A kind of all-cotton imitation cashmere fabric and its manufacturing method

A technology of imitating cashmere and fabrics, which is applied in the field of pure cotton imitation cashmere fabrics. It can solve the problems of insufficient softness and fineness, easy pilling, unsuitable shading texture, etc., achieve smooth hand feeling, improve bulkiness and softness, The effect of improving softness and delicateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

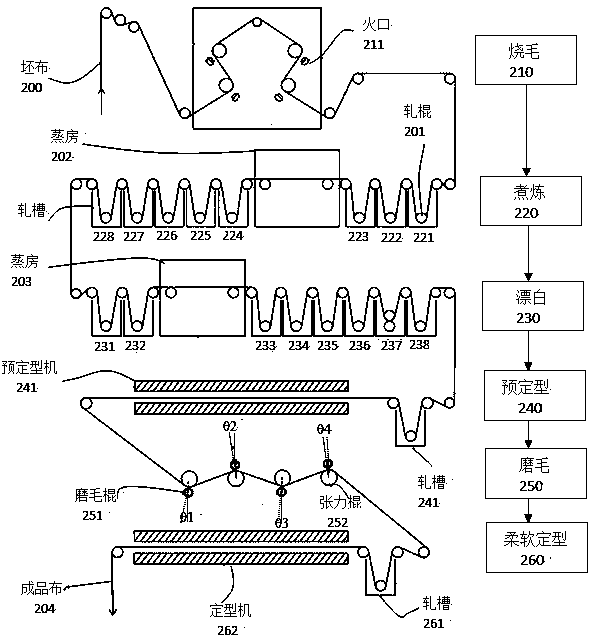

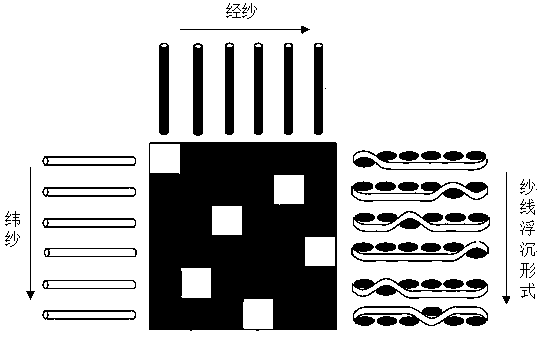

[0024] The pure cotton imitation cashmere fabric of the present embodiment: the warp yarn is 32 pure cotton single yarns, the weft yarn is 21 pure cotton single yarns, the warp and weft density of the gray cloth is 133*60 / inch, and the width of the gray cloth is 290cm. figure 2 The shown fabric structure is woven on an arrow loom to obtain a gray cloth 200 .

[0025] Gray fabric post-processing:

[0026] Singeing (210): gray cloth 200 according to figure 1 The process shown first passes through the singeing machine at a speed of 100m / min, the flame intensity of the burner 211 of the singeing machine is 15mbar, and the singeing method is double-sided singeing with one front and one back.

[0027] Scouring (220): The fabric after singeing is fed into the long car for boiling and bleaching at a speed of 40 m / min. The temperature of the rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com