Self-repairing water-based super-hydrophobic coating based on microcapsule type and preparing method thereof

A super-hydrophobic coating and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve environmental pollution and other problems, and achieve the effect of no VOC emission, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

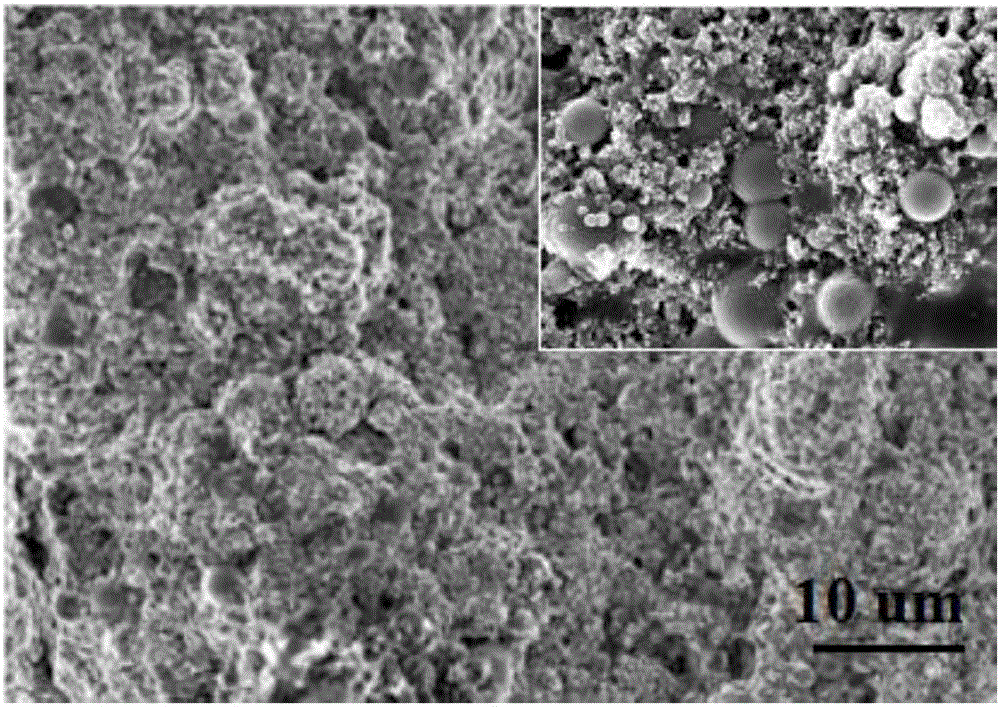

[0041](1) In a 250mL beaker, first add 100mL of water and ethanol mixture (1:1 by volume) and 1.2 parts of heptadecafluorodecyltrimethoxysilane (FAS17), stir well and then add 4.5 parts of Al 2 o 3 Nanoparticles and 0.6 parts of ammonia water, after ultrasonication for 10 minutes, stirred and reacted at a temperature of 60 °C for 24 hours to obtain modified Al 2 o 3 Nanoparticles. Finally, the modified Al 2 o 3 The ethanol in the nanoparticle solution was rotary evaporated, and redispersed with 45mL deionized water for later use.

[0042] (2) Add 4 parts of styrene, 0.4 parts of divinylbenzene, 0.12 parts of azobisisobutyronitrile and 2 parts of FAS17 into a 250mL three-necked flask, stir well, then add 0.3 parts of sodium dodecylbenzenesulfonate and 200mL deionized water, sonication for 30min, and stirring at 70°C for 20h to obtain FAS17-coated microcapsules.

[0043] (3) the hydrophobic nanometer Al of step (1) gained 2 o 3 38 parts of aqueous solution, 25 parts of m...

Embodiment 2

[0045] (1) In a 250mL beaker, first add 130mL of water and ethanol mixture (volume ratio: 2:1) and 1.5 parts of tridecafluorooctyltriethoxysilane (FAS13), stir well, and then add 5 parts of gas phase two Silicon oxide and 1 part of ammonia water were ultrasonicated for 5 minutes, then stirred and reacted at a temperature of 65° C. for 20 hours to obtain modified silicon dioxide. Finally, the ethanol in the modified silica solution was rotary-evaporated, and re-dispersed with 50 mL of deionized water for later use.

[0046] (2) First add 24 parts of polystyrene solution (concentration: 25%, dichloromethane as solvent) and 4.5 parts of FAS13 in a 200mL single-necked flask, after stirring evenly, add 100mL of deionized water and 1.72 parts of dodecylbenzene Sodium sulfonate, then sonicate for 10 minutes, and then stir at 30°C for 6 hours to obtain coated FAS13 microcapsules.

[0047] (3) the hydrophobic nano-SiO obtained in step (1) 2 43 parts of aqueous solutions, 18 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com