Preparation method of high-temperature yellow pigment for ceramic laser printing

A yellow pigment and laser printing technology, applied in the field of high temperature resistant yellow pigment, can solve the problems of insufficient decoration means, and achieve the effect of strong color development, rapid electrification and complete coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

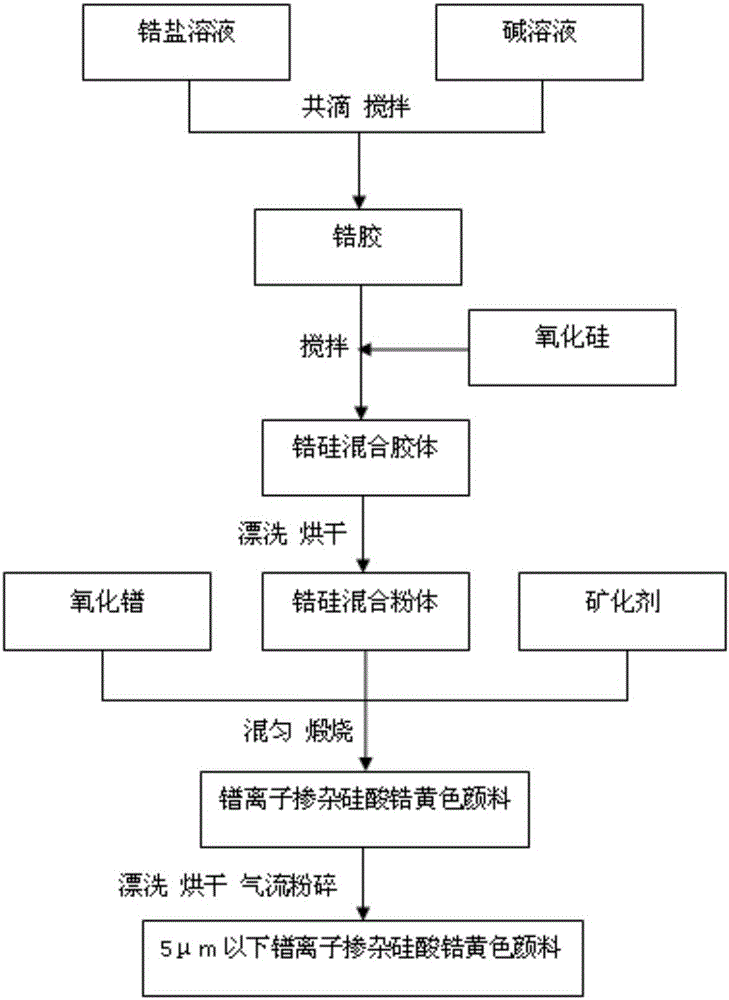

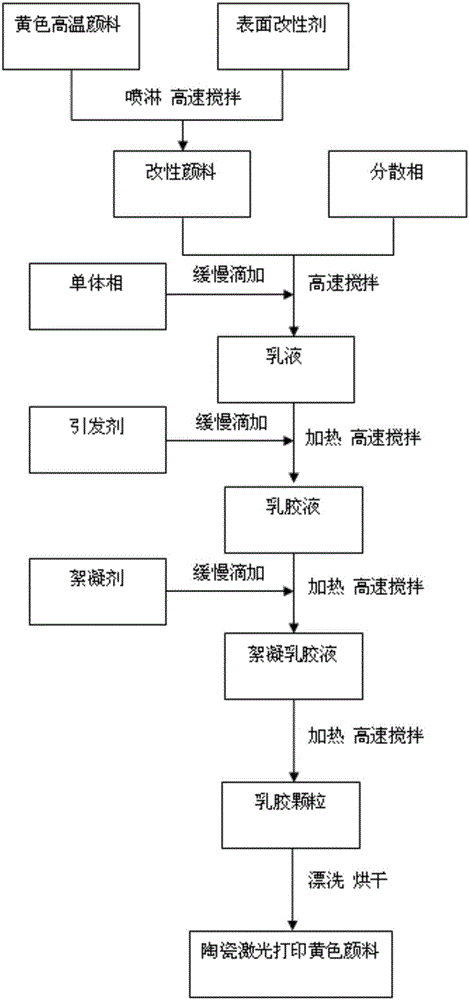

[0035] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0036] Drop an equal volume of 2mol / L zirconium oxychloride octahydrate solution and 3mol / L sodium hydroxide solution into continuously stirring water to form zirconium colloid. Continue stirring for 100min;

[0037] Massive Zr 4+ : Si 4+ =1:1.0 Add white carbon black to the zirconium colloid, and stir for 150 minutes to form a zirconium-silicon mixed colloid;

[0038] Discharge, press filter, wash the mixed colloid with water for 3 hours, and dry at 120°C for 48 hours to obtain a zirconium-silicon mixed powder;

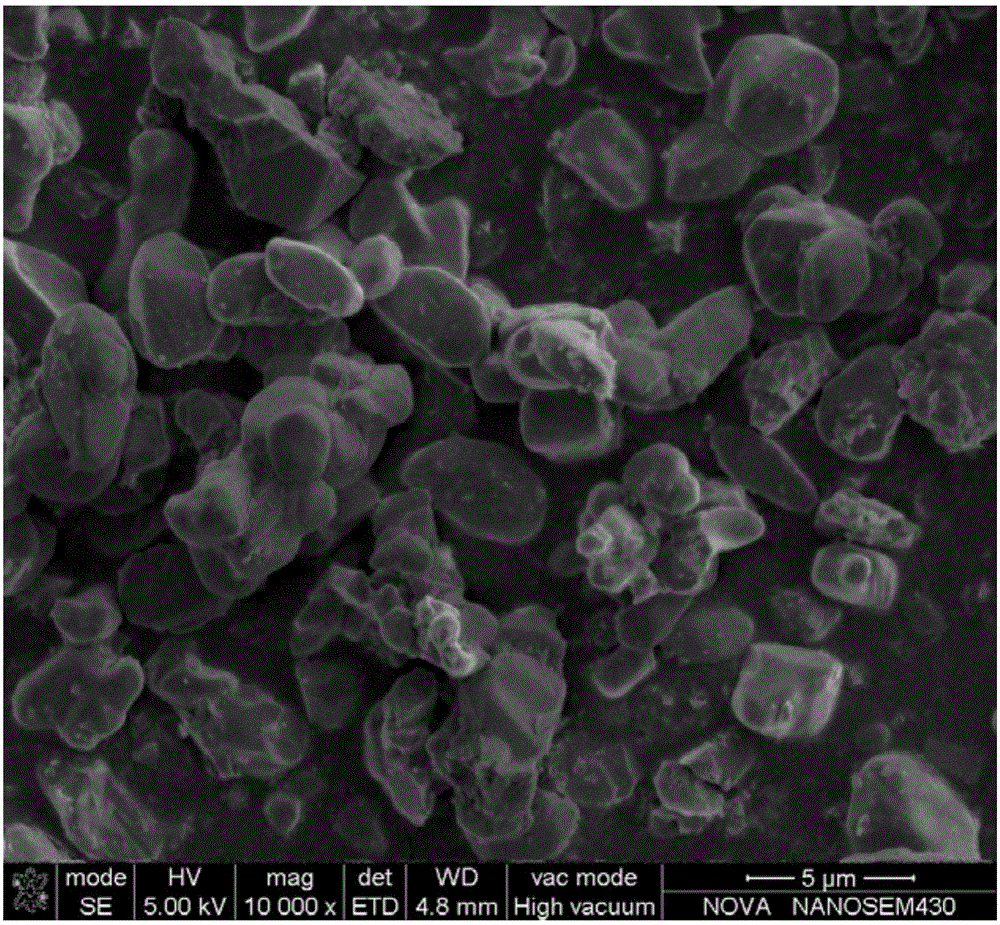

[0039] Mix 86wt% zirconium-silicon mixed powder, 6wt% praseodymium oxide, 3wt% ammonium fluoride, and 5wt% ammonium chloride uniformly, calcinate at 900°C for 3 hours to obtain praseodymium ion-doped zirconium silicate ye...

Embodiment 2

[0050] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

[0051] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0052] Drop an equal volume of 1.5mol / L zirconium chloride solution and 4mol / L potassium hydroxide solution into the continuously stirring water to form zirconium colloid. During the synthesis process, control the pH=6~8, and continue stirring after the dropwise addition 120min;

[0053] Massive Zr 4+ : Si 4+ =1:1.1 Add white carbon black to the zirconium colloid, and stir for 120 minutes to form a zirconium-silicon mixed colloid;

[0054] Discharge, press filter, wash the mixed colloid with water for 4 hours, and dry at 130°C for 24 hours to obtain a zirconium-silicon mixed powder;

[0055] Mix 92wt% zirconium-silicon mixed powder, 5wt% praseodymium oxide, 1wt% sodium fluoride, and 2wt% potassium chloride evenly, and calcinate at ...

Embodiment 3

[0066] A preparation method of a high-temperature yellow pigment for ceramic laser printing, comprising the steps of:

[0067] (1) Synthesis of praseodymium ion-doped zirconium silicate yellow pigment by semi-liquid and semi-solid phase method

[0068] Drop an equal volume of 2.5mol / L zirconium sulfate solution and 4mol / L sodium carbonate solution into the continuously stirring water to form zirconium colloid. During the synthesis process, control the pH=6~8, and continue stirring for 90min after the dropwise addition;

[0069] Massive Zr 4+ : Si 4+ =1:1.1 Add quartz powder to the zirconium colloid, and stir for 180min to form zirconium-silicon mixed colloid;

[0070] Discharge, press filter, wash the mixed colloid with water for 2 hours, and dry at 100°C for 72 hours to obtain a zirconium-silicon mixed powder;

[0071] Mix 88wt% zirconium-silicon mixed powder, 6wt% praseodymium oxide, 2wt% sodium fluoride, and 4wt% potassium chloride evenly, and calcinate at 950°C for 3 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com