Steel wire for bolts, bolt, and methods for manufacturing same

A technology for bolts and steel wires, applied in the field of steel wires for bolts, can solve the problems of water quenching strength deviation, improper rolling temperature and wire drawing processing rate, difficulty in delayed fracture resistance, etc., and achieve excellent delayed fracture resistance. , The effect of preventing crystal coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0140] Hereinafter, the present invention is described in more detail by enumerating the examples, but the present invention is not limited by the following examples, and can also be modified and implemented within the scope of being able to meet the purpose of the foregoing and the following, and these are all included in the technical scope of the present invention Inside.

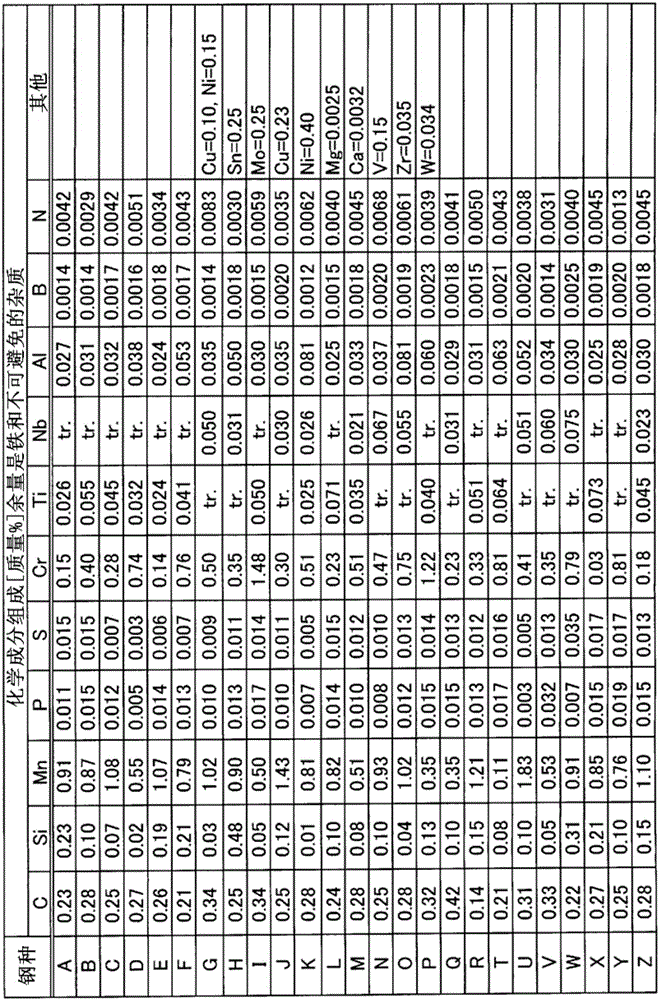

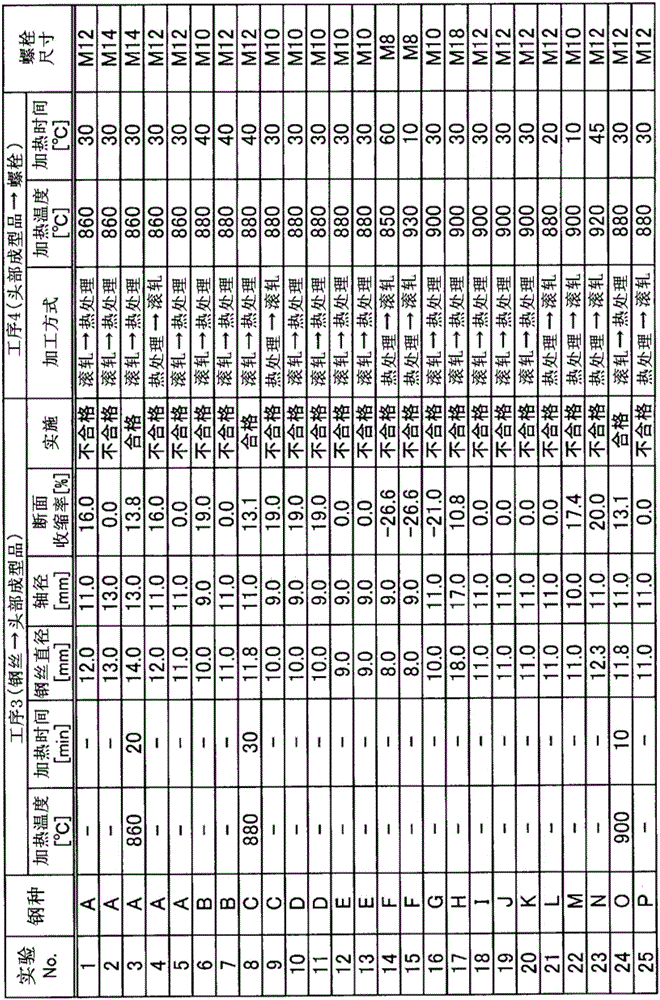

[0141] After melting the steel materials of steel types A to Z shown in Table 1 below, a steel billet with a square cross section and 155 mm in one side was produced. In addition, "tr." in Table 1 indicates that it is lower than the analysis limit value of each element. Thereafter, the billet is processed into a wire rod (process 1), the wire rod is processed into a bolt wire (process 2), the bolt wire is processed into the shape of a head molded product (process 3), and the head molded product is processed into a bolt ( Step 4), making various flange bolts (tensile strength 1000-1400MPa, M10-14 (coarse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com