Method for preparing honeycomb silk fibroin porous microsphere sustained drug release vector

A technology of silk fibroin and porous microspheres, which is used in drug combinations, pharmaceutical formulations, medical preparations containing active ingredients, etc., to achieve the effects of good biocompatibility, excellent biocompatibility, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the preparation method of the honeycomb silk fibroin porous microsphere drug slow-release carrier includes the following steps in turn:

[0037] (1) dissolving the fibrous silk fibroin formed after silkworm cocoon degumming, and obtaining an aqueous silk fibroin protein solution after filtration, dialysis, and concentration;

[0038] (2) Adjust the concentration of the silk fibroin solution in step (1) to 0.1 mg / mL and disperse it by ultrasound, put it into a dialysis bag and soak it in different times of human simulated body fluid. : 100 rpm.

[0039] (3) The shaker treatment time is 14 days, and the simulated body fluid in step (2) is replaced every 24 hours to obtain the microsphere suspension;

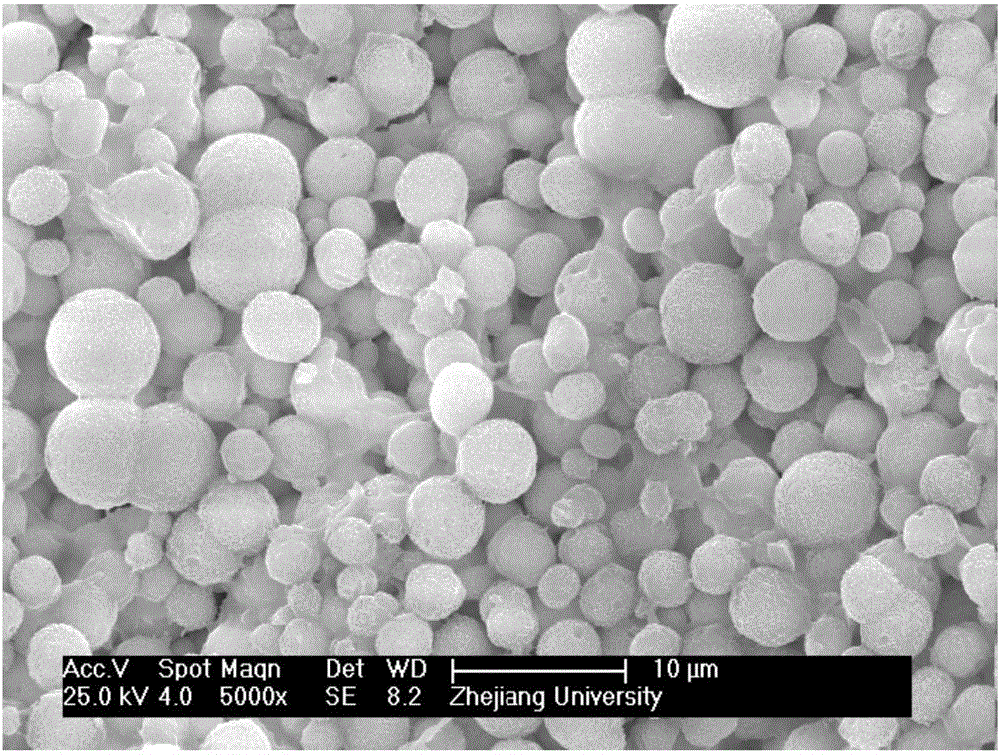

[0040] (4) The microsphere suspension in step (3) was washed several times with deionized water and absolute ethanol, centrifuged, and freeze-dried for 5 hours to obtain apatite / silk fibroin microspheres with a diameter of 1-5 μm. ;

[0041] (7) The bi...

Embodiment 2

[0043] The biomineralization method of the tussah silk fibroin that promotes cell growth in the present embodiment comprises the following steps successively:

[0044] (1) dissolving the fibrous silk fibroin formed after silkworm cocoon degumming, and obtaining an aqueous silk fibroin protein solution after filtration, dialysis, and concentration;

[0045] (2) Adjust the concentration of the silk fibroin solution in step (1) to 50 mg / mL and disperse it by ultrasonic waves, put it into a dialysis bag and soak it in different times of human simulated body fluid, the solution temperature is 37°C, and the rotation speed is: 200 rpm.

[0046] (3) The shaker treatment time is 1 day, and the simulated body fluid in step (2) is replaced every 24 hours to obtain the microsphere suspension;

[0047] (4) The microsphere suspension in step (3) was washed several times with deionized water and absolute ethanol, centrifuged, and dried at 60°C for 10 hours to obtain apatite / silk fibroin mic...

Embodiment 3

[0053] The biomineralization method of the tussah silk fibroin that promotes cell growth in the present embodiment comprises the following steps successively:

[0054] (1) dissolving the fibrous silk fibroin formed after silkworm cocoon degumming, and obtaining an aqueous tussah silk fibroin protein solution after filtration, dialysis and concentration;

[0055] (2) Adjust the concentration of the tussah silk fibroin protein solution in step (1) to 2 mg / mL and disperse it ultrasonically, put it into a dialysis bag and soak it in 5 times the simulated body fluid of the human body, the solution temperature is 37 °C, and the rotation speed : 20 rpm.

[0056] (3) The shaker treatment time is 7 days, and the simulated body fluid in step (2) is replaced every 24 hours to obtain the microsphere suspension;

[0057] (4) The microsphere suspension in step (3) was washed several times with deionized water and absolute ethanol, centrifuged, and freeze-dried for 48 hours to obtain apatit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com