A kind of water-based polyurethane emulsion with yellowing resistance and high film hardness and preparation method thereof

A water-based polyurethane and anti-yellowing technology, applied in the field of water-based polyurethane emulsion, can solve the problems of reduced product strength, poor drying speed, poor synergy effect, etc., to achieve broad market prospects, improve drying speed, and improve the effect of modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

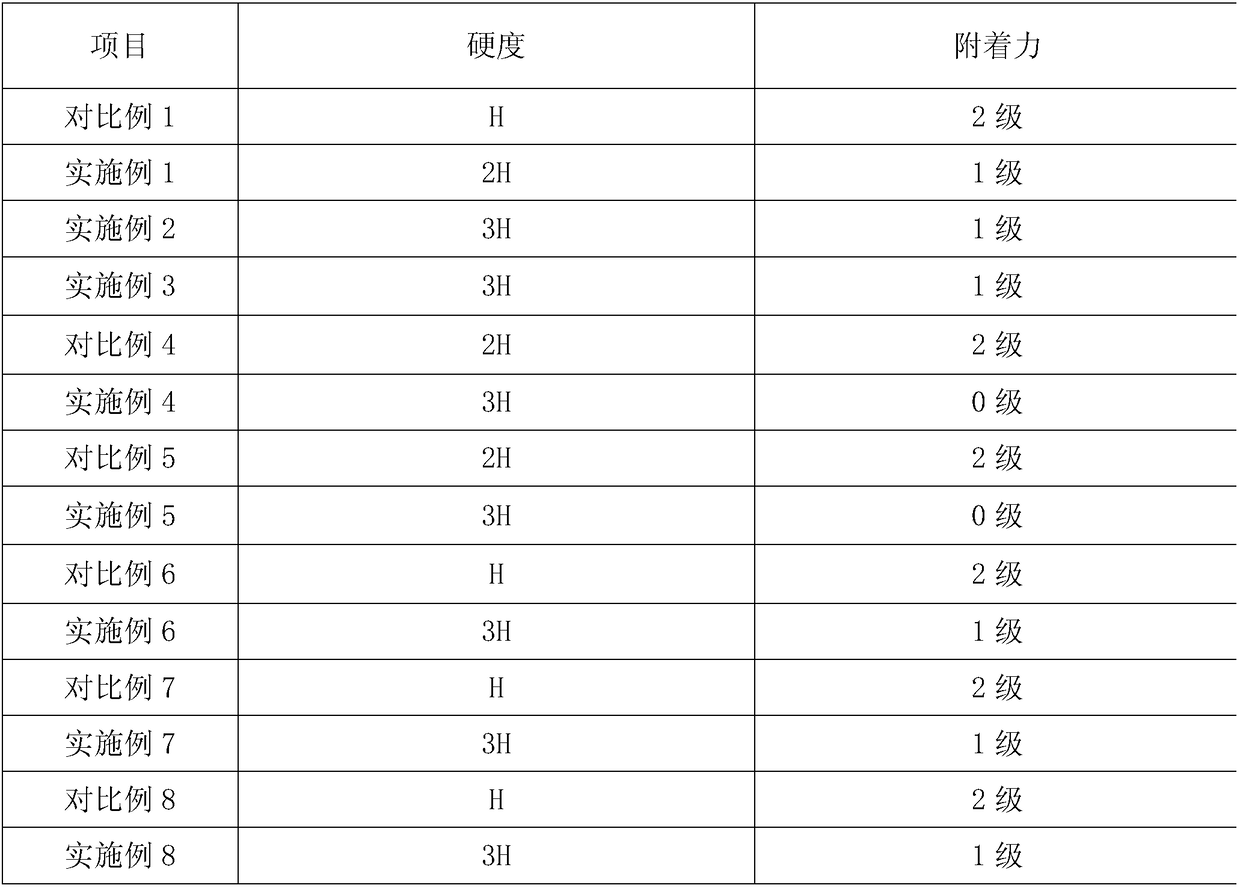

Examples

Embodiment 1

[0028] (1) Add 100 parts by weight of deionized water into the reactor, add 1 part by weight of sodium dodecylsulfonate emulsifier, 1 part by weight of ammonium persulfate initiator, then add 3.84 parts by weight of methyl methacrylate, acrylic acid 0.24 parts by weight of n-octyl ester, 1.44 parts by weight of butyl acrylate, 0.24 parts by weight of acrylic acid, 0.24 parts by weight of hydroxyethyl acrylate, polymerized at 70°C for 0.5 hours, and then added dropwise 34.56 parts by weight of methyl methacrylate, n-acrylic acid 2.16 parts by weight of octyl ester, 12.96 parts by weight of butyl acrylate, 2.16 parts by weight of acrylic acid, and 2.16 parts by weight of hydroxyethyl acrylate, polymerized for 5 hours, and finally raised the temperature to 85° C., reacted for 2 hours, and cooled to room temperature to obtain a polyacrylate emulsion.

[0029](2) get molecular weight 3000, functionality is 60 weight parts of carbon dioxide base copolymer polyol of 2, isophorone diis...

Embodiment 2

[0032] Take 80 parts by weight of the aqueous polyurethane emulsion prepared in Example 1, add 20 parts by weight of the acrylate emulsion prepared in Example 1, and emulsify at room temperature for 1 hour at high speed to obtain a polyacrylate modified aqueous polyurethane emulsion.

Embodiment 3

[0034] Take 70 parts by weight of the water-based polyurethane emulsion prepared in Example 1, and 30 parts by weight of the polyacrylate emulsion prepared in Example 1, and emulsify at room temperature for 1 hour at high speed to obtain a polyacrylate-modified water-based polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com