Peelable UV transfer printing decorative film for film coating colored board and preparation method of peelable UV transfer printing decorative film for film coating colored board

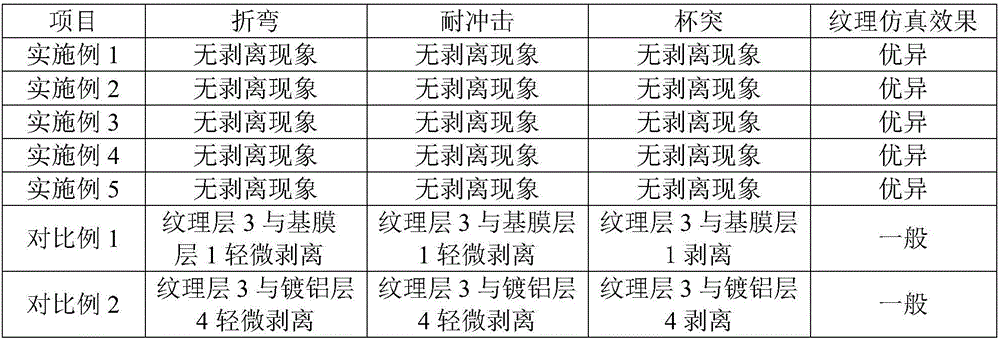

A decorative film and color plate technology, which is applied in the field of peelable UV transfer printing decorative film for coated color plates and its preparation, can solve the problems of product performance that cannot meet the requirements, peeling of the base film layer and the texture layer, and the separation of the aluminized layer and the texture layer. Problems such as texture layer peeling, to achieve outstanding test performance, reduce material costs, and good simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

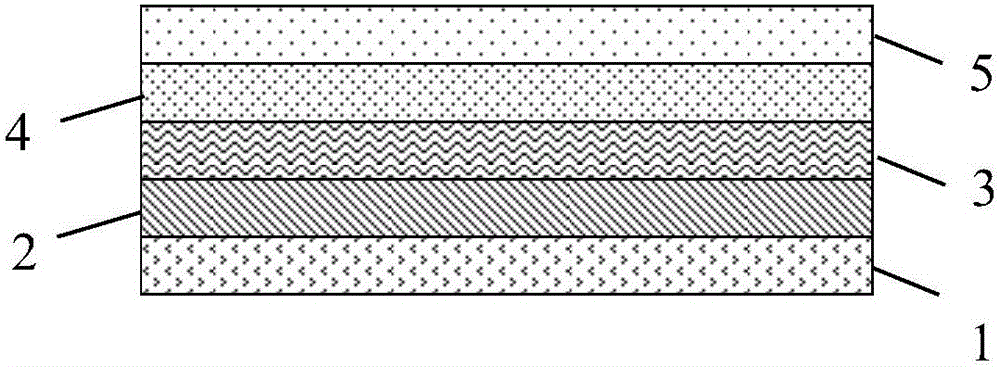

[0022] On the surface of the 50 μm thick PET (polyethylene terephthalate) base film layer 1 surface treated with corona, a micro-gravure coating method is used to form a silicone peeling layer 2 with a thickness of 1 μm, and then on the peeling layer 2. A brushed texture layer 3 with a thickness of 10 μm is formed by UV transfer printing, and then aluminum with a thickness of 10 nm is vapor-deposited on the brushed texture layer 3 to form an aluminum-coated layer 4, and then micro-gravure coating is used to form a vinyl acetate layer with a thickness of 1 μm. The ester is bonded to layer 5 to obtain a peelable UV transfer brushed texture decorative film.

Embodiment 2

[0024] On the surface of the untreated 30 μm thick PVC (polyvinyl chloride) base film layer 1, a polyurethane peeling layer 2 with a thickness of 0.5 μm is formed by slit extrusion coating, and then the UV transfer method is used on the peeling layer 2 Form a frosted texture layer 3 with a thickness of 2 μm, then sputter aluminum with a thickness of 5 nm on the frosted texture layer 3 to form an aluminum layer 4, and then form an acrylic adhesive layer 5 with a thickness of 0.5 μm by micro-gravure coating , to obtain a peelable UV transfer matte texture decorative film.

Embodiment 3

[0026] On the surface of the 45 μm thick PP (polypropylene) base film layer 1 surface chemically treated, a 1.5 μm acrylic resin peeling layer 2 with a thickness of 1.5 μm is formed by spray coating, and then a 50 μm thick film is formed on the peeling layer 2 by UV transfer printing. Fiber texture layer 3, then sputtering aluminum with a thickness of 12nm on the fiber texture layer 3 to form an aluminum coating layer 4, and then adopting a slot extrusion coating method to form a polyurethane adhesive layer 5 with a thickness of 2 μm to obtain a peelable UV Transfer printed fiber textured decorative film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com