Saccharomyces cerevisiae degrading zearalenone toxins and application thereof

A technology of zearalenone and yeast, which is applied to the application field of Saccharomyces cerevisiae in the field of feed and food safety, can solve problems such as environmental pollution and impact on the application of biological control technology, and achieve avoidance of harm to humans, significant economic benefits and Social benefit, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the screening of the yeast that degrades ZEA, specific implementation steps are as follows:

[0028] 1. Isolation of yeast single colonies from the environment

[0029] Take mulberries, squeeze the juice, take 1ml of the juice, add it to a centrifuge tube filled with 10ml of sterile water, shake and mix well, take the mixed solution, and do gradient dilution (10 -4 , 10 -5 , 10 -6 , 10 -7 ), spread on NYDA medium plate, and culture at 28°C for 20-36h. Pick the dominant yeast single colony and purify and culture it on the NYDA plate. The isolated and purified strains were planted on NYDA slopes, cultured at 28°C for 48 hours, and stored in a refrigerator at 4°C for short-term storage.

[0030] 2. ZEA determination method

[0031] Adopt the method (HPLC-FLD) of high performance liquid phase-fluorescence detector to detect ZEA, the condition is as follows, chromatographic column: Agilent C 18 Column (5.0μm, 150.0mm×4.6mm); mobile phase: acetonitrile: 1...

Embodiment 2

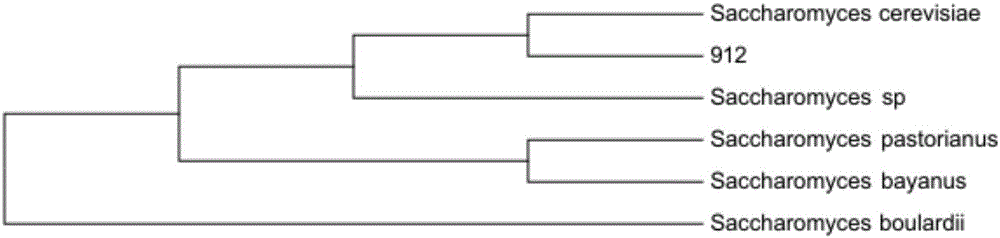

[0039] Example 2: Microbiological properties of Saccharomyces cerevisiae 912

[0040] The above-mentioned strain 912 was identified as Saccharomyces cerevisiae through morphological culture, physiological and biochemical characteristics tests, and nucleotide sequence analysis of small subunit 5.8SrDNA and internal transcriptional spacer ITS1 and ITS2 regions.

[0041] The bacterial strain Saccharomyces cerevisiae 912 bacterial strain of the present invention (has applied for Chinese invention patent, application number 201310648466.8, title of invention: Saccharomyces cerevisiae, application and method of use in fruit postharvest disease control, application date: December 04, 2013) has the following microorganisms Academic Features:

[0042] 1. Morphological characteristics

[0043] (1) Cultured on a YEPD solid medium plate (yeast powder 10g, peptone 20g, glucose 20g, distilled water 1000mL, agar 20g, pH 6.0, 115°C damp heat sterilization for 20min) at 28°C for 48h, the colo...

Embodiment 3

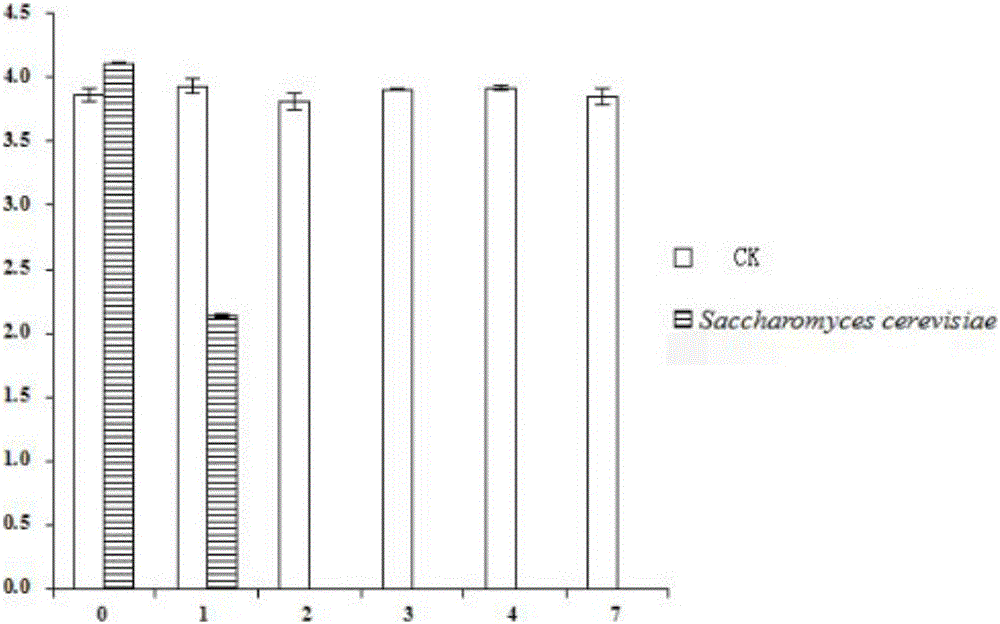

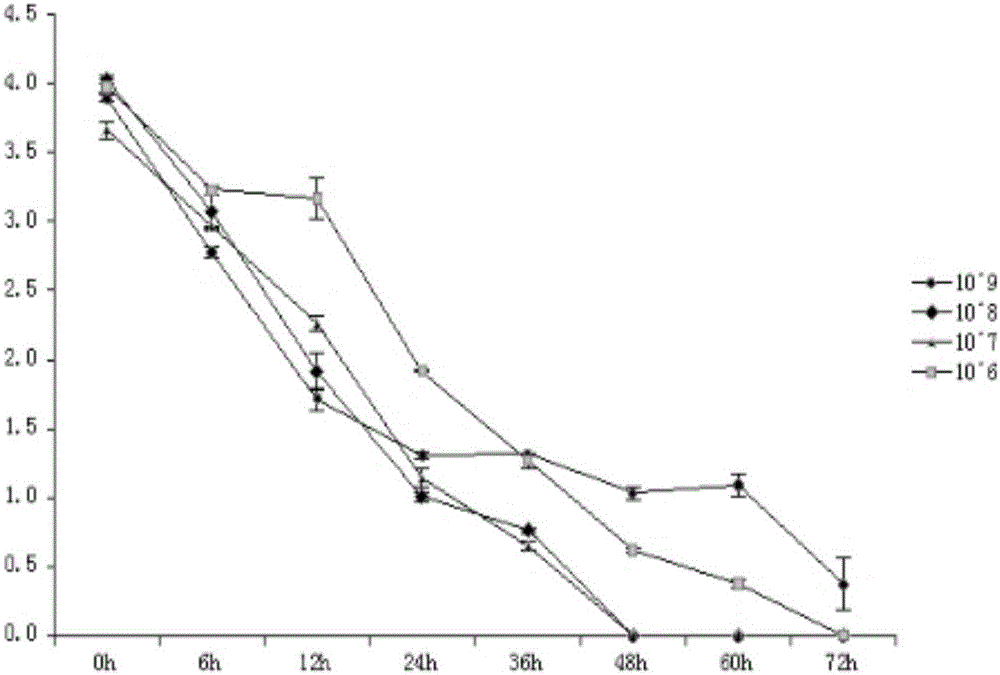

[0051] Example 3: Optimization of ZEA Degradation Conditions by Saccharomyces cerevisiae 912

[0052] By studying the effect of Saccharomyces cerevisiae 912 on the degradation of ZEA under the conditions of bacterial concentration, culture temperature, shaker speed, medium pH and different initial concentrations of ZEA, it was determined that the optimal condition for its degradation of ZEA was that the initial concentration of yeast was 10 8 CFU / mL, pH 6, shaker incubation temperature 28°C, rotation speed 180rpm, and with the increase of the initial concentration of ZEA, the time required for complete degradation prolongs. When the initial concentration of ZEA was 3 μg / mL, the yeast’s degradation rate was 100% after 36 h; 100%; when the initial concentration of ZEA was 8μg / mL and 10μg / mL, the degradation rates of ZEA were 95% and 84% after 72h.

[0053] The results show that Saccharomyces cerevisiae 912 of the present invention can continuously degrade the ZEA standard produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com