A kind of preparation technology of toughened glass covered with copper-based composite coating on the surface

A preparation process, copper-based composite technology, applied in the direction of coating, etc., can solve the problems of low service life, low production and sales rate, low coating hardness, etc., and achieve the effect of strong wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

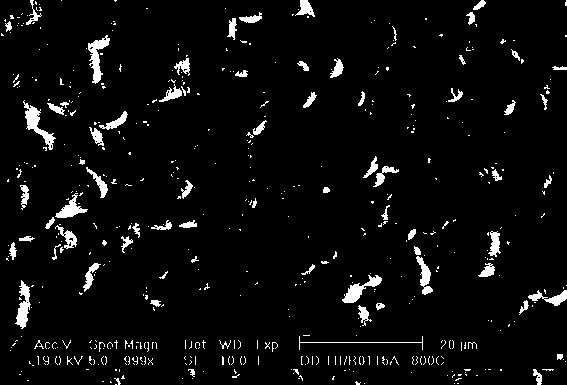

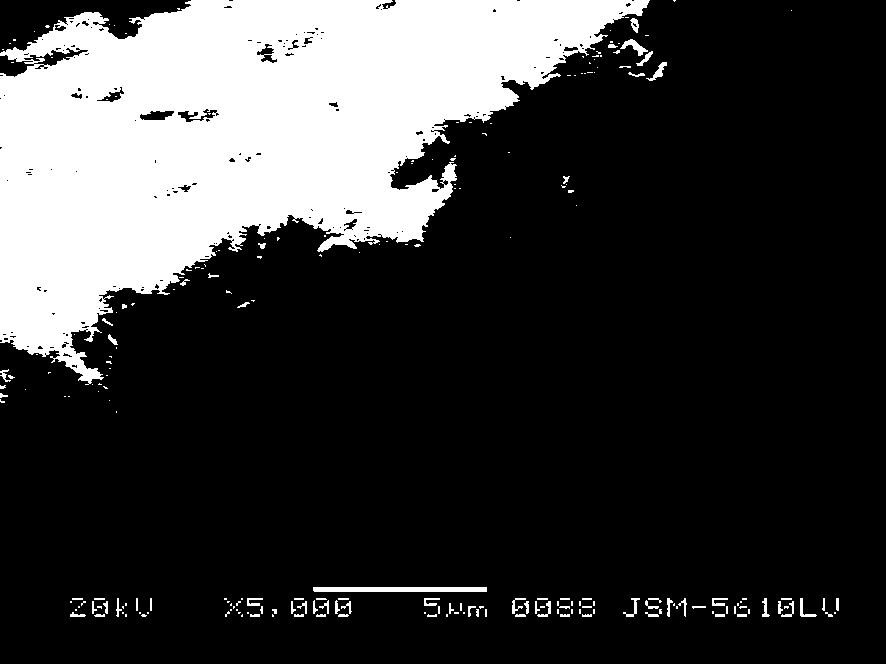

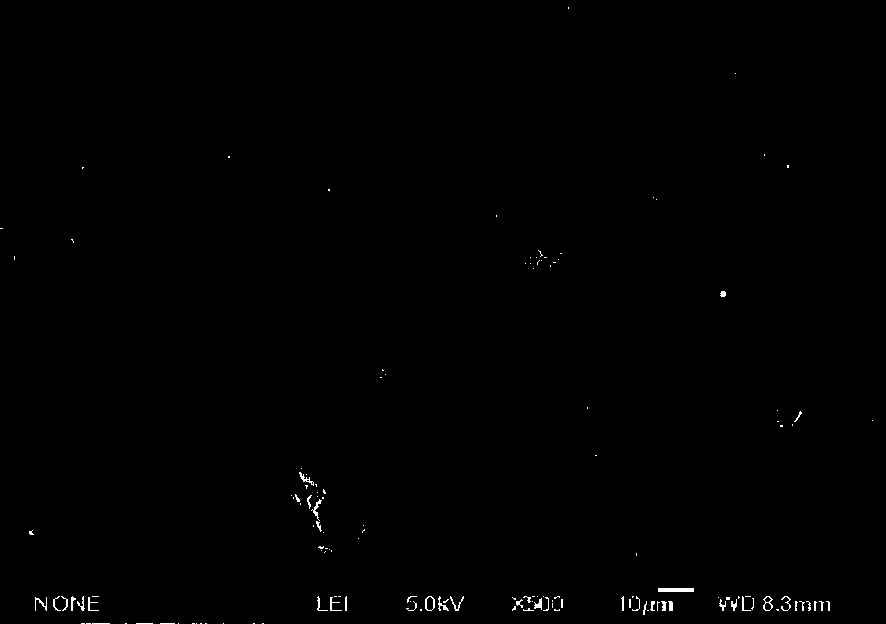

Image

Examples

Embodiment 1

[0032] (1) Weigh boric acid, vanadium pentoxide, zinc oxide, silicon dioxide, titanium dioxide, and bismuth trioxide according to the mass ratio of 18:8:5:9:4:56 and pour them into the corundum ball milling altar. The diameter is 600mm, and corundum balls are added according to the mass ratio of ball to material 0.5:1, among which corundum balls with a diameter of 50mm account for 30%, and corundum balls with a diameter of less than 50mm account for 70%. The rotation speed of the ball mill is 30r / min. The raw material was ball milled for 1.5 hours and then taken out to obtain the raw material for smelting glass base material.

[0033] (2) Heat the crucible furnace to 1100°C at a speed of 4°C / min, plug the plugging rod, and pour in the powder mixed in step (1), the volume of the powder poured in is 4 / 5 of the volume of the crucible , Put an enamel container filled with water at the outlet of the crucible furnace. When the furnace temperature rises to 1100°C again, keep the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com