Method for producing composite porous material containing metal-carbon-nitrogen

A technology of porous materials and metals, applied in the field of energy material preparation, can solve the problems of difficult preparation of sulfur cathode and poor conductivity of sulfur, and achieve the effect of being beneficial to electrochemical reaction, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, first dissolve 0.734g of zinc nitrate hexahydrate in 50mL of methanol, and dissolve 0.811g of 2-methylimidazole in 50mL of methanol.

[0038] In step 2, the above two solutions were mixed together and stirred evenly, and reacted at a room temperature of 25 degrees Celsius for 24 hours. The finished product ZnCN-1 was obtained by separation, washing and drying.

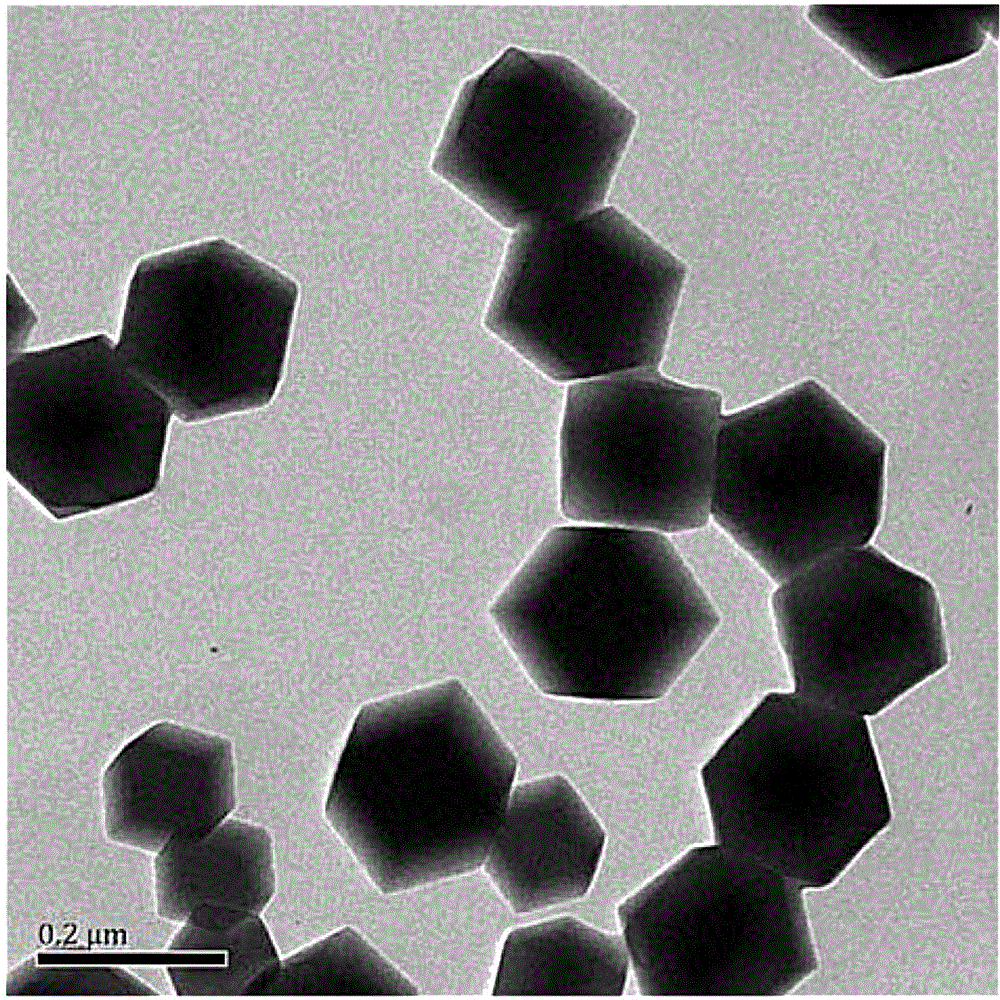

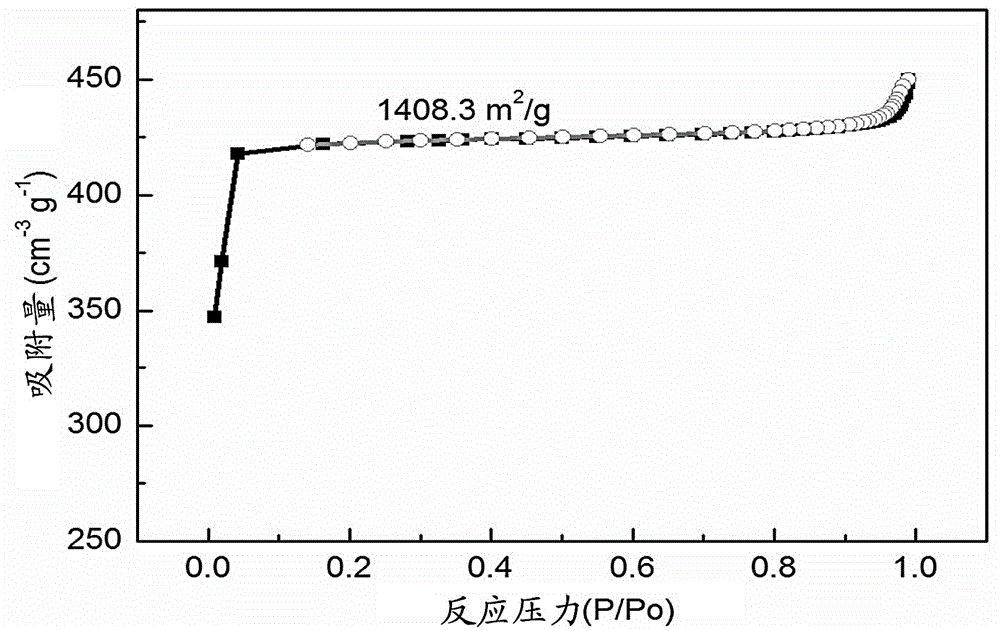

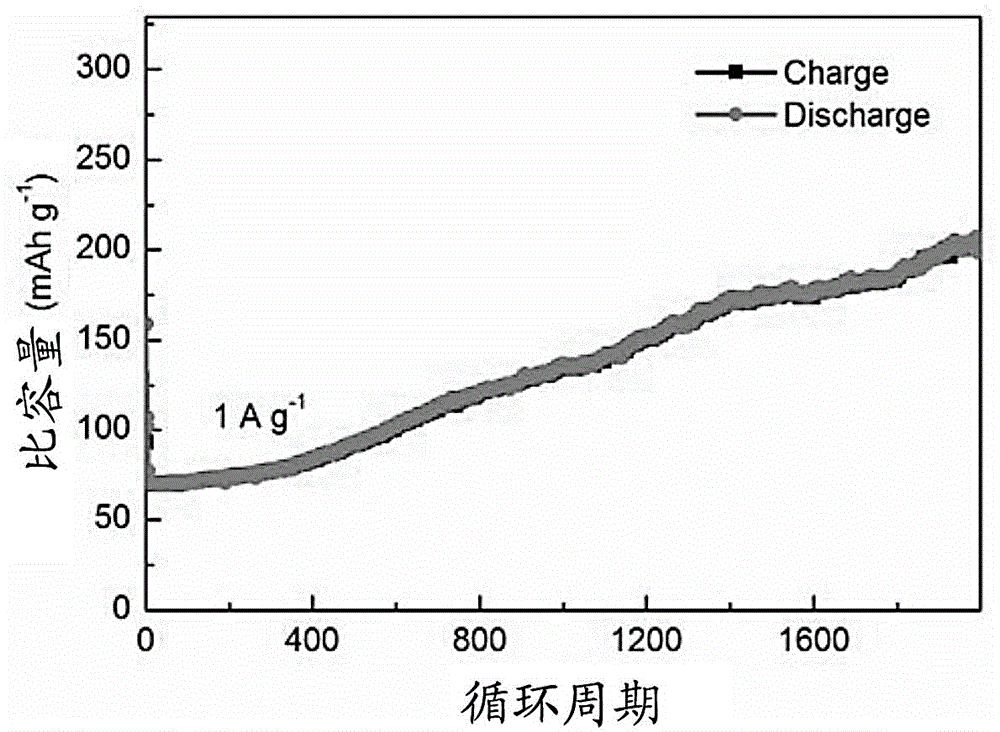

[0039] Such as figure 1 Shown, the transmission electron microscope characterization of gained product ZnCN-1; figure 2 The nitrogen gas adsorption-desorption isotherm diagram of ZnCN-1 at 77K is shown. Such as image 3 As shown, as a lithium-ion battery material, it can be cycled for 2000 cycles at a current of 1A / g.

Embodiment 2

[0041] Step 1, 2.938g of zinc nitrate hexahydrate was dissolved in 100mL of methanol, and 3.242g of 2-methylimidazole was dissolved in 100mL of methanol.

[0042] In step 2, the above two solutions were mixed together and stirred evenly, and reacted at a room temperature of 25 degrees Celsius for 24 hours. Separate, wash and dry to obtain the precursor.

[0043] Step 3: Pyrolysis at 700°C for 2 hours under a nitrogen atmosphere to obtain the finished product ZnCN-2.

[0044] Such as Figure 4Shown, the SEM characterization of the obtained ZnCN-2 product. Such as Figure 5 Shown, ZnCN-2 is used as the charge-discharge curve of the sodium-ion battery at 50mA / g current. Such as Figure 6 As shown, ZnCN-2 is used as a lithium-ion battery material under the charge-discharge curve of 200mA / g current at -10 degrees Celsius.

Embodiment 3

[0046] Step 1, 4.656g of cobalt nitrate hexahydrate was dissolved in 100mL of methanol, and 5.254g of 2-methylimidazole was dissolved in 100mL of methanol.

[0047] In step 2, the above two solutions were mixed together and stirred evenly, and reacted at a room temperature of 25 degrees Celsius for 24 hours. The finished product CoCN-1 was obtained by separation, washing and drying.

[0048] Such as Figure 7 As shown, the charge-discharge curve of CoCN-1 as a lithium-ion battery material at a current of 50mA / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com