Preparation method of hydrophilic latex-agglomerated anion chromatographic packing

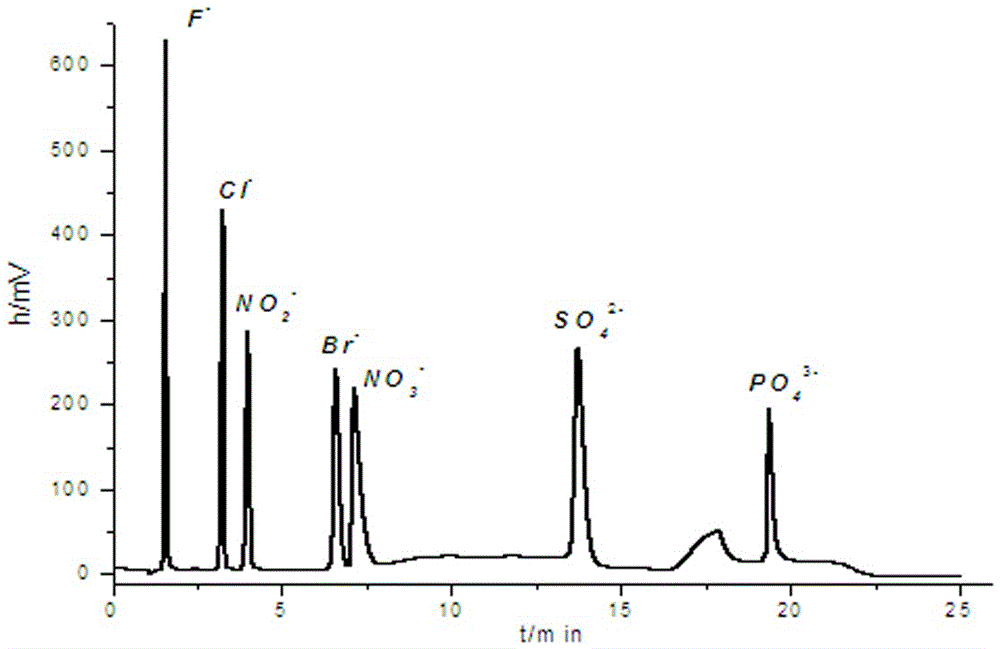

An anion chromatography and hydrophilic technology, applied in the field of preparation of hydrophilic latex agglomeration type anion chromatography packing, can solve the problem that fluoride ion and water negative peak cannot be completely separated, the detection result is inaccurate, and the peaks of seven kinds of ion chromatography can be solved. Poor shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

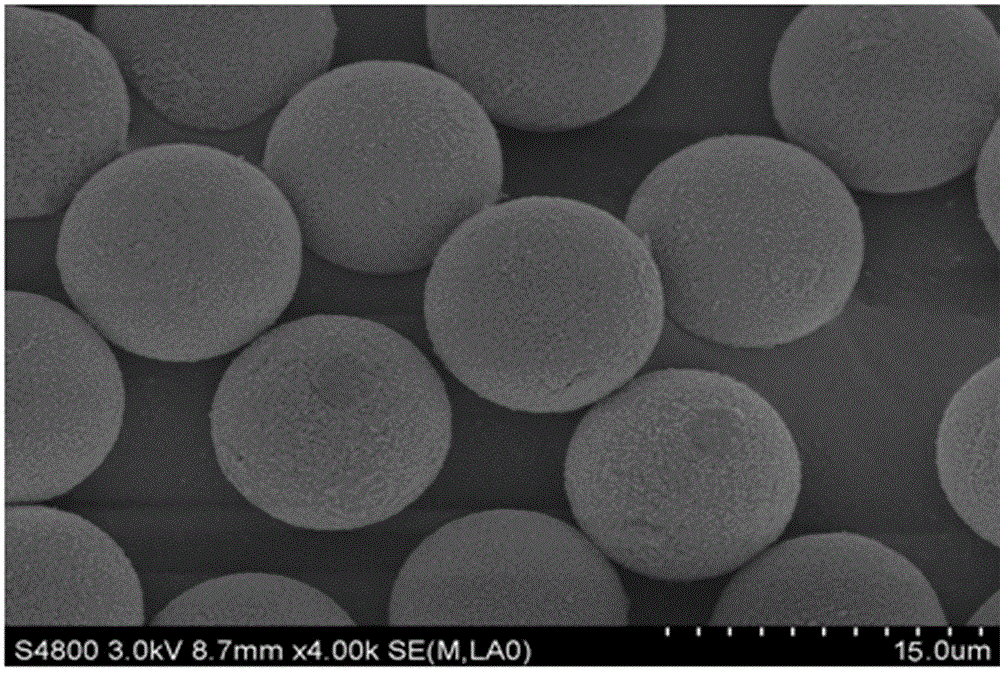

[0027] Step 1, preparation of sulfonated polystyrene-divinylbenzene copolymer skeleton microspheres

[0028] Select polystyrene-divinylbenzene copolymer microspheres with a particle size of 5 μm and a crosslinking degree of 5% prepared by suspension polymerization, and wash them with hot water. Select 3 g dry weight of polystyrene-divinylbenzene copolymer microspheres washed with hot water, add 100 mL of concentrated sulfuric acid into a three-necked flask, raise the temperature to 50 ° C, and keep the reaction for 60 min. After the sulfonation reaction, close the water bath, slowly add 100mL 50% sulfuric acid from the dropping funnel, transfer the solution to deionized water after stirring, let it settle, and finally pour off the upper layer, and suction filter to obtain sulfonated polyphenyl Ethylene-divinylbenzene copolymer skeleton microspheres.

[0029] Step 2, microemulsion polymerization synthesis of polyglycidyl methacrylate-ethylene glycol dimethacrylate nano-spheric...

Embodiment 2

[0039] Step 1, preparation of sulfonated polyvinylstyrene-divinylbenzene copolymer skeleton microspheres

[0040] The difference from Step 1 of Example 1 is: select polyvinylstyrene-divinylbenzene copolymer microspheres with a particle size of 30 μm and a crosslinking degree of 15%. Add 100mL of concentrated sulfuric acid into the three-necked flask, raise the temperature to 90°C, and keep the reaction for 25min. The sulfonated polyvinylstyrene-divinylbenzene copolymer skeleton microspheres were prepared by suction filtration.

[0041] Step 2, microemulsion polymerization synthesis of polyglycidyl methacrylate-ethylene glycol dimethacrylate nano-spherical latex

[0042] The difference from step 2 of Example 1 is: 6.32g (water phase mass 5.00%) sodium dodecylbenzenesulfonate; warm up to 65°C, add 18mL of persulfuric acid that dissolves 0.5g of potassium persulfate in 30mL of deionized water in advance Potassium solution, the stirring speed is 200r / min, heat preservation react...

Embodiment 3

[0051] Step 1, preparation of sulfonated polystyrene-divinylbenzene copolymer skeleton microspheres

[0052] The difference from Step 1 of Example 1 is: select polystyrene-divinylbenzene copolymer microspheres with a particle size of 10 μm and a crosslinking degree of 8%; add 100 mL of concentrated sulfuric acid into a three-necked flask, raise the temperature to 65° C., and keep the reaction for 50 minutes.

[0053] Step 2, microemulsion polymerization synthesis of polyglycidyl methacrylate-ethylene glycol dimethacrylate nano-spherical latex

[0054] The difference from step 2 of Example 1 is: 0.36g (water phase mass 0.30%) sodium dodecylbenzenesulfonate; be warmed up to 50°C, add 15mL of potassium persulfate solution dissolved in deionized water in advance, and the stirring speed is 80r / min, keep warm for 3.5h, then add the remaining 15mL potassium persulfate solution, keep warm for 4.0h and then cool to room temperature. Synthesize polyglycidyl methacrylate-ethylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com