A kind of preparation method of high temperature yellow pigment for ceramic laser printing

A yellow pigment and laser printing technology, which is applied in the field of high-temperature-resistant yellow pigment, can solve the problems of insufficient decoration methods, and achieve the effect of strong color development, complete coating, and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

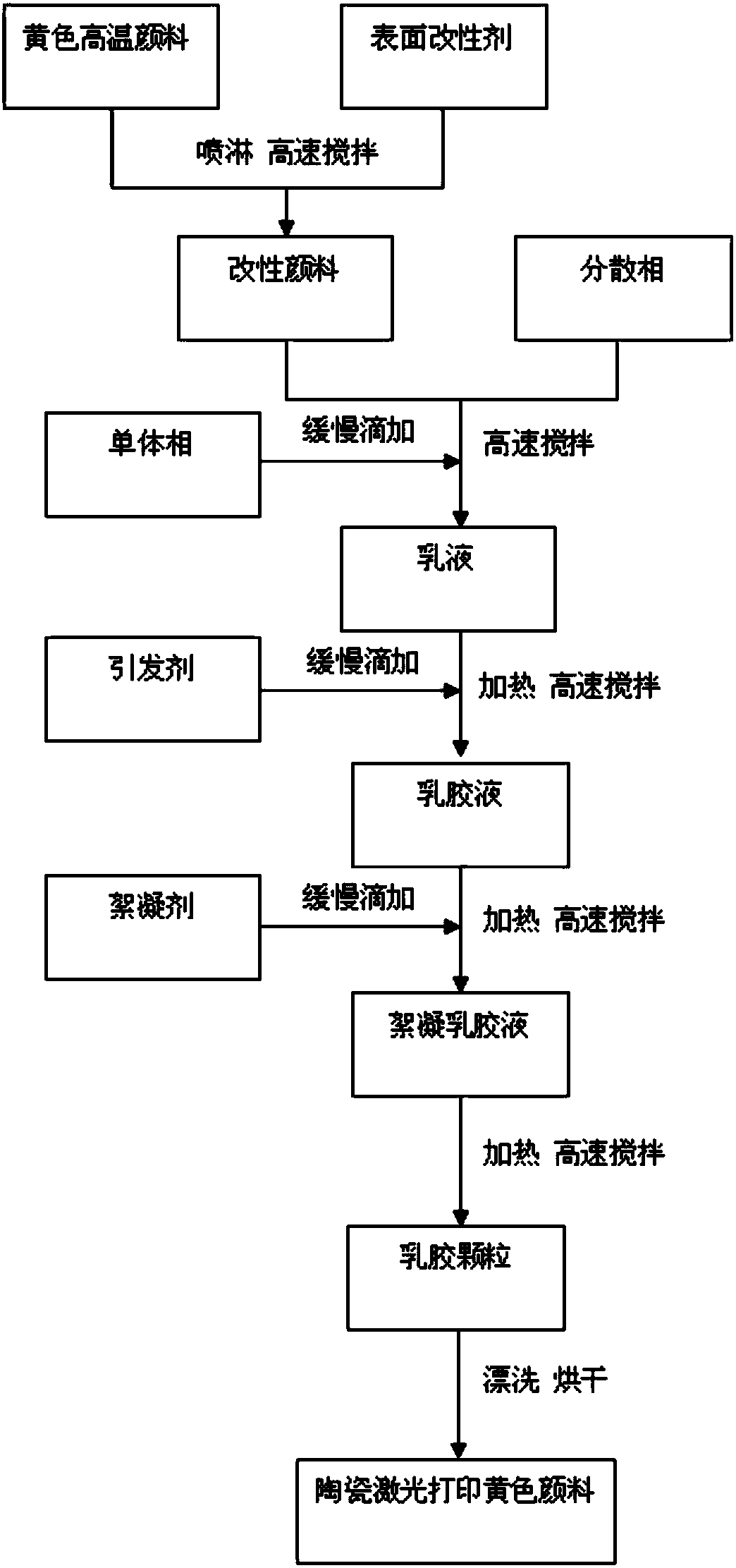

[0034] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

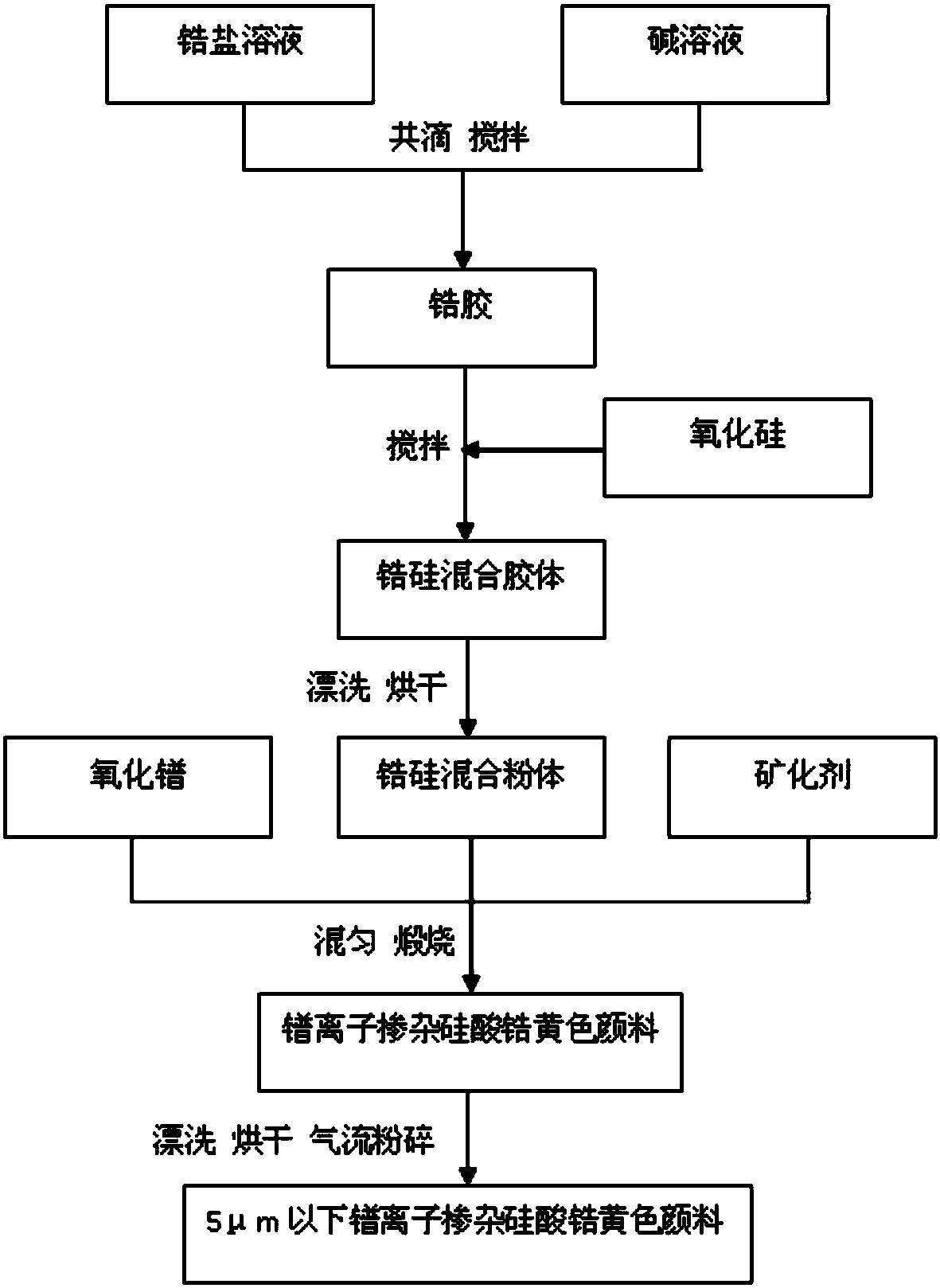

[0035] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0036] Drop an equal volume of 2mol / L zirconium oxychloride octahydrate solution and 3mol / L sodium hydroxide solution into continuously stirring water to form zirconium colloid. Continue stirring for 100min;

[0037] Massive Zr 4+ : Si 4+ =1:1.0 Add white carbon black to the zirconium colloid, and stir for 150 minutes to form a zirconium-silicon mixed colloid;

[0038] Discharge, press filter, wash the mixed colloid with water for 3 hours, and dry at 120°C for 48 hours to obtain a zirconium-silicon mixed powder;

[0039] Mix 86wt% zirconium-silicon mixed powder, 6wt% praseodymium oxide, 3wt% ammonium fluoride, and 5wt% ammonium chloride uniformly, calcinate at 900°C for 3 hours to obtain praseodymium ion-doped zirconium silicate ye...

Embodiment 2

[0050] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

[0051] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0052] Drop an equal volume of 1.5mol / L zirconium chloride solution and 4mol / L potassium hydroxide solution into the continuously stirring water to form zirconium colloid. During the synthesis process, control the pH=6~8, and continue stirring after the dropwise addition 120min;

[0053] Massive Zr 4+ : Si 4+ =1:1.1 Add white carbon black to the zirconium colloid, and stir for 120 minutes to form a zirconium-silicon mixed colloid;

[0054] Discharge, press filter, wash the mixed colloid with water for 4 hours, and dry at 130°C for 24 hours to obtain a zirconium-silicon mixed powder;

[0055] Mix 92wt% zirconium-silicon mixed powder, 5wt% praseodymium oxide, 1wt% sodium fluoride, and 2wt% potassium chloride evenly, and calcinate at ...

Embodiment 3

[0066] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

[0067] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0068] Drop an equal volume of 2.5mol / L zirconium sulfate solution and 4mol / L sodium carbonate solution into the continuously stirring water to form zirconium colloid. During the synthesis process, control the pH=6~8, and continue stirring for 90min after the dropwise addition;

[0069] Massive Zr 4+ : Si 4+ =1:1.1 Add quartz powder to the zirconium colloid, and stir for 180min to form zirconium-silicon mixed colloid;

[0070] Discharge, press filter, wash the mixed colloid with water for 2 hours, and dry at 100°C for 72 hours to obtain a zirconium-silicon mixed powder;

[0071] Mix 88wt% zirconium-silicon mixed powder, 6wt% praseodymium oxide, 2wt% sodium fluoride, and 4wt% potassium chloride evenly, and calcinate at 950°C for 3 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com