Graphene oxide chiral polypyrrole hybrid material, anti-corrosion wave-absorbing coating and preparation method

A graphene, chiral technology, applied in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve problems such as reducing dispersion and impedance matching, achieve strong seawater corrosion resistance, excellent microwave absorption performance, improve The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

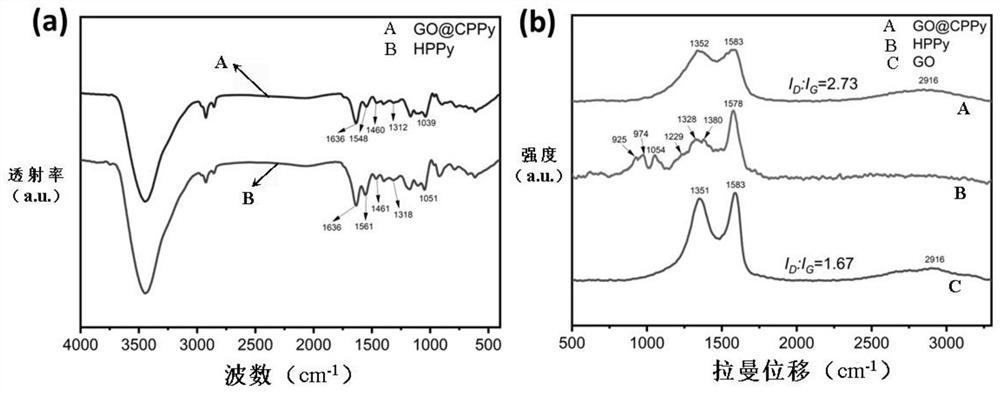

[0039] A preparation method of graphene oxide / chiral polypyrrole hybrid material, comprising the following steps:

[0040] Step 1: Add N-myristoyl-L-glutamic acid and pyrrole monomer into the solvent, and disperse fully and uniformly to obtain mixed solution A; the mass ratio of N-myristoyl-L-glutamic acid and pyrrole monomer It is 1:3~5; The preparation method of N-myristoyl-L-glutamic acid is as follows:

[0041] S11: Add L-glutamic acid and sodium hydroxide to the solvent, stir and mix well; the concentration of sodium hydroxide in the solution formed in S11 is 5-6g / mL, and the concentration of sodium hydroxide in S12 is 0.001mol / mL mL; the molar ratio of L-glutamic acid in S11 to N-myristoyl chloride in S12 was 1:1.

[0042] S12: Add dropwise an aqueous solution of N-myristoyl chloride and sodium hydroxide to the solution obtained in step S11, and stir thoroughly;

[0043] S13: After fully reacting, the pH value was adjusted to 1 under ice bath conditions, and white crys...

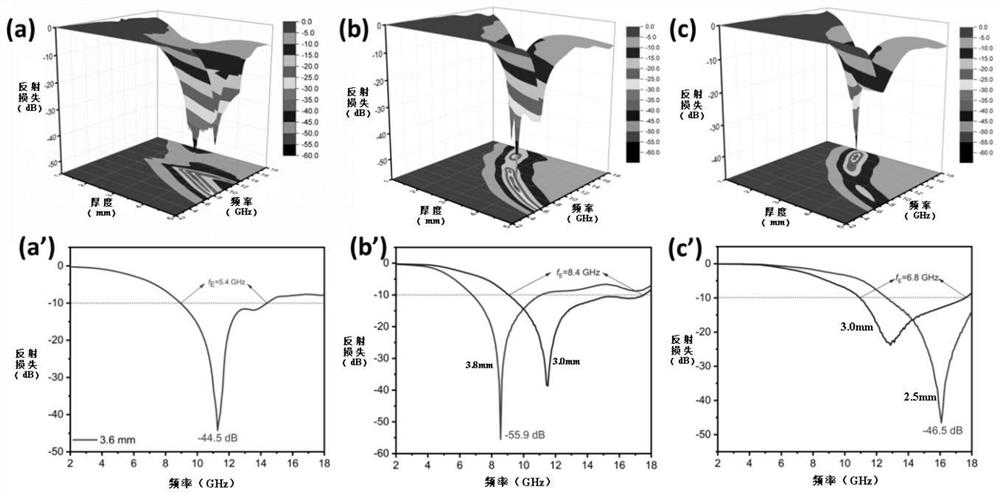

Embodiment 1

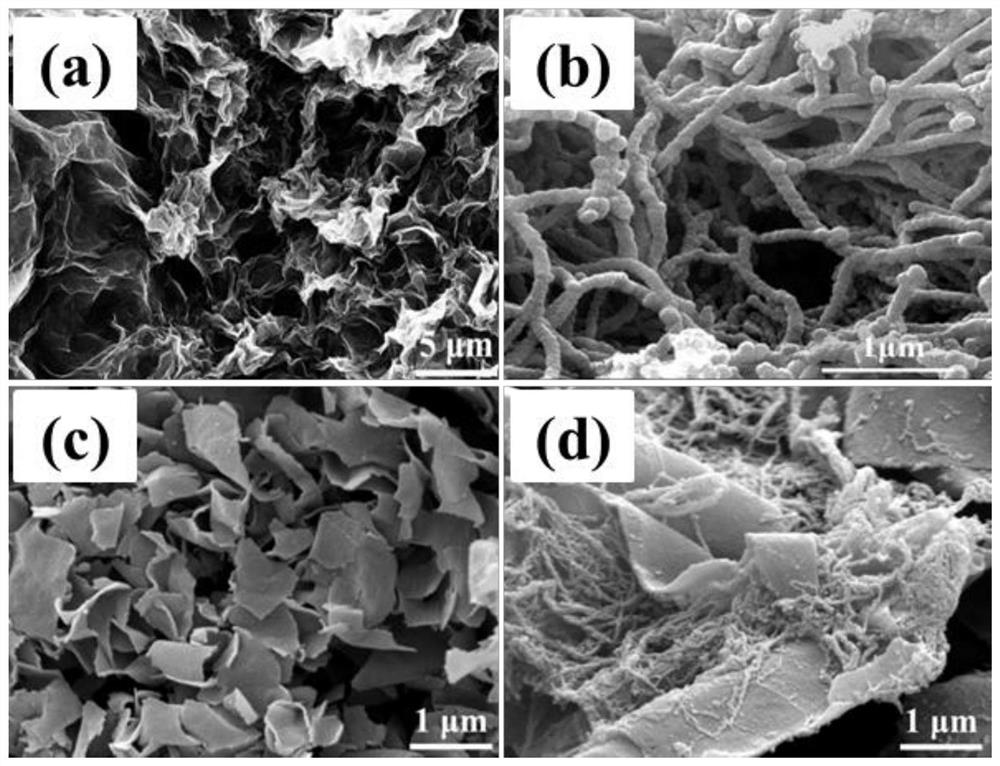

[0054] Graphene oxide / chiral polypyrrole hybrid materials were prepared according to the following steps:

[0055] Step 1: Add 30 mg of N-myristoyl-L-glutamic acid and 2 mmol of distilled and purified pyrrole monomer (Py) into 15 mL of absolute ethanol at room temperature, and sonicate at 100 W for 30 min.

[0056] The preparation method of N-myristoyl-L-glutamic acid is as follows:

[0057] S11: At room temperature, add L-glutamic acid and sodium hydroxide to the acetone solution, and stir mechanically for 30 minutes to mix the system evenly; the concentration of L-glutamic acid in the mixed solution is 0.001mol / mL, The sodium concentration was 5-6 g / mL.

[0058] S12: Add an aqueous solution of N-myristoyl chloride and sodium hydroxide dropwise to the solution obtained in step S11, with mechanical stirring during the dropwise addition to make the system fully react. After the dropwise addition, the concentration of N-myristoyl chloride in the solution was 0.001 mol / mL, and th...

Embodiment 2

[0065] Graphene oxide / chiral polypyrrole hybrid materials were prepared according to the following steps:

[0066] Step 1: Add 30 mg of N-myristoyl-L-glutamic acid and 5 mmol of distilled and purified pyrrole monomer (Py) into 15 mL of absolute ethanol at room temperature, and sonicate at 100 W for 30 min.

[0067] The preparation method of N-myristoyl-L-glutamic acid is as follows:

[0068] S11: At room temperature, add L-glutamic acid and sodium hydroxide to the acetone solution, and stir mechanically for 30 minutes to mix the system evenly; the concentration of L-glutamic acid in the mixed solution is 0.001mol / mL, The sodium concentration was 5-6 g / mL.

[0069] S12: Add an aqueous solution of N-myristoyl chloride and sodium hydroxide dropwise to the solution obtained in step S11, with mechanical stirring during the dropwise addition to make the system fully react. After the dropwise addition, the concentration of N-myristoyl chloride in the solution was 0.001 mol / mL, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com