A preparation method of high specific surface area carbon microspheres based on Camellia oleifera seed shell

A technology with high specific surface area and camellia oleifera seed shell, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as inability to achieve mass production and green preparation, demanding equipment and operation requirements, and complicated raw material source process. Achieve the effect of low cost, regular shape and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

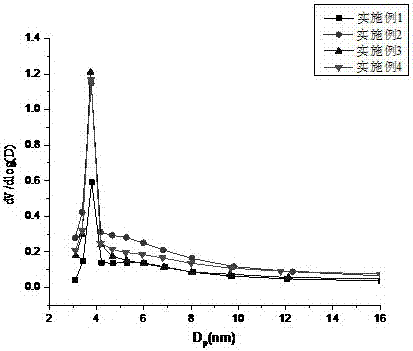

Embodiment 1

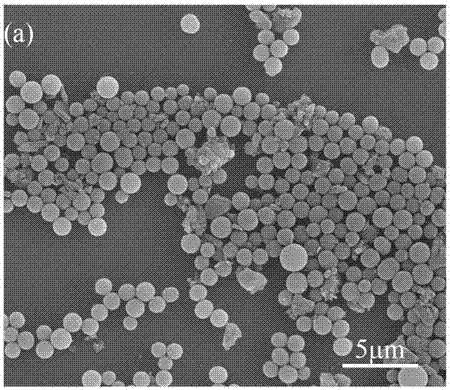

[0026] Put 1.6g of Camellia oleifera seed shell powder with a particle size of 74 μm and 0.4g of phloroglucinol in a 250ml beaker, add 60mL of deionized water, and stir magnetically for 6h. Transfer to a 100mL polytetrafluoroethylene-lined reactor, and react in a blast oven at 230°C for 12h. After naturally cooling to room temperature, the solids were separated by vacuum filtration, washed alternately with deionized water and absolute ethanol several times, and dried in a blast drying oven at 60°C to obtain hydrothermal carbon microspheres.

[0027] Put 1 g of hydrothermal carbon microspheres in an alumina porcelain boat, anneal in a high-temperature tube furnace, raise the temperature to 650 °C at 5 °C / min, keep the temperature for 2 hours, and then cool down to room temperature naturally to obtain annealed carbon microspheres. The annealing process uses an argon atmosphere for protection.

[0028] Take 0.3g of annealed carbon microspheres and 0.3g of potassium hydroxide sol...

Embodiment 2

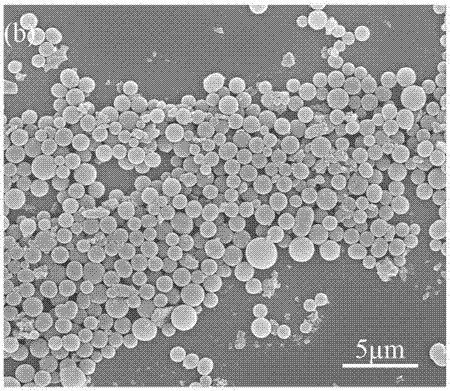

[0031] Put 1.6g of Camellia oleifera seed shell powder with a particle size of 74 μm and 0.4g of phloroglucinol in a 250ml beaker, add 60mL of deionized water, and stir magnetically for 6h. Transfer to a 100mL polytetrafluoroethylene-lined reactor, and react in a blast oven at 230°C for 12h. After naturally cooling to room temperature, the solids were separated by vacuum filtration, washed alternately with deionized water and absolute ethanol several times, and dried in a blast drying oven at 60°C to obtain hydrothermal carbon microspheres.

[0032] Put 1 g of hydrothermal carbon microspheres in an alumina porcelain boat, anneal in a high-temperature tube furnace, raise the temperature to 650 °C at 5 °C / min, keep the temperature for 2 hours, and then cool down to room temperature naturally to obtain annealed carbon microspheres. The annealing process uses an argon atmosphere for protection.

[0033] Take 0.3g of annealed carbon microspheres and 0.6g of potassium hydroxide sol...

Embodiment 3

[0036] Put 1.6 g of camellia oleifera seed shell powder with a particle size of 74 μm and 0.4 g of phloroglucinol in a 250 mL beaker, add 60 mL of deionized water, and stir magnetically for 6 h. Transfer to a 100mL polytetrafluoroethylene-lined reactor, and react in a blast oven at 230°C for 12h. After naturally cooling to room temperature, the solids were separated by vacuum filtration, washed alternately with deionized water and absolute ethanol several times, and dried in a blast drying oven at 60°C to obtain hydrothermal carbon microspheres.

[0037] Put 1 g of hydrothermal carbon microspheres in an alumina porcelain boat, anneal in a high-temperature tube furnace, raise the temperature to 650 °C at 5 °C / min, keep the temperature for 2 hours, and then cool down to room temperature naturally to obtain annealed carbon microspheres. The annealing process uses an argon atmosphere for protection.

[0038]Take 0.3g of annealed carbon microspheres and 0.6g of potassium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com