Method for extracting residual solvent in packaging material, method for detecting residual solvent, kit for detecting residual solvent, and use of kit

A technology for packaging materials and residual solvents, applied in the field of analysis, can solve problems such as the inability to find a blank matrix for it, the inability to detect residual solvents in special-shaped packaging materials for cigarettes, and the hardness of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

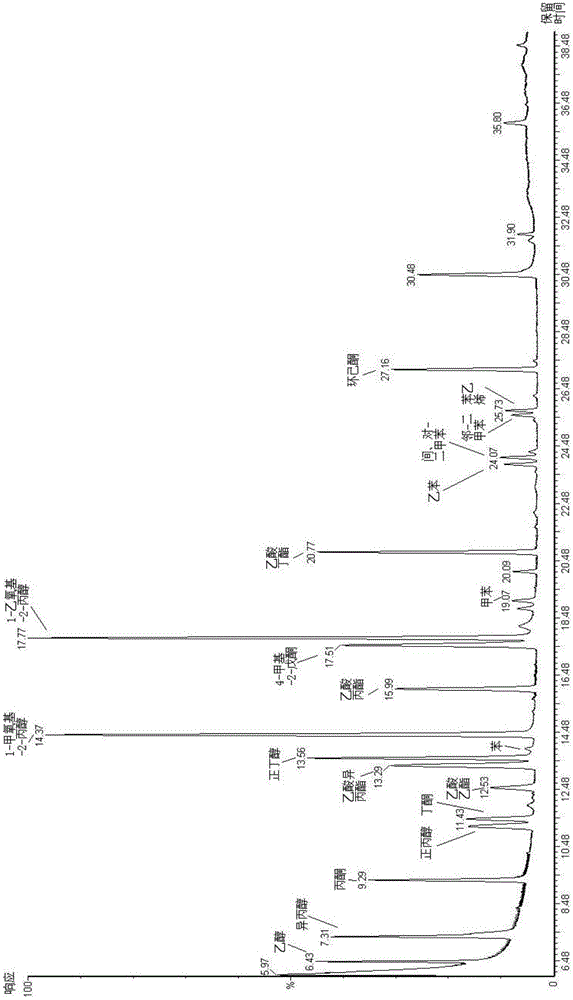

[0111] Example 1 Detection of special-shaped packaging materials for cigarettes

[0112] 1. Instruments and reagents

[0113] Detection instrument: PerkinElmer Clarus 600 gas chromatograph, PerkinElmer Clarus600MS detector, METTLER TOLEDO BT224S (sensitivity 0.1 mg).

[0114] Standard substances: benzene, toluene, ethylbenzene, xylene, styrene, ethanol, isopropanol, n-propanol, n-butanol, 1-methoxy-2-propanol, 1-ethoxy-2-propanol Alcohol, acetone, butanone, 4-methyl-2-pentanone, cyclohexanone, ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, all of analytical grade.

[0115] Extraction reagent: Methanol, analytically pure.

[0116] Internal standard stock solution: Weigh 0.105 g of 2-hexanone (analytically pure), dissolve it in 100 mL of methanol (analytical pure), and prepare a 1.05 mg / mL internal standard stock solution.

[0117] Internal standard solution: pipette 1 mL of internal standard stock solution into a 100 mL volumetric flask, dilute to the...

Embodiment 2

[0143] Embodiment 2 method detection limit

[0144] The qualitative detection limit when the signal-to-noise ratio (in full scan mode) is 3 is calculated by using the 4-level mixed standard solution (s4), and the qualitative detection limit when the signal-to-noise ratio (under the SIR mode) is 10 is calculated by using the 4-level mixed standard solution (s4) Quantitative detection limit. Qualitative and quantitative detection limit data are detailed in Table 2 above.

[0145] Drawn from Table 2, the qualitative detection limit of the inventive method is 0.021~0.441mg / L, and the quantitative detection limit is 0.006~0.229mg / L.

Embodiment 3

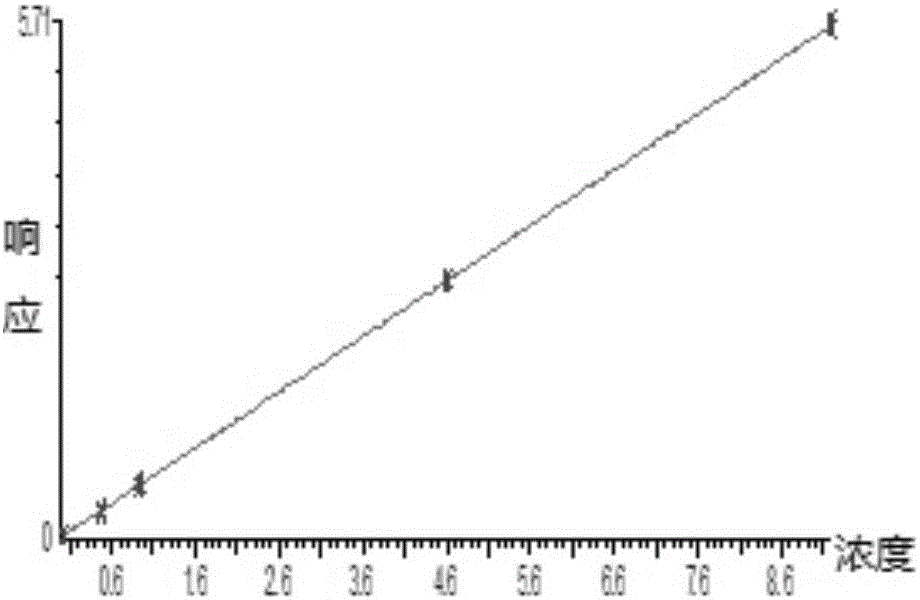

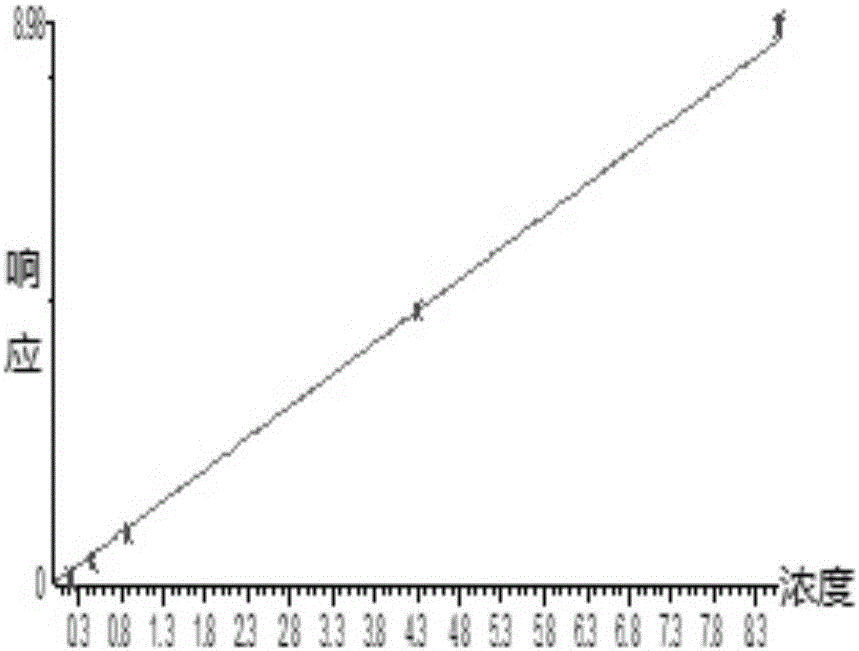

[0146] Embodiment 3 method linear correlation coefficient, repeatability and rate of recovery

[0147] Cut 40cm 2 (about 3g) No. 2 special-shaped packaging material for cigarettes in embodiment 1, accurately weighed to 0.0001g, add respectively the mixed standard solution of three kinds of concentrations of S1, S3, S5 and carry out method recovery rate test, calculate the recovery rate of each substance and the relative standard deviation (repeatability) between the measured values, the results are shown in Table 5.

[0148] table 5

[0149]

[0150] It can be concluded from Table 5 that the relative standard deviation of the measured values of the detection method of the present invention is 0.45-3.72%, all below 5%, and the repeatability is good. The recoveries were 80.80-119.83%, all between 80% and 120%, indicating that this method has a higher recovery rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com