Single-sided light emission light emitting element and production method thereof

A technology for light-emitting components and single-sided light emission, which is applied to electrical components, semiconductor devices, circuits, etc., can solve problems such as abnormal module performance and appearance, and low design flexibility, so as to achieve improved photoelectric characteristics, good competitive advantages, and light emission direction strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

1 example 1

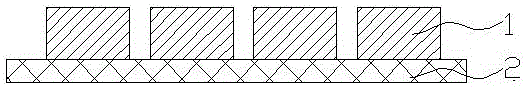

[0026] 1. Fix a plurality of light-emitting diodes 1 on the same surface of the fixing film 2 in an array with equal row and column spacing. Such as figure 1 Shown.

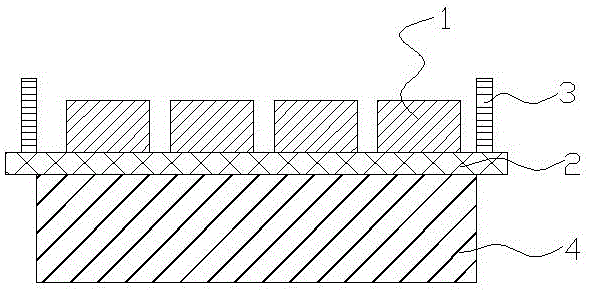

[0027] 2. Position the fixed film 2 tightly on the carrier 4 through the clamp 3, and make each light-emitting diode 1 face upwards, such as figure 2 Shown.

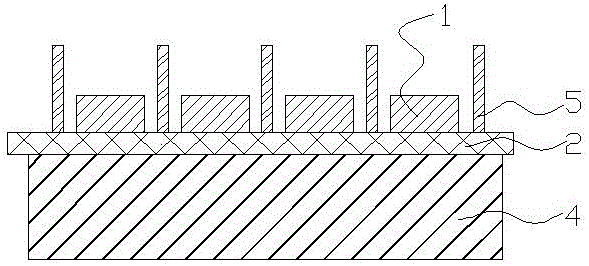

[0028] 3. Fix the steel mesh 5 on the fixing film 2, and use optical positioning components to make the light-emitting diodes 1 in the middle of each mesh of the steel mesh 5 one by one. Note: The mesh depth of the steel mesh 5 is slightly larger than the thickness of the light emitting diode 1. Such as image 3 Shown.

[0029] Use a spatula to fill the reflective glue 6 in each mesh of the steel mesh 5, such as Figure 4 Shown. After the reflective adhesive 6 is dried, it is separated from the steel mesh 5, and the reflective adhesive on the light-emitting surface of the light-emitting diode 1 is removed by grinding to obtain a semi-product such as Figure 5...

2 example 2

[0037] Others are similar, except that when designing the steel mesh 5, the mesh is designed into a bell mouth shape with an upper surface area larger than a lower surface area.

[0038] As a result, products such as Picture 8 Shown:

[0039] Two electrodes 8 are arranged on the bottom surface of the light-emitting diode 1, a phosphor glue layer 7 is arranged on the front surface of the light-emitting diode 1, and a reflective glue layer 6 is arranged on all four sides of the light-emitting diode 1.

[0040] The thickness of the reflective adhesive layer 6 close to the bottom surface is thinner than that close to the front surface.

[0041] The phosphor glue layer 7 may also be formed by multiple phosphor glue layers with different refractive indexes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com