Gallium nitride-based light emitting diode and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the effective barrier height of the electron blocking layer, reducing the blocking ability of the electron blocking layer, and increasing the effective barrier of the valence band, etc. , to improve the electron blocking ability, weaken the energy band bending effect, and improve the droop effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a gallium nitride-based LED with high light efficiency and a preparation method thereof. The preparation process mainly includes the following steps:

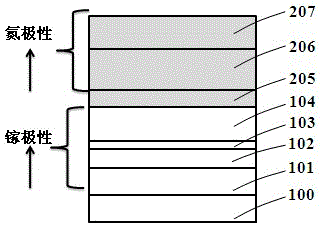

[0037] attached image 3 A high-efficiency gallium nitride-based LED prepared by the present invention is illustrated, which are as follows from bottom to top: substrate 100, gallium polar low-temperature buffer layer 101, gallium polar non-doped nitride layer 102, gallium polar N-type Nitride layer 103 , gallium polar multiple quantum well light emitting layer 104 , nitrogen polar electron blocking layer 205 , nitrogen polar P-type nitride layer 206 , nitrogen polar P-type nitride contact layer 207 .

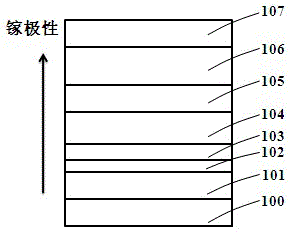

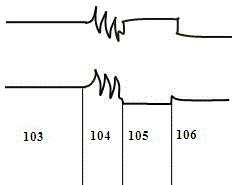

[0038] Figure 4 The energy band structure diagram of the above-mentioned high-efficiency GaN-based LED is shown. and figure 2 Compared with the energy band structure diagram of the conventional commercial gallium polar gallium nitride-based LED shown, in the above structure, the polarized charg...

Embodiment 2

[0050] This embodiment is different from Embodiment 1 in that: the P-type nitride layer and the P-type nitride contact layer are Ga polar. Using gallium-polarity P-type nitride layer and P-type nitride contact layer behind the nitrogen-polarity electron blocking layer can make the surface of the device smoother, which is beneficial to the electrode preparation of the subsequent chip process, such as Figure 5 .

[0051] In this embodiment, the gallium polar low temperature buffer layer 101, the gallium polar non-doped nitride layer 102, the gallium polar N-type nitride layer 103, the gallium polar multilayer After the quantum well light-emitting layer 104, the substrate is transferred to a molecular beam epitaxy reaction chamber to grow a nitrogen polar electron blocking layer 205, a gallium polar P-type nitride layer 306 and a gallium polar P-type nitride contact layer 307. Wherein the nitrogen-polar electron blocking layer 205 is grown under nitrogen-rich conditions, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com