Preparation method of blue pigment for coating/ink-jet printing/nano-zirconia ceramic

A nano-zirconia, inkjet printing technology, applied in applications, coatings, inks, etc., can solve the problems of uneven particle size, wide particle size distribution, and different morphology of pigments, and achieve strong chemical stability and particle size. Narrow distribution, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

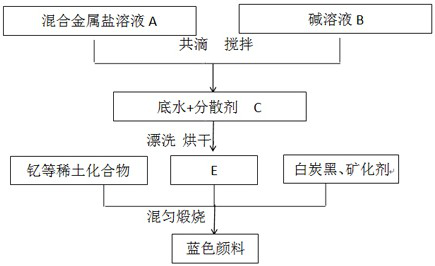

[0027] A preparation method of blue pigment for coating / inkjet printing / nano zirconia ceramics, comprising the steps of:

[0028] (1) Take 5.75g CrCl 3 . 6H 2 O, 237.5g CoCl 2 . 6H 2 O, 502.5g AlCl 3 . 6H 2 O, 4.2gZnCl 2 Dissolved in 5000mL of water as liquid A; 250g of Na 2 CO 3 Dissolved in 5000mL of water to obtain liquid B; dissolved 0.5g polyethylene glycol-1000 in 2000mL of water to obtain liquid C; drop A and B into C to keep the pH at 8 to obtain liquid D. After stirring for 1 hour, wash with water until D is free. Until the ions are washed out, dry at 120°C and crush through 200 meshes to obtain E; mix 0.5 wt% yttrium, neodymium rare earth compound, 1 wt% borax, 2.5 w% white carbon black and E into a crucible, 900°C Calcined for 120 minutes, washed with water and jet milled.

Embodiment 2

[0030] Take 5.75g CrCl 3 . 6H 2 O, 237.5g CoCl 2 . 6H 2 O, 502.5g AlCl 3 . 6H 2 O, 4.2gZnCl 2 Soluble in 5000mL water as A 1 solution; 250 g Na 2 CO 3 Dissolved in 5000mL water as B 1 liquid; 0.5g polyethylene glycol-1000 dissolved in 2000mL water is C 1 ; put A 1 and B 1 Co-dropping in C to maintain pH 8 gives D 1 solution, stirred for 1 hour, washed with water until D 1 Until no ions are washed out, dry at 120°C and pulverize through 200 meshes for E 1 ; 0.5 wt% yttrium, neodymium rare earth compound, 1 wt% borax, 2.5 w% silica and E 1 Mix well and put into crucible, calcined at 1000°C for 60 minutes, washed with water and jet crushed.

Embodiment 3

[0032] Take 5.75g CrCl 3 . 6H 2 O, 237.5g CoCl 2 . 6H 2 O, 502.5g AlCl 3 . 6H 2 O, 4.2gZnCl 2 Soluble in 5000mL water as A 2 solution; 250 g Na 2 CO 3 Dissolved in 5000mL water as B 2 liquid; 0.5g polyethylene glycol-1000 dissolved in 2000mL water is C 2 ; put A 2 and B 2 Co-dropping in C to maintain pH 8 gives D 2 solution, stirred for 1 hour, washed with water until D 2 Until no ions are washed out, dry at 120°C and pulverize through 200 meshes for E 2 ; 2.5 w% silica and E 2 Mix well and put into crucible, calcined at 1000°C for 60 minutes, washed with water and jet crushed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com