Method for preparing high-elasticity high-absorbency hemostatic and bacteriostatic expansive sponge

A high-elasticity, sponge technology, applied in the field of polyvinyl acetalized expansion sponge in many fields, can solve the problems of reducing water absorption and softness of materials, increasing wound infection, uneven cells, etc., and achieves excellent biocompatibility Effects of sex and cell affinity, reduced interference with surgery, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

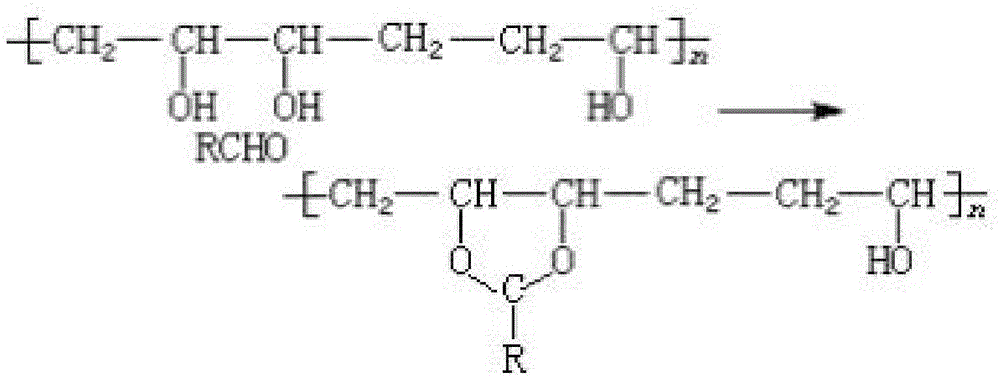

Method used

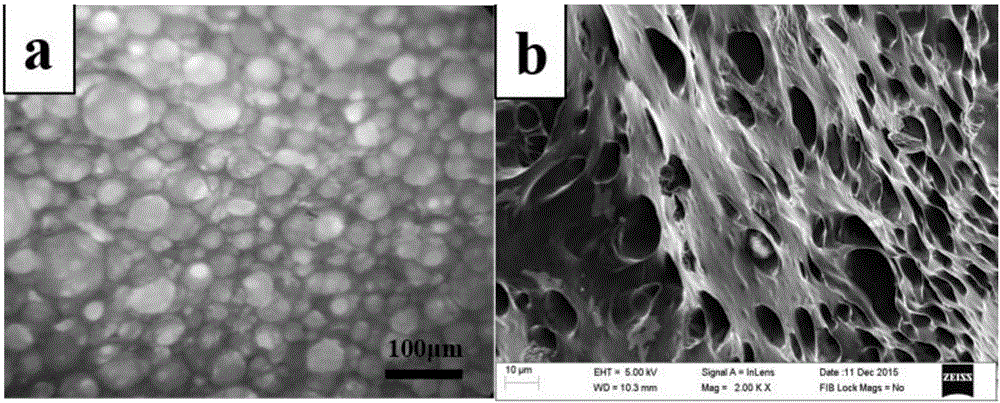

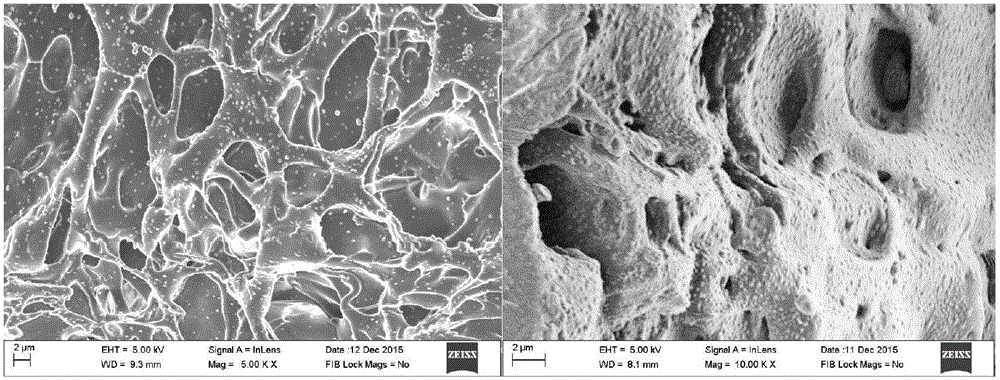

Image

Examples

Embodiment 1

[0054] Step 1: remove a certain amount of PVA, and add a certain amount of deionized water according to the requirement that the mass ratio of PVA to deionized water is 1:5. Heat and stir in a water bath at 95°C for 1 hour to fully dissolve the PVA particles. Adjust the temperature of the constant temperature water bath to 60°C, weigh the sodium alginate according to the mass ratio of polyvinyl alcohol to sodium alginate as 1:0.2, add it to the above polyvinyl alcohol solution, continue to stir until the sodium alginate dissolves evenly, and let stand 0.5h, remove air bubbles and keep warm.

[0055] Step 2: Add the mixed solution of surfactant and catalyst to the mixed solution of polyvinyl alcohol sodium alginate, and stir at a low speed for 2 to 5 minutes, so that the surfactant and catalyst can be uniformly dispersed in the solution, so that the surfactant and catalyst can be uniformly dispersed. dispersed into the solution.

[0056] Step 3: Weigh the formaldehyde solutio...

Embodiment 2

[0060] Step 1. Remove a certain amount of PVA, and add a certain amount of deionized water according to the requirement that the mass ratio of PVA to deionized water is 1:7. Heat and stir in a water bath at 95°C for 1 hour to fully dissolve the PVA particles. Adjust the temperature of the constant temperature water bath to 60°C, weigh the sodium alginate according to the mass ratio of polyvinyl alcohol to sodium alginate as 1:0.6, add it to the above polyvinyl alcohol solution, continue to stir until the sodium alginate dissolves evenly, and let stand 0.5h, remove air bubbles and keep warm.

[0061] Step 2: Add the mixed solution of surfactant and catalyst into the mixed solution of polyvinyl alcohol sodium alginate, and stir at a low speed for 2-5 minutes, so that the surfactant and catalyst can be uniformly dispersed in the solution.

[0062] Step 3. Weigh the glutaraldehyde solution according to the mass ratio of polyvinyl alcohol and glutaraldehyde solution as 1:1.5, add ...

Embodiment 3

[0065] Step 1: remove a certain amount of PVA, and add a certain amount of deionized water according to the requirement that the mass ratio of PVA to deionized water is 1:8. Heat and stir in a water bath at 95°C for 1 hour to fully dissolve the PVA particles. Adjust the temperature of the constant temperature water bath to 60°C, weigh the sodium alginate according to the mass ratio of polyvinyl alcohol to sodium alginate as 1:1, add it to the above polyvinyl alcohol solution, continue to stir until the sodium alginate dissolves evenly, and let stand 0.5h, remove air bubbles and keep warm.

[0066] Step 2: Add the mixed solution of surfactant and catalyst into the mixed solution of polyvinyl alcohol sodium alginate, and stir at a low speed for 2-5 minutes, so that the surfactant and catalyst can be uniformly dispersed in the solution.

[0067] Step 3: Weigh the fatty aldehyde solution according to the mass ratio of polyvinyl alcohol and fatty aldehyde to 1:1, add it into the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com