One-chamber multi-mode metal cylinder chamber filter

A metal cylinder and filter technology, applied in the field of filters, can solve the problems of small tuning range and difficult processing, and achieve the effect of simple structure, easy processing and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

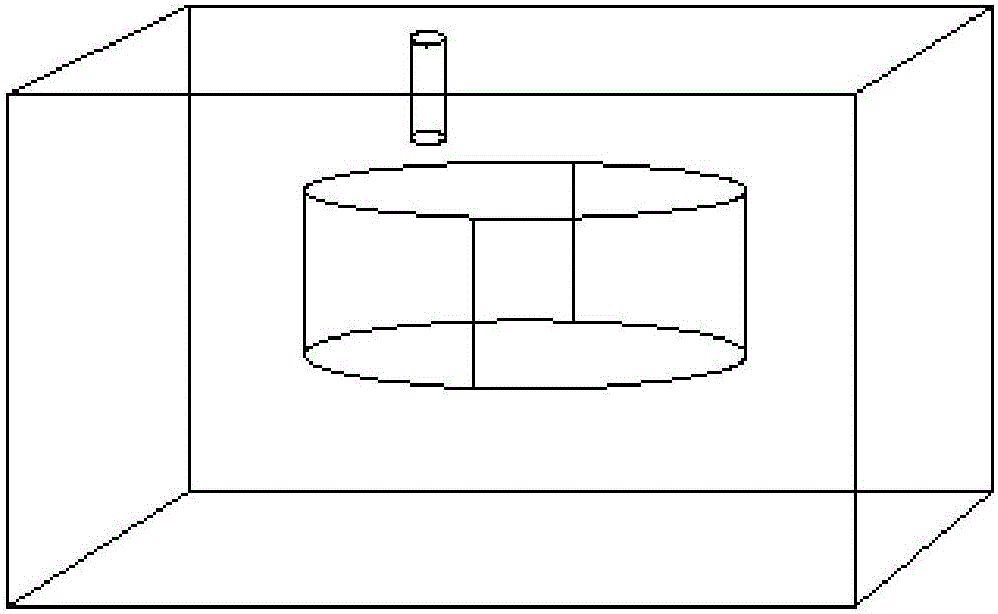

[0034] Such as Figure 7 to Figure 9 As shown, the metal cylindrical cavity filter described in this embodiment includes a cylindrical cavity 1, two end caps 2, 3, two metal rods 4, 5 and two feed units, the cylindrical cavity Both ends of the body 1 are open and sealed with end caps 2 and 3, the shape and size of the end caps match the shape and size of the corresponding openings, and the two feed units are respectively installed at the two ends of the cylindrical cavity 1 At the center of the covers 2, 3, two metal rods 4, 5 are symmetrically placed in the cylindrical cavity 1, and vertically installed in the middle of the side wall of the cylindrical cavity 1. In this embodiment, the metal rods 4 and 5 are uneven cylinders, and the uneven cylinders are formed by connecting two cylindrical sections with different thicknesses. In addition, the feed unit is composed of a probe 6, an SMA connector 7, and a disk 8. The probe 6 is vertically inserted on the end cover, and one en...

Embodiment 2

[0036] The difference from Embodiment 1 is that the metal rod described in this embodiment is a uniform cylinder (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com