a kind of coal 2 o 4 Nano powder, preparation method and application

A nano-powder and coal2o4 technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of cumbersome synthesis of cobalt blue pigments, etc., and achieve the effect of fewer types of equipment, high purity, and fewer types of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034](1) Disperse 1.5g of halloysite in 60mL of absolute ethanol, stir ultrasonically for 30min, then add 2.328g of Co(NO 3 ) 2 ·6H 2 0, obtain the suspension after ultrasonic stirring for 30min mixing;

[0035] (2) Weigh 6.56g of 2-methylimidazole and dissolve it in 60mL of absolute ethanol to obtain a solution. Slowly add 60mL of the solution to the 60mL suspension prepared in step (1), and after ultrasonic stirring for 30min, continue to Place and age for 24h to obtain a layered mixed solution;

[0036] (3) Suction filter the layered mixture to obtain a solid phase, rinse the solid phase with absolute ethanol and deionized water 4 times, dry it in vacuum at 60°C for 16 hours, grind to obtain a purple powder, take 0.3 g of the purple powder and place it in a tube Calcination was carried out at 900°C in a type furnace, the heating rate was 2°C / min, and the holding time was 2h, to obtain blue CoAl 2 o 4 Nano powder.

Embodiment 2

[0038] (1) Disperse 1.5g of halloysite in 60mL of absolute ethanol, stir ultrasonically for 30min, then add 2.328g of Co(NO 3 ) 2 ·6H 2 0, obtain the suspension after ultrasonic stirring for 30min mixing;

[0039] (2) Weigh 6.56g of 2-methylimidazole and dissolve it in 60mL of absolute ethanol to obtain a solution; slowly add 60mL of the solution to the 60mL suspension prepared in step (1), and after ultrasonic stirring for 30min, continue to Place and age for 24h to obtain a layered mixed solution;

[0040] (3) Suction filter the layered mixture to obtain a solid phase, wash the solid phase with absolute ethanol and deionized water 4 times, dry it in vacuum at 60°C for 15 hours, grind to obtain a purple powder, take 0.3 g of the purple powder and put it in a tube Calcined at 800°C in a type furnace, the heating rate was 2°C / min, and the holding time was 2h, to obtain blue CoAl 2 o 4 Nano powder;

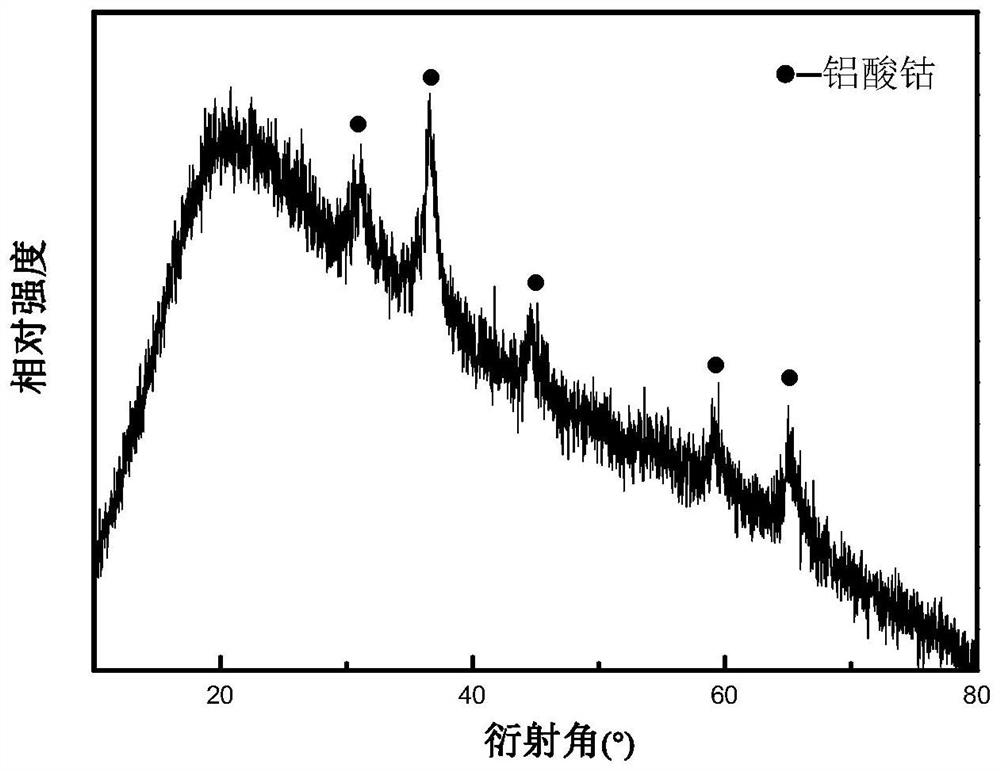

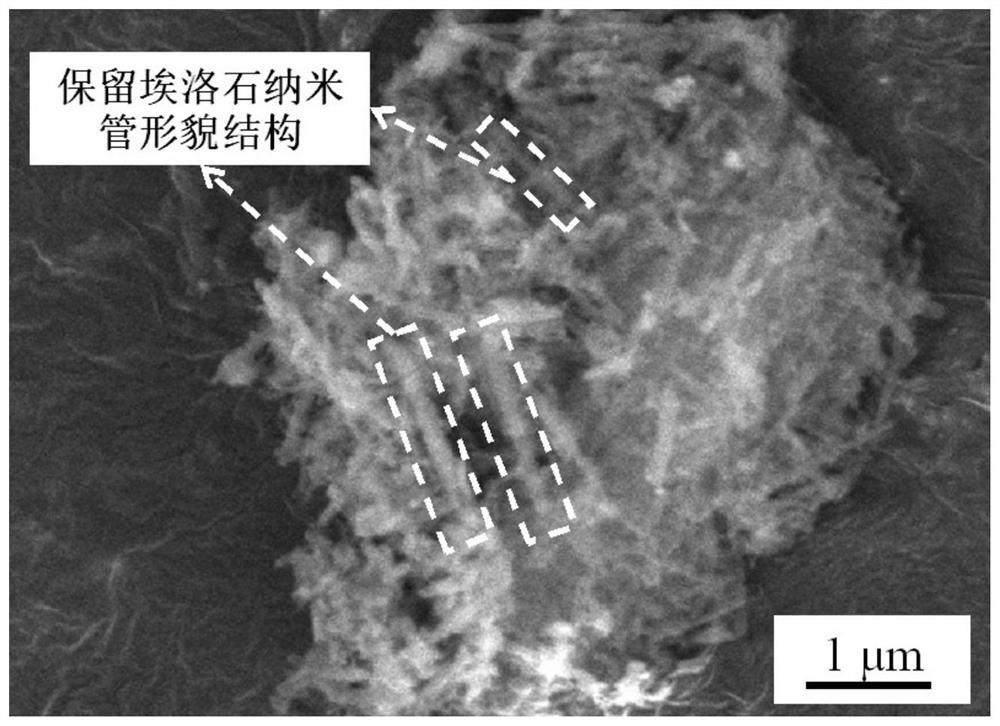

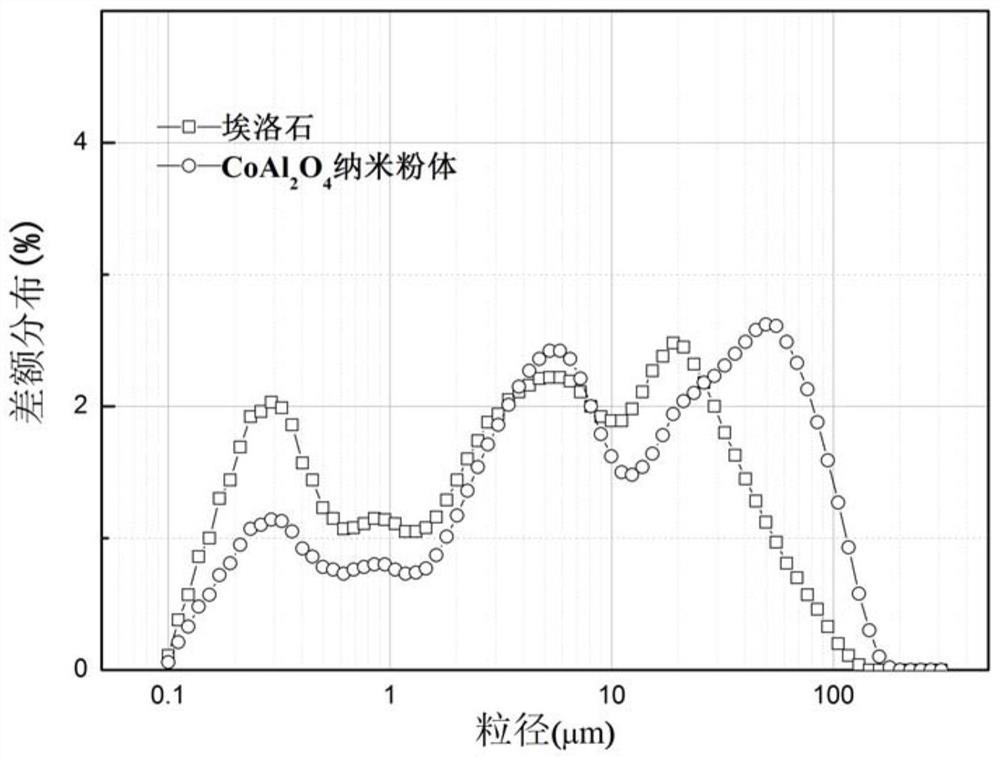

[0041] The CoAl 2 o 4 XRD pattern of nano powder figure 1 As shown, th...

Embodiment 3

[0045] (1) Disperse 1.4g of halloysite in 60mL of absolute ethanol, stir ultrasonically for 30min, then add 2.328g of Co(NO 3 ) 2 ·6H 2 0, obtain the suspension after ultrasonic stirring for 30min mixing;

[0046] (2) Weigh 6.816g of 2-methylimidazole and dissolve it in 60mL of absolute ethanol to obtain a solution; slowly add 60mL of the solution to the 60mL suspension obtained in step (1), stir ultrasonically for 30min, and then continue to stand Aging for 22h to obtain a stratified mixed solution;

[0047] (3) Suction filter the layered mixture to obtain a solid phase, wash the solid phase with absolute ethanol and deionized water 4 times, dry it in vacuum at 60°C for 18 hours, grind to obtain a purple powder, take 0.3 g of the purple powder and place it in a tube Calcination was carried out at 900°C in a type furnace, the heating rate was 2°C / min, and the holding time was 2h, to obtain blue CoAl 2 o 4 Nano powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com