Determination method of chromium elements, nickel elements, arsenic elements, selenium elements, cadmium elements and lead elements in Snus

A determination method and technology of snus, which is applied to the determination of arsenic, chromium, nickel, lead elements in snus, cadmium and selenium, and can solve the problems that the determination cannot be realized at the same time and the processing operation is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Measurement method

[0059] 1.1 Sample pretreatment

[0060] Accurately weigh the snus sample and place it in a microwave digestion tank with an accuracy of 0.1 mg, and then add the digestion agent into the microwave digestion tank. Wherein, the solid-liquid ratio of the added weight of the snus sample to the added volume of the digestion agent is: 0.03-0.15:1 (g / ml). The digestion agent is a mixed aqueous solution of nitric acid, hydrogen peroxide and hydrofluoric acid, specifically 5-12ml60-65% nitric acid, 2-6ml20-30% hydrogen peroxide, 1ml30-40% hydrofluoric acid, preferably 5- 10ml65% nitric acid, 2-4ml30% hydrogen peroxide, 1ml40% hydrofluoric acid. Seal the digestion tank and place it in a microwave digestion instrument.

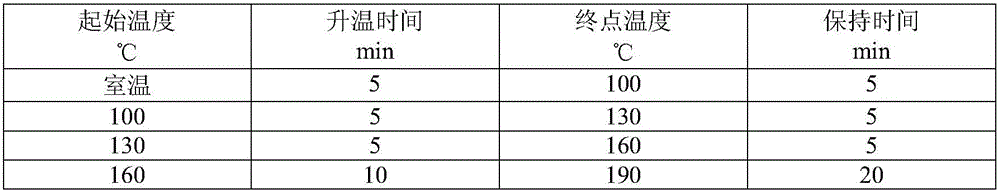

[0061] Set the heating program for the microwave digestion method, specifically: the initial temperature is room temperature (20-25°C), rise to 90-110°C with a heating time of 4-6min, and keep for 4-6min; then use a heating time of 4-6min...

Embodiment 2

[0075] 1. Measurement method

[0076] 1.1 Sample pretreatment

[0077] Accurately weigh the snus sample and place it in a microwave digestion tank with an accuracy of 0.1 mg, and then add the digestion agent into the microwave digestion tank. Wherein, the solid-liquid ratio of the added weight of the snus sample to the added volume of the digestion agent is: 0.04-0.07:1 (g / ml). The digestion agent is a mixed aqueous solution of nitric acid, hydrogen peroxide, and hydrofluoric acid, specifically 5ml of 65% nitric acid, 2ml of 30% hydrogen peroxide, and 0.5ml of 40% hydrofluoric acid, which are placed in a microwave digestion apparatus.

[0078] Set the heating program for the microwave digestion method, specifically: the initial temperature is room temperature (20-25°C), and the temperature is raised to 100°C with a heating time of 5 minutes, and kept for 5 minutes; then raised to 130°C with a heating time of 5 minutes, and kept for 5 minutes; Then raise the temperature to 16...

Embodiment 3

[0096] 1. Results and discussion

[0097] 1.1 Selection of digestion solution

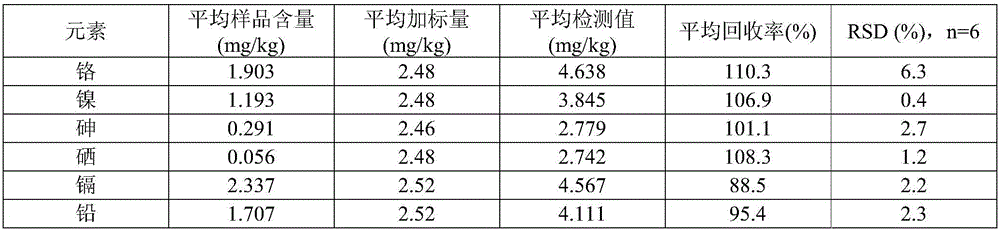

[0098] Add snus samples to the blank solution, respectively choose digestion agent 1: 65% nitric acid, 30% hydrogen peroxide, 40% hydrofluoric acid (volume ratio is 10:4:1); digestion agent 2: 65% nitric acid , 30% hydrogen peroxide (volume ratio 5:2); digestion agent 3: 65% nitric acid, 30% hydrogen peroxide, 35% hydrochloric acid (volume ratio 5:2:1). Perform microwave digestion according to the conditions specified in 1.1 of Example 2, and cool, transfer, and constant volume to obtain a sample solution. At the same time, a blank experiment was carried out according to the conditions specified in 1.1 of Example 2 to obtain a blank solution. According to the standard solution and the internal standard solution of 1.2 in Example 2, finally use ICP-MS to detect respectively. From the comparison in Table 4, it can be seen that when the digestion agent 1 is selected, the detection results of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com