Novel down pipe pyrolysis liquefying system in ceramic heat storage ball cyclic heating mode

A technology of circulating heating and heat storage balls, applied in the direction of direct heating dry distillation, special forms of dry distillation, preparation of liquid hydrocarbon mixtures, etc. and other problems, to achieve the effect of rapid pyrolysis continuous and stable operation, high liquefaction conversion efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

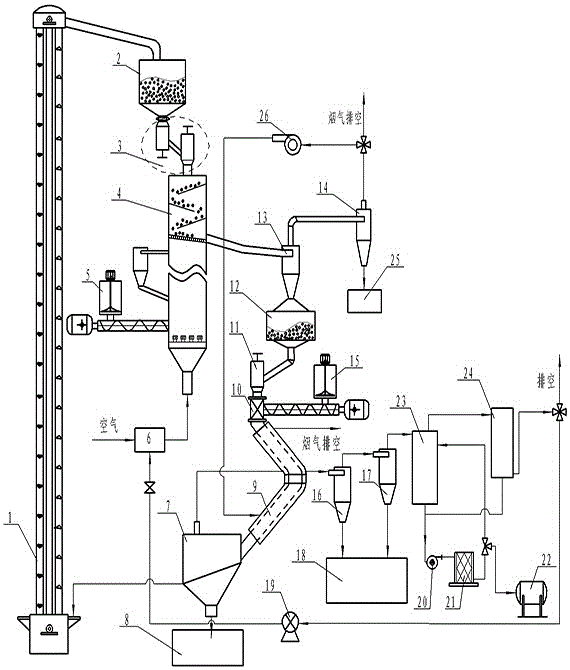

[0018] Such as figure 1 As shown, a new ceramic heat storage ball circulation heating type downcomer pyrolysis liquefaction system is characterized in that it includes a double-pipe heat carrier hoist 1 connected in sequence, a first heat carrier storage bin 2, a circulating fluidized bed type Heat carrier heater 4, gas-solid separator 13, second heat carrier storage bin 12, V-shaped casing reactor 9, heat carrier separator 7, wherein, the upper part of the double-pipe heat carrier hoist 1 and the first heat carrier The storage bin 2 is connected by a pipeline, the upper part of the circulating fluidized bed heat carrier heater 4 is connected with the gas-solid separator 13 by a pipeline, and the lower part is connected with the first biomass feeder 5 and the V-shaped casing reactor 9 The upper part is connected with a second biomass feeder 15, and the bottom of the heat carrier heater 4 is connected to the gas mixing controller 6 by pipelines; an H-type heat carrier flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com