LED light power supply assembly and LED lamp

A technology for LED lamps and photoelectric power sources, applied in the directions of light sources, lamp shades, circuit layouts, etc., can solve the problems of heavy weight, large proportion of volume and weight of LED photoelectric power source assemblies, and complex heat transfer paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

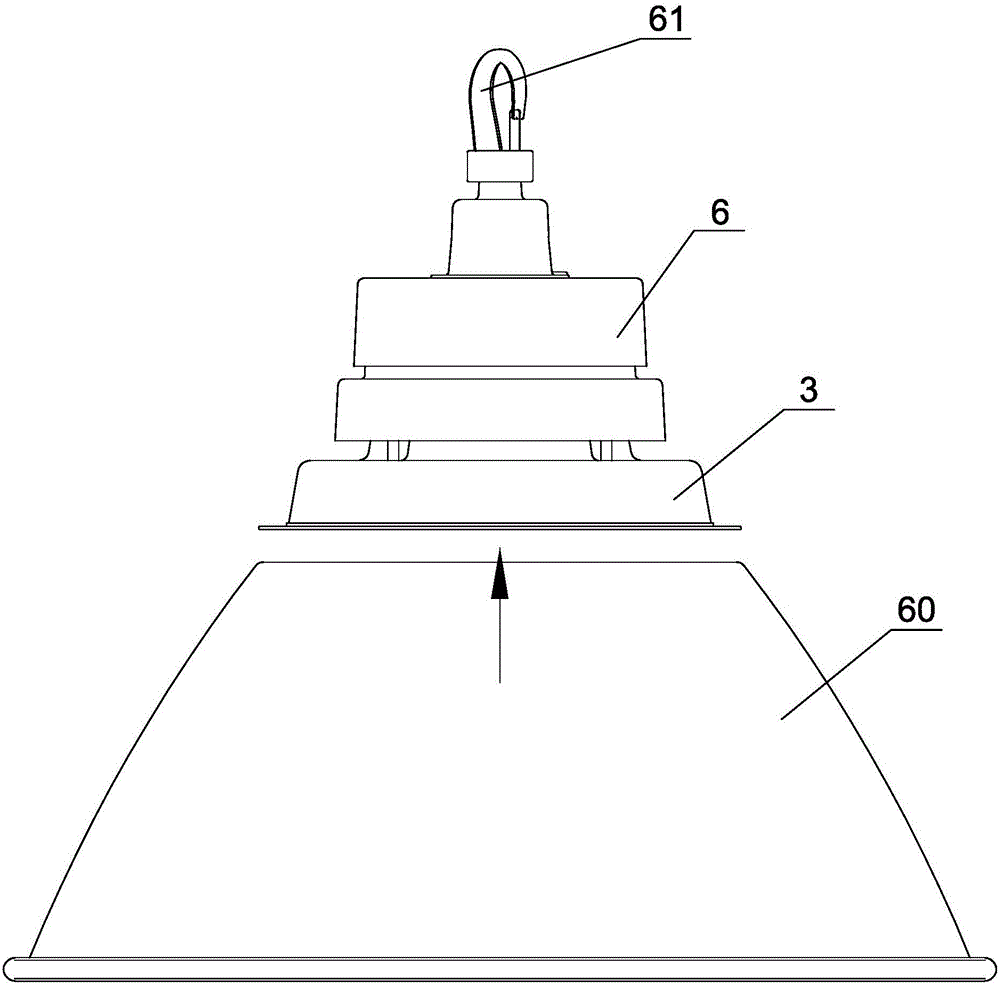

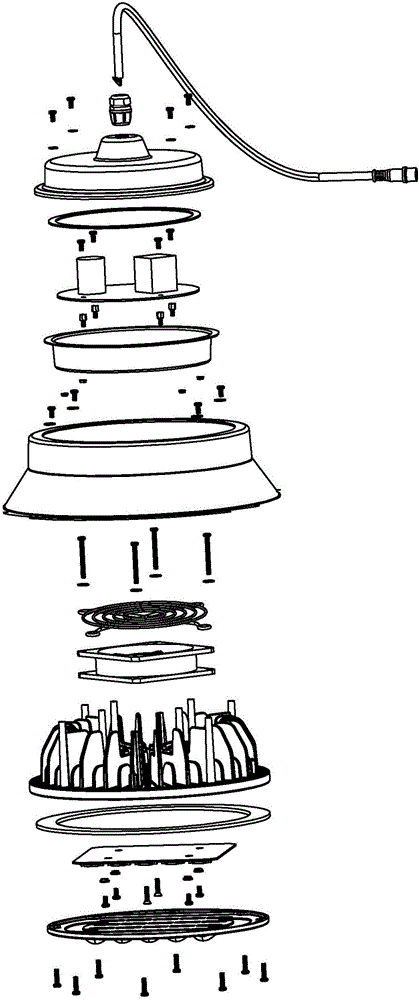

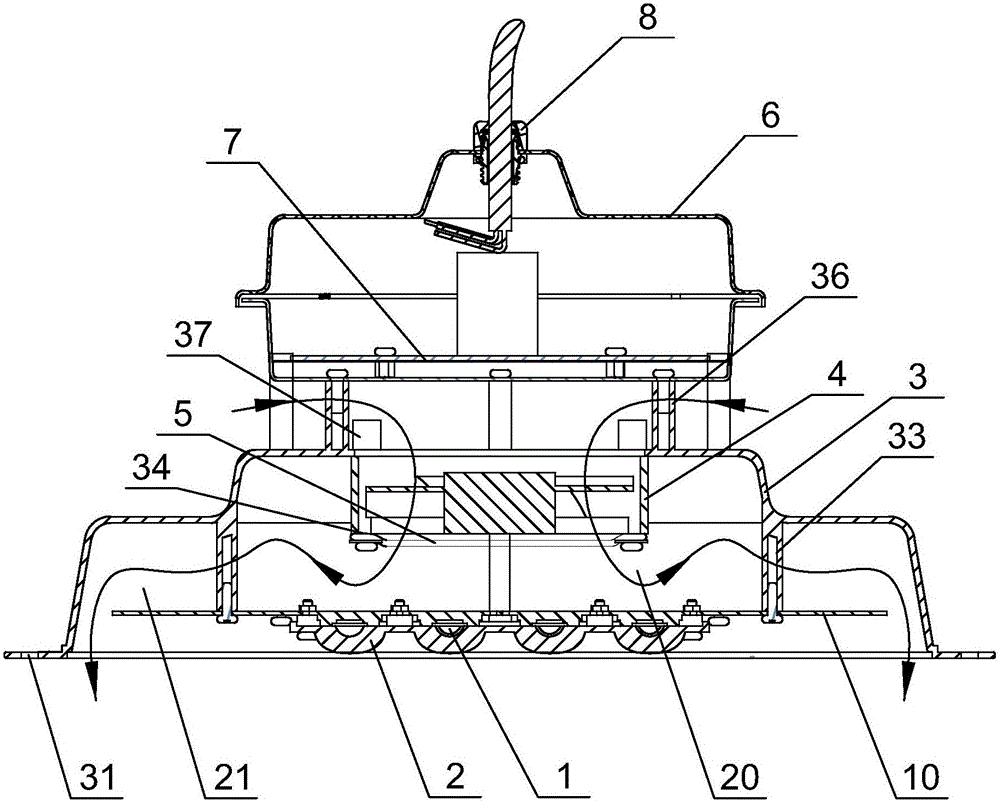

[0047] Such as figure 2 , Figure 7 ~ Figure 9 As shown, the LED optical power supply assembly of this embodiment includes a heat dissipation light source board 10 with a plurality of LED chips 1, a wind deflector 3, a heat dissipation fan 4, a power supply box assembly 6, and a driver located in the power supply box assembly 6. A circuit board assembly 7, a power supply harness assembly 8 for connecting the drive circuit board assembly 7 and the heat dissipation light source board 10 electrically, the LED light power supply assembly does not have a heat sink, and the wind guide The cover 3 is stepped and encloses a large-diameter cavity and a small-diameter cavity. The heat dissipation light source plate 10 is fixedly connected to the air deflector 3 and is located in the large-diameter cavity of the air deflector 3. The fan 4 is fixedly connected to the air deflector 3, the power supply box assembly 6 is fixedly connected to the air deflector 3 and is located above the air de...

Embodiment 2

[0050] Such as image 3 , Figure 7 , Figure 8 As shown, the difference between the LED optical power supply assembly of this embodiment and the first embodiment is that: in this embodiment, the LED optical power supply assembly further includes an extension stud 11, and the heat dissipation fan 4 is located in the air guide. Above the outside of the cover 3, the cooling fan 4 is fixedly connected to the fan outer pillar 37, and the extension stud 11 is connected to the power box pillar 36 to extend the length of the power box pillar 36 to adapt to The space brought by the external heat dissipation fan increases. Without changing the structure of the air deflector 3, it is convenient for the power supply box assembly 6 to be directly installed and fixed on the extension stud 11, so that the air deflector 3 It has a wide range of applications, reduces the types of accessories, and facilitates inventory; outside air enters from the annular tuyere, flows through the diversion area...

Embodiment 3

[0053] Such as Figure 4 , Figure 7 ~ Figure 9 As shown, the difference between the LED optical power supply assembly of this embodiment and the first embodiment is that: in this embodiment, the LED optical power supply assembly further includes a wind deflector 9, and the center of the wind deflector 9 is provided An air outlet, the air deflector 9 is fixedly connected to the air deflector 3 and the edge shields the front of the annular air outlet, so that the air flowing through the annular air outlet is diverted from the air outlet in the center of the air deflector 9 In and out, the inside of the air deflector 3 is provided with an air deflector pillar 32 supporting and fixing the air deflector 9; outside air enters from the air outlet in the center of the air deflector 9, flows through the annular air outlet and then turns into The diversion area 21 and the vortex flow in the vortex area 20 enters the heat dissipation fan 4, and the air flowing out of the heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com