Composite metal foil, composite metal foil with carrier, metal-clad laminate obtained using said composite metal foil or said composite metal foil with carrier, and printed wiring board

A technology for metal-clad laminates and printed circuit boards, used in printed circuits, printed circuit manufacturing, metal layered products, etc., can solve the problems of micro-cracks, lack of flexibility, etc., and achieve the effect of good signal transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

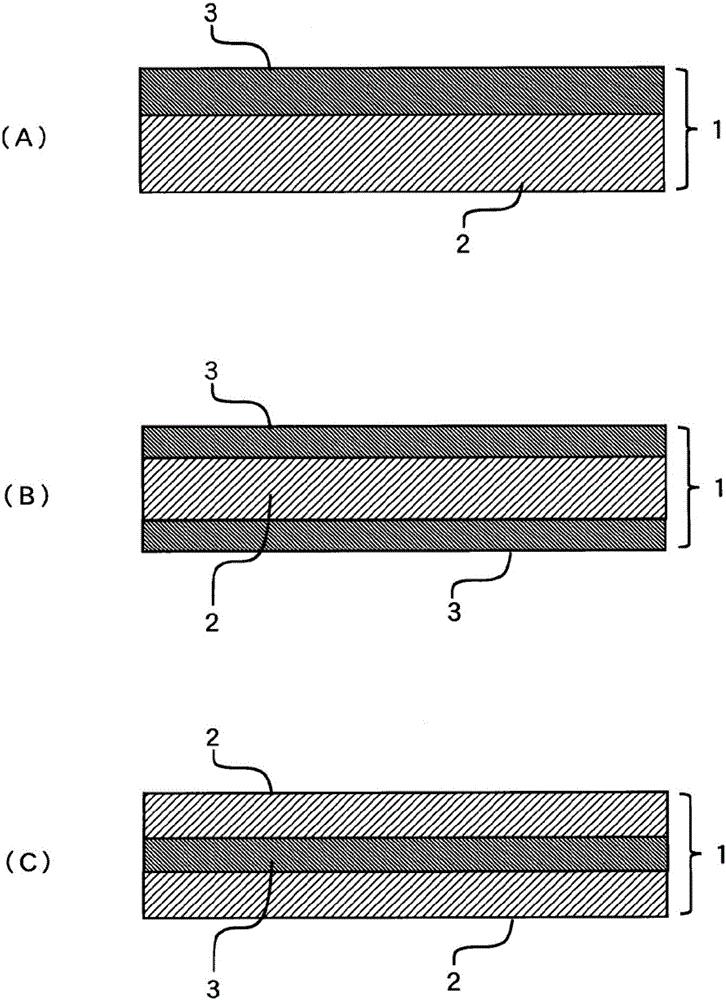

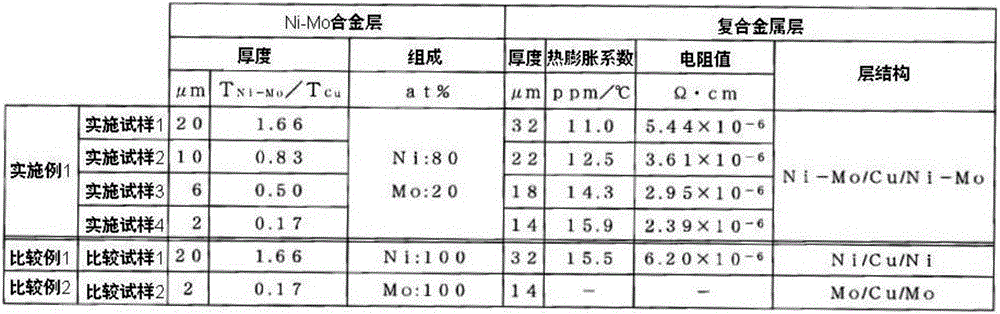

[0073] In embodiment 1, with untreated copper foil (thickness T Cu 12μm electrolytic copper foil), after electroplating the nickel-molybdenum alloy with the thickness shown in Table 1 on both sides (the total thickness of both sides), the obtained figure 1 The layer structure of "nickel-molybdenum alloy layer 3 / copper layer 2 / nickel-molybdenum alloy layer 3" shown in (B), 4 kinds of composite metal foils 1 with equal thickness of the nickel-molybdenum alloy plating layer on both sides (implementation test) Sample 1 to implement sample 4). The nickel-molybdenum alloy plating solution and plating conditions at this time are as follows.

[0074] (nickel-molybdenum alloy plating solution and plating conditions)

[0075] Nickel sulfate hexahydrate: 40g / L

[0076] Sodium molybdate 2 hydrate: 25g / L

[0077] 3 sodium citrate: 80g / L

[0078] Solution pH: 9

[0079] Current density: 16A / dm 2

[0080] Anode electrode: insoluble anode

[0081] Then, the thermal expansion coeffici...

Embodiment 2

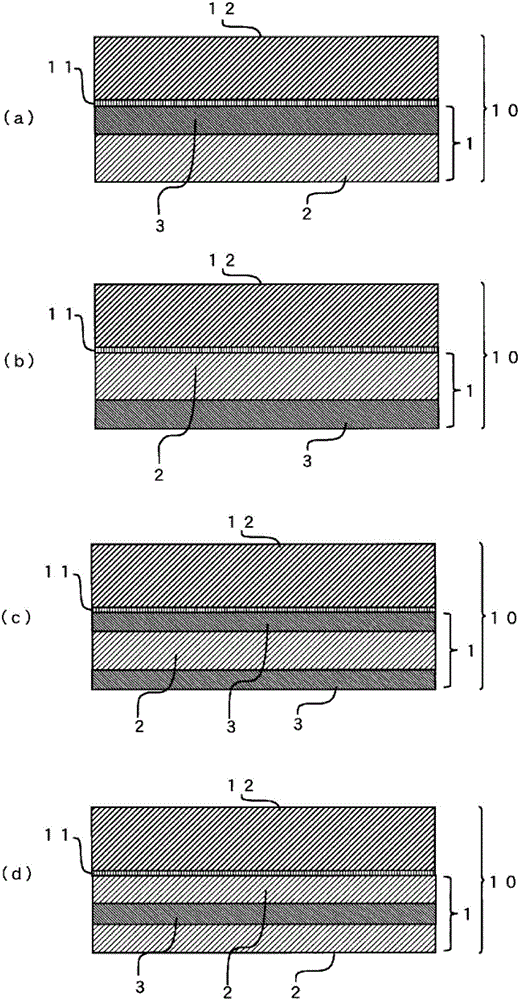

[0105] In embodiment 2, manufactured have figure 2 Composite metal foil with carrier foil with a layer structure of "copper layer 2 / nickel-molybdenum alloy layer 3 / copper layer 2 / peeling layer 11 / carrier 12" shown in (d) (implementation sample 5 to implementation sample 7), and have figure 2 Composite metal foil with carrier foil with a layer structure of "nickel-molybdenum alloy layer 3 / copper layer 2 / nickel-molybdenum alloy layer 3 / peeling layer 11 / carrier 12" shown in (c) (implementation sample 8) . Hereinafter, the manufacturing methods of Example 5 to Example 8 will be described.

[0106] Formation of carrier foils and release layers used in sample 5 to sample 8

[0107] Electrolytic copper foil with a thickness of 18 μm was used as the carrier foil, and on the surface of the carrier foil, the carrier foil was mixed with sulfuric acid 150 g / L, copper concentration 10 g / L, carboxybenzotriazole concentration 800 mg / L, and liquid temperature 30°C. Soak in the dilute su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com