Method for producing lithium ion battery silicon cathode through combination of laser cladding, diffusion welding and dealloying

A lithium-ion battery, laser cladding technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of improving uniformity, uniform composition, and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Raw materials:

[0023] (1) Aluminum silicon powder (-325 mesh, 99%), Al:Si=95:5wt.%.

[0024] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0025] (3) Etching solution: 3mol / L HCL solution.

[0026] 2. Preparation method

[0027] 1. Preparation of Al-Si Alloy Precursor:

[0028] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 1.5mm, use IPG fiber laser for cladding, laser power: 4.5kW, spot diameter: 5mm, scanning speed: 2mm / s, protective gas: argon, protective gas flow rate: 15L / min, and then use wire cutting to separate the cladding layer from the substrate to obtain the precursor alloy material.

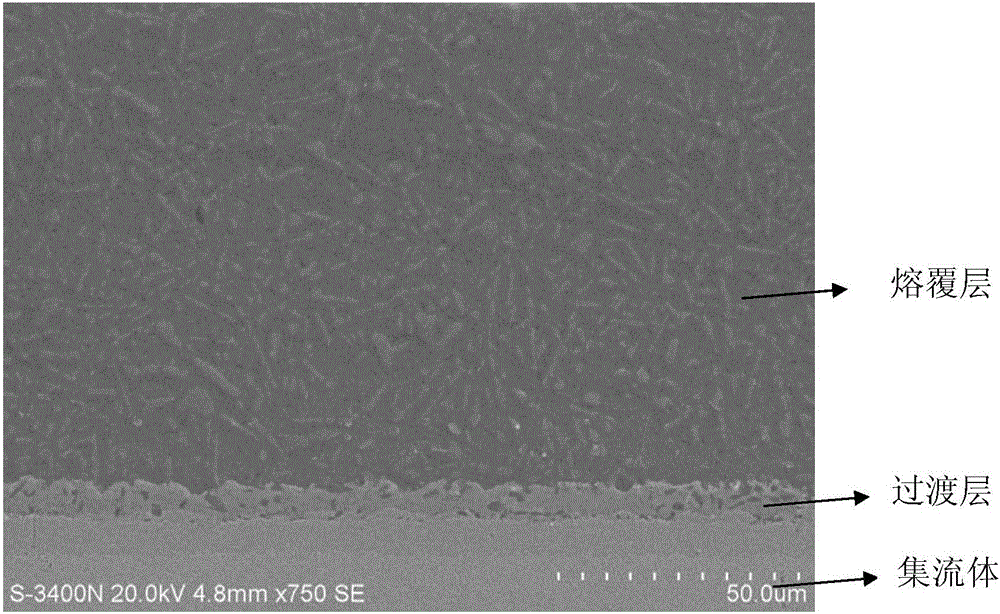

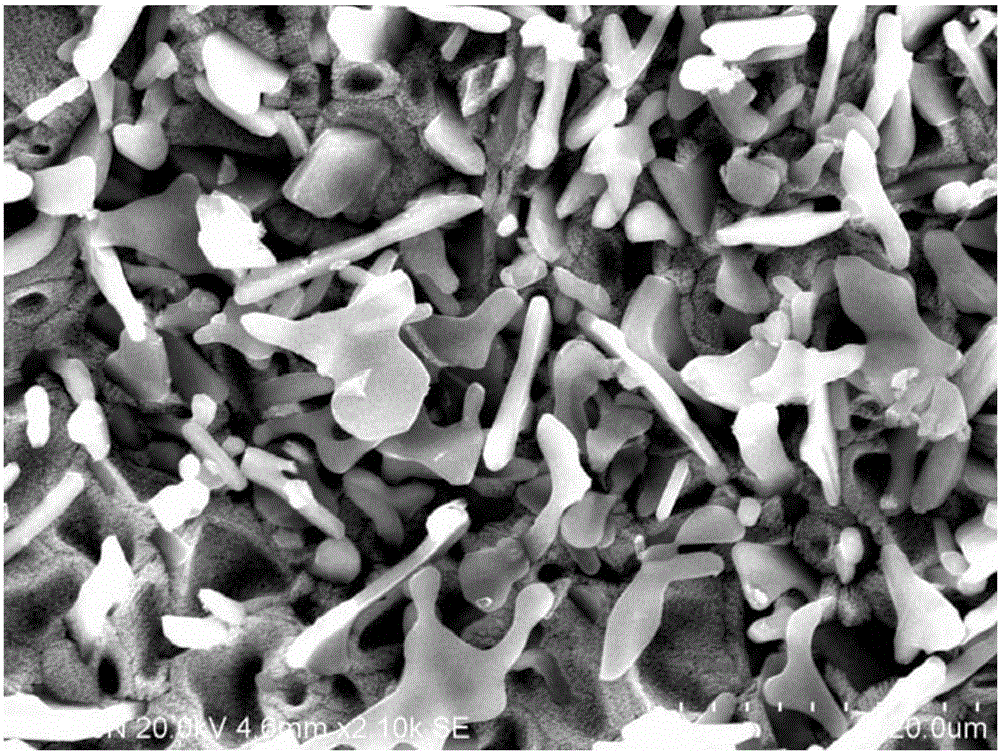

[0029] 2. Diffusion welding:

[0030] The aluminum-silicon alloy precursor is closely attached to the copper current collector, the aluminum-silicon cladding layer is closely attached to the copper current collector, placed in a vacuum atmosphere and heated for 1 hour, and the tempera...

Embodiment 2

[0034] 1. Raw materials:

[0035] (1) Aluminum silicon powder (-325 mesh, 99%), Al:Si=88:12wt.%.

[0036] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0037] (3) Etching solution: 3mol / L HCL solution.

[0038] 2. Preparation method

[0039] 1. Preparation of Al-Si alloy precursor:

[0040] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 2mm, use IPG fiber laser YLS-6000 for cladding, laser power: 5kW, spot diameter: 5mm, scanning speed: 4mm / s, protective gas: argon, protective gas flow rate: 15L / min, and then use wire cutting to separate the cladding layer from the substrate to obtain the precursor alloy material.

[0041] 2. Diffusion welding:

[0042] The aluminum-silicon alloy precursor and the copper current collector are closely attached, heated in a vacuum for 1 hour, and the temperature is raised from room temperature to 520°C, and a pressure of 0.5KPa is applied to it, so that the mi...

Embodiment 3

[0046] 1. Raw materials:

[0047] (1) Aluminum-silicon alloy powder (-325 mesh, 99%), Al:Si=50:50wt.%.

[0048] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0049] (3) Etching solution: 3mol / L HCL solution.

[0050] 2. Preparation method

[0051] 1. Preparation of Al-Si alloy precursor:

[0052] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 1.5mm, use IPG fiber laser YLS-6000 for laser cladding, laser power: 5.5kW, spot diameter: 5mm, scanning Speed: 6mm / s, protective gas: argon, protective gas flow rate: 15L / min, and then use wire cutting to separate the cladding layer from the substrate to obtain the precursor alloy material.

[0053] 2. Diffusion welding:

[0054] The aluminum-silicon alloy precursor and the copper current collector are closely attached, heated in a vacuum for 1 hour, and the temperature is raised from room temperature to 520°C, and a pressure of 0.5KPa is applied to it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com