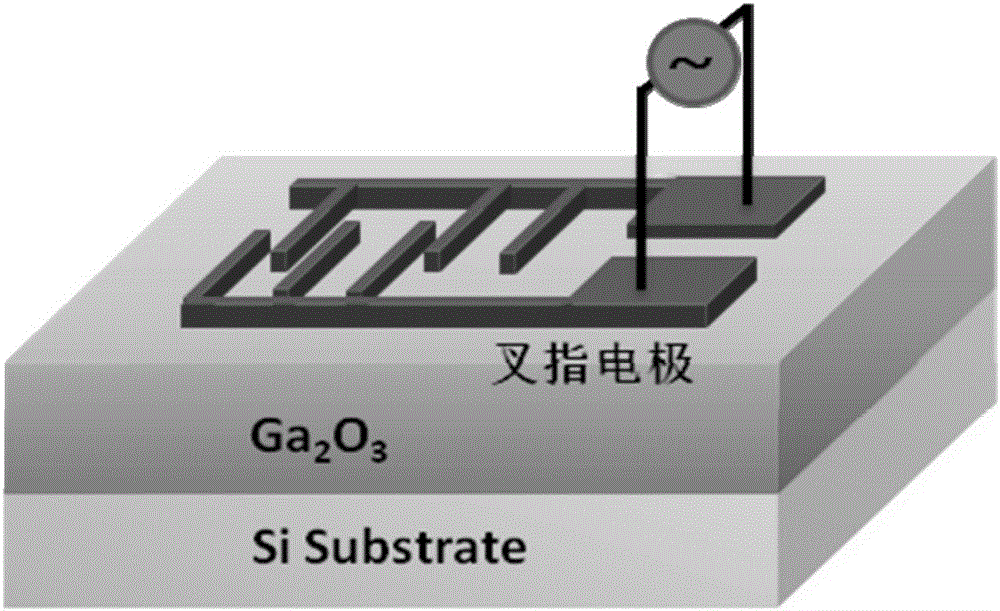

Novel flame detector based on gallium oxide film and preparation method thereof

A flame detector, gallium oxide technology, applied in electric radiation detectors, radiation pyrometry, sensing radiation from gas/flame, etc., can solve problems such as weak signal processing ability, sunlight interference, etc., and achieve reaction Sensitive, stable performance, small dark current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Proceed as follows:

[0028] 1) Pretreatment of n-type Si substrate: put n-type Si substrate into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonic cleaning with acetone, ethanol and deionized water respectively, and vacuum drying;

[0029] 2) Place the target and substrate: place the Ga 2 o 3 The target is placed on the target stage of the RF magnetron sputtering system, and the n-type Si substrate processed in step 1) is fixed on the sample holder and put into the vacuum chamber;

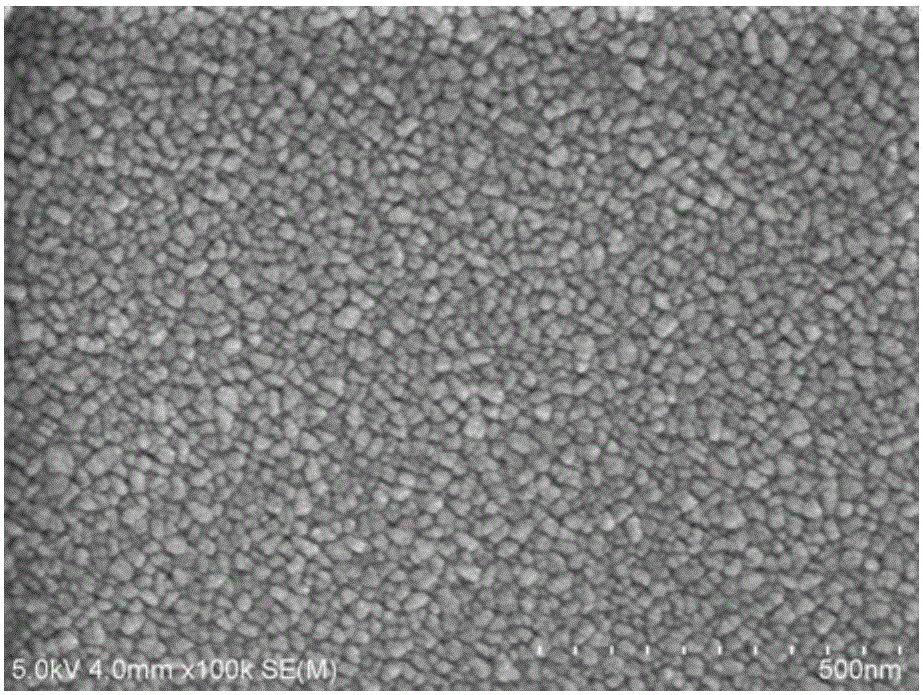

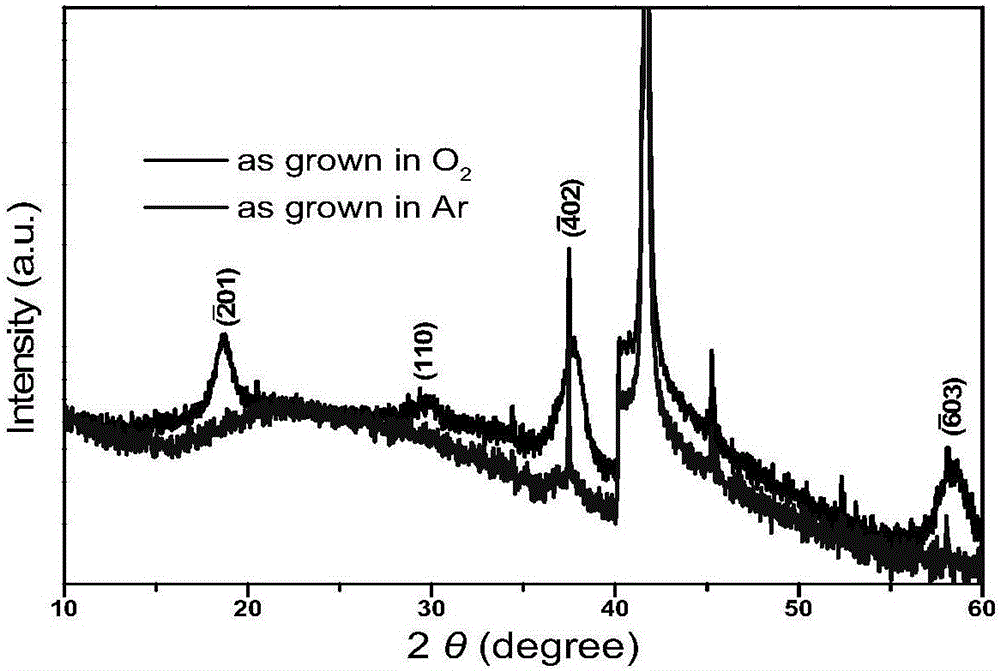

[0030] 3) Ga 2 o 3 Thin film deposition process: first vacuumize the chamber, heat the n-type Si substrate, and then pass in argon gas to adjust the pressure in the vacuum chamber; the heating temperature of the n-type Si substrate is 700°C, and the The degree of ionization is 1.0×10 -4 Pa, the adjusted pressure of the vacuum chamber is 1Pa, Ga 2 o 3 The distance between the target and the n-type Si substrate is set to 5 cm, the sputtering pow...

Embodiment 2

[0035] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), first vacuumize the cavity, heat the n-type Si substrate, and then pass in argon gas to adjust the pressure in the vacuum cavity; wherein, the heating temperature of the n-type Si substrate is 700°C, and after the cavity is evacuated The degree of ionization is 1.0×10 -4 Pa, the adjusted pressure of the vacuum chamber is 2Pa, Ga 2 o 3 The distance between the target and the n-type Si substrate was set at 5 cm, the sputtering power was 70 W, and the deposition time was 1 hour.

[0036] Gained Ga 2 o 3 The chemical composition and morphology of the film are similar to Example 1. A voltage is applied across the interdigitated electrode of a new type of gallium oxide thin-film flame detector for photoelectric performance measurement. The maximum voltage applied for V-I measurement is 2 volts, and the I-t curve is measured at a voltage of 0.5 volts. It is found that the control of the ultraviolet lamp...

Embodiment 3

[0038] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), first vacuumize the cavity, heat the n-type Si substrate, and then pass in argon gas to adjust the pressure in the vacuum cavity; wherein, the heating temperature of the n-type Si substrate is 700°C, and after the cavity is evacuated The degree of ionization is 1.0×10 -4 Pa, the adjusted pressure of the vacuum chamber is 1Pa, Ga 2 o 3 The distance between the target and the n-type Si substrate was set at 5 cm, the sputtering power was 70 W, and the deposition time was 2 hours.

[0039] Gained Ga 2 o 3 The chemical composition and morphology of the film are similar to Example 1. A voltage is applied across the interdigitated electrode of a new type of gallium oxide thin-film flame detector for photoelectric performance measurement. The maximum voltage applied for V-I measurement is 2 volts, and the I-t curve is measured at a voltage of 0.5 volts. It is found that the control of the ultraviolet lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Interdigital spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com