Processing method of carbon fiber weaving fabric

A treatment method and carbon fiber technology, applied in fiber treatment, carbon fiber, physical treatment and other directions, can solve the problems of carbon fiber damage, inability to use carbon fiber fabric surface treatment, affecting the preparation of carbon fiber composite materials, etc., to achieve good microwave absorption performance, eliminate carbon fiber effects of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

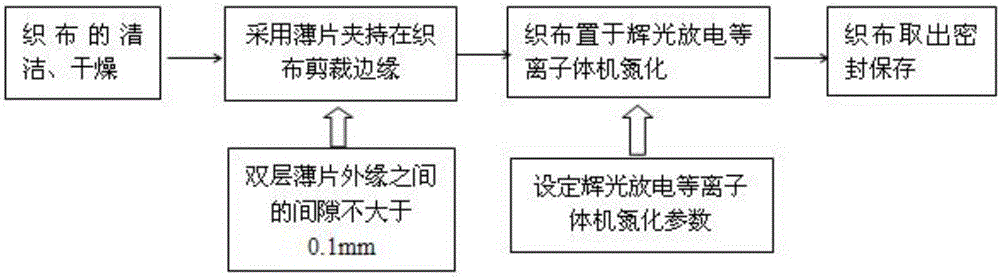

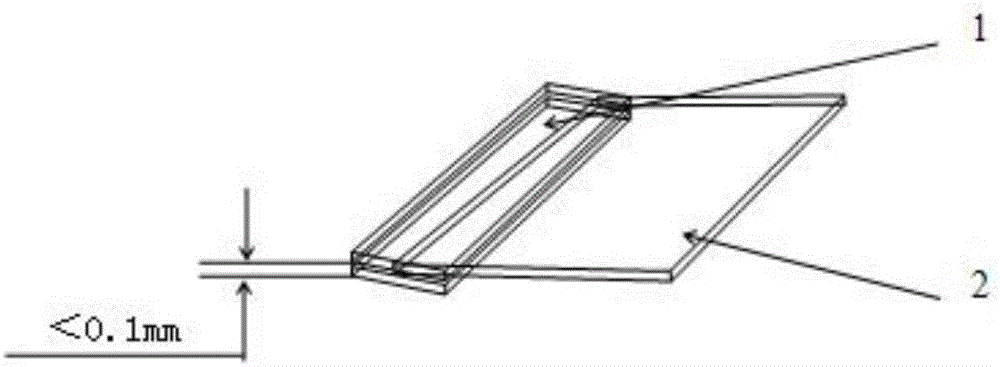

[0025] After the carbon fiber woven cloth is cleaned and dried, it is clamped on the cutting edge surface of the carbon fiber woven cloth with double-layer alloy steel sheets, and the gap between the outer edges of the double-layer sheets is not greater than 0.1mm. Arrange the clamped carbon fiber fabric into the glow plasma treatment machine and place it on the cathode workbench of the glow plasma treatment machine. Low-temperature and low-pressure nitrogen ion treatment is carried out at a temperature of 100° C., a treatment time of 120 minutes, and a treatment pressure of 200 Pa. The treated carbon fiber fabric is obtained.

[0026] A section of carbon fiber bundle in the carbon fiber woven cloth was taken to measure the resistivity value of 2.96Ω·cm, and the resistivity of untreated carbon fiber was 1.93Ω·cm. The influence of this change on the mechanical properties of the material was further analyzed. The carbon fiber plate is tested on a dynamic thermomechanical analyz...

Embodiment 2

[0028] After the carbon fiber woven cloth is cleaned and dried, it is clamped on the cutting edge surface of the carbon fiber woven cloth with double-layer diamond sheets, and the gap between the outer edges of the double-layer sheets is not greater than 0.1mm. Arrange the clamped carbon fiber fabric into the glow plasma treatment machine and place it on the cathode workbench of the glow plasma treatment machine. Low-temperature and low-pressure nitrogen ion treatment is carried out at a temperature of 300° C., a treatment time of 80 minutes, and a treatment pressure of 120 Pa. The treated carbon fiber fabric is obtained.

[0029] A section of carbon fiber bundle in the carbon fiber woven cloth was taken to measure the resistivity value of 3.74Ω·cm, and the influence of this change on the mechanical properties of the material was further analyzed. The carbon fiber plate is tested on a dynamic thermomechanical analyzer. The normal temperature glassy storage modulus of the carb...

Embodiment 3

[0031] After the carbon fiber woven cloth is cleaned and dried, it is clamped on the cutting edge surface of the carbon fiber woven cloth with double-layer diamond-like sheets, and the gap between the outer edges of the double-layer sheets is not greater than 0.1mm. Arrange the clamped carbon fiber fabric into the glow plasma treatment machine and place it on the cathode workbench of the glow plasma treatment machine. Low-temperature and low-pressure nitrogen ion treatment is carried out at a temperature of 500° C., a treatment time of 30 minutes, and a treatment pressure of 50 Pa. The treated carbon fiber fabric is obtained.

[0032] A section of carbon fiber bundle in the carbon fiber woven cloth was taken to measure the resistivity value of 3.48Ω·cm, and the influence of this change on the mechanical properties of the material was further analyzed. The carbon fiber plate is tested on a dynamic thermomechanical analyzer. The normal temperature glassy storage modulus of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity value | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com