste and cleaning agent, applied in the field of cleaning agent, can solve the problems of hindering electrical connection, poor cleaning effect, solder paste deposition, etc., and achieve the effect of easy biodegradation, good cleaning effect, and reduced cleaning and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

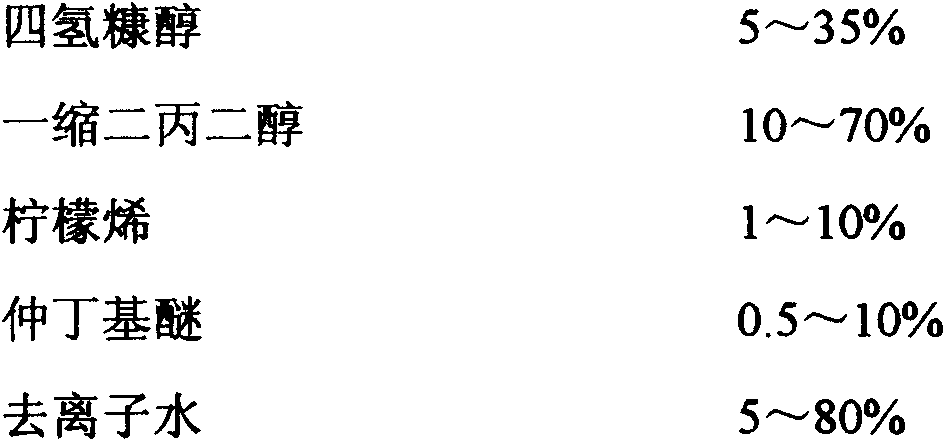

[0015] An environmentally-friendly high-efficiency concentrated solder paste cleaning agent, which is characterized in that it comprises the following components by weight ratio:

[0016]

[0017] The preparation method of the environment-friendly high-efficiency concentrated solder paste cleaning agent includes the following steps:

[0018] (1) Put an appropriate amount of deionized water into the agitator, and then slowly add tetrahydrofurfuryl alcohol, dipropylene glycol, limonene, and sec-butyl ether under stirring;

[0019] (2) Increase the speed to 1000-1200 rpm, and stir for 15-25 minutes.

Embodiment 2

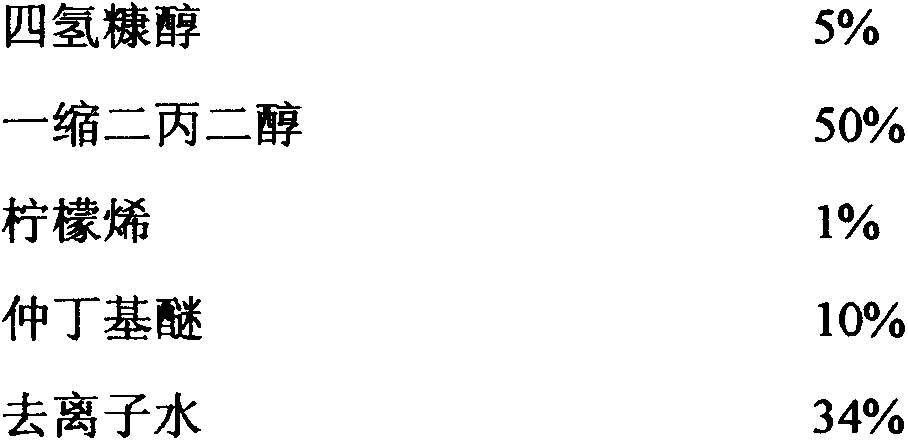

[0021] An environmentally-friendly high-efficiency concentrated solder paste cleaning agent, which is characterized in that it comprises the following components by weight ratio:

[0022]

[0023]

[0024] The preparation method of the environment-friendly high-efficiency concentrated solder paste cleaning agent is the same as that of Example 1.

Embodiment 3

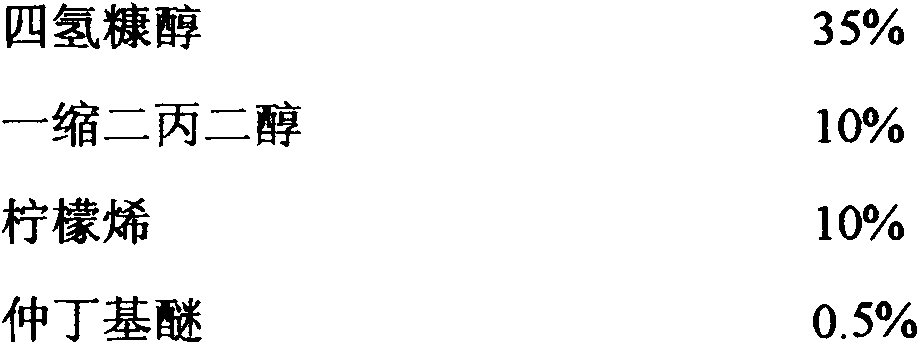

[0026] An environmentally-friendly high-efficiency concentrated solder paste cleaning agent, which is characterized in that it comprises the following components by weight ratio:

[0027]

[0028] The preparation method of the environment-friendly high-efficiency concentrated solder paste cleaning agent is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com