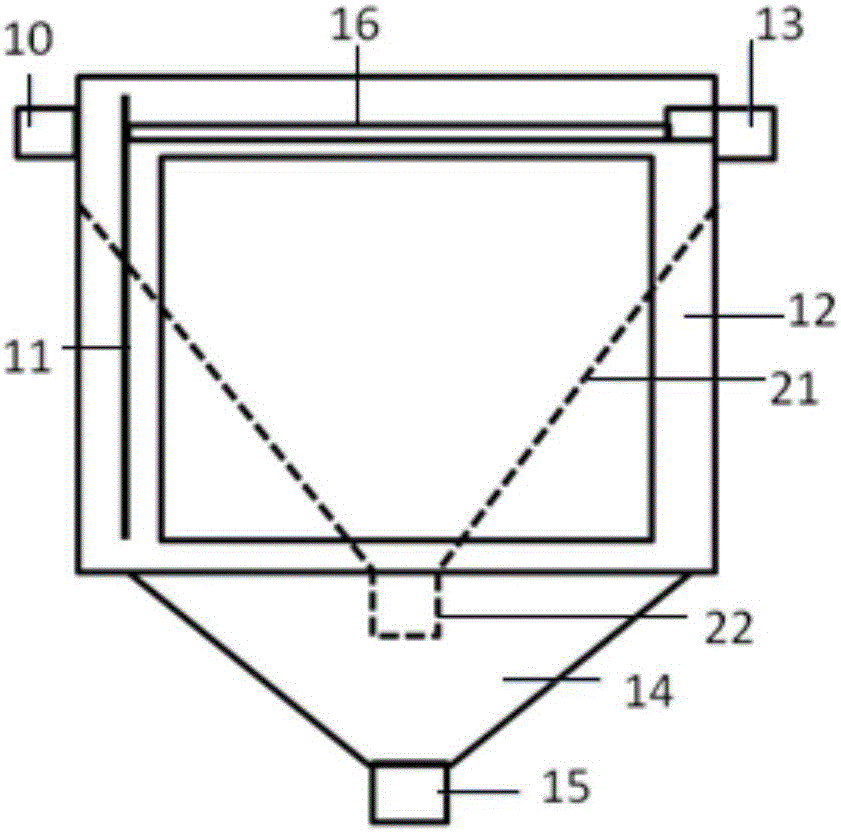

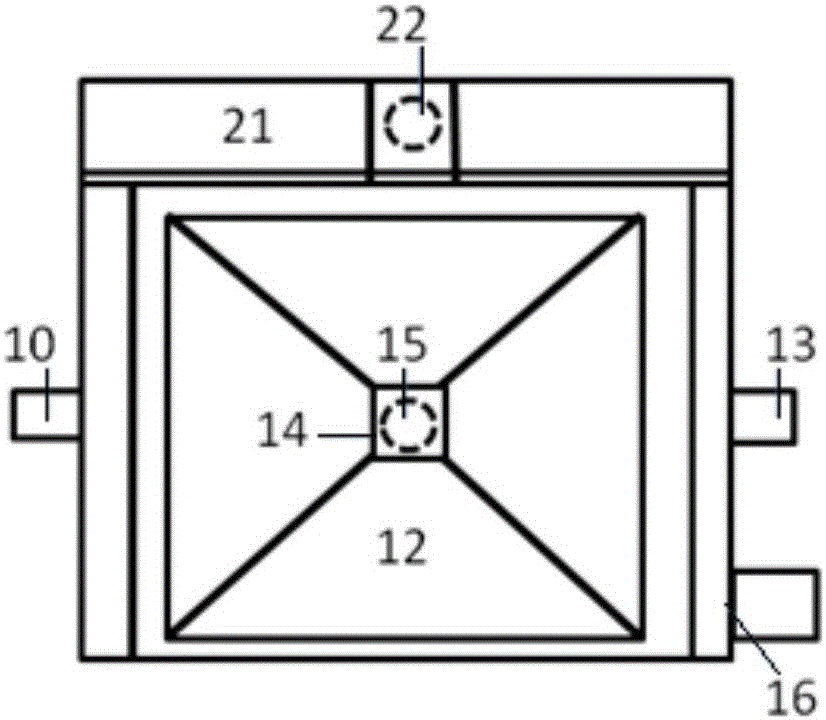

Water treatment device and method using photoelectrocatalysis purification

A photoelectric catalysis and treatment device technology, applied in the field of water treatment, can solve the problems of difficult large-scale application, high overall energy consumption, high current density, etc., and achieve the effects of small space occupation, low treatment cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one, cooling circulating water:

[0045] A large amount of cooling circulating water is needed in the industrial production process, and this water needs to be softened before it can be used. After repeated cycles, due to the evaporation of water, calcium, magnesium ions, and organic matter (bacteria) in the water will accumulate, making the pipeline easy to block. The index of typical cooling cycle raw water is TDS is 800mg / L, Ca 2+ 150mg / L, Mg 2+ 40mg / L, COD 50mg / L. After adopting the photoelectric catalytic purification water treatment device of the present invention at a voltage of DC12V, a current density of 0.1mA / cm 2 , energy consumption is 0.12KWh / m 3 , water index after 30min treatment, TDS is 530mg / L, Ca 2+ 60mg / L, Mg 2+ 10mg / L, COD 20mg / L; water index after 60min treatment, TDS 310mg / L, Ca 2+ 12mg / L, Mg 2+ 2mg / L, COD 6mg / L. PEC can be used for on-line softening of cooling circulating water and removal of organic matter.

Embodiment 2

[0046] Embodiment two, printing and dyeing wastewater:

[0047] Printing and dyeing wastewater contains a variety of organic compounds, including benzene, phenol, azo compounds, and phosphorus, sulfur and other compounds. The wastewater is highly toxic, dark in color, and has poor biochemical properties. It is a difficult wastewater to treat. Generally, chemical flocculation, fresh water dilution, and microbial treatment are used, and the treatment cost is relatively high. Typical printing and dyeing wastewater, COD is 1500mg / L, TDS is 600mg / L, and the color is dark blue, which can be directly treated by the photoelectric catalytic water purification treatment device of the present invention, with a voltage of DC12V and a current density of 0.2mA / cm 2 , energy consumption is 0.3KWh / m 3 , each treatment time is 30min. After 3 cycles of treatment, the COD is 40mg / L, with a removal rate of over 98%, the soluble solid TDS is 350mg / L, a drop of over 40%, and other indicators such...

Embodiment 3

[0048] Embodiment three, culture waste water:

[0049] Aquaculture wastewater is discharged in large quantities in rural areas, causing serious environmental pollution. This type of wastewater has good biodegradability. For large-scale farms, typical microbial processes including anaerobic and aerobic processes can be used for treatment, and the generated biogas can also be used for heat or power generation. For small and medium-sized farms, because the amount of wastewater produced is unstable, and the microbial treatment covers a large area and the treatment cycle is long, the generated biogas and biogas slurry are not suitable for treatment, and the relative cost is relatively high, so it is not suitable for application. Taking small and medium-sized pig farms as an example, the wastewater from pig farms is mainly waste water such as feces and urine and feed washing, black and yellow wastewater, containing high-concentration organic matter, ammonia nitrogen, sulfide, bacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com