Er<3+>/Pr<3+> co-doped Na5Lu9F32 monocrystal and growth method thereof

A growth method and single crystal technology, applied in the field of Na5Lu9F32 single crystals, can solve problems such as unfavorable large-scale production of fluoride single crystals, affecting crystal quality, etc., and achieve the effects of simple equipment and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

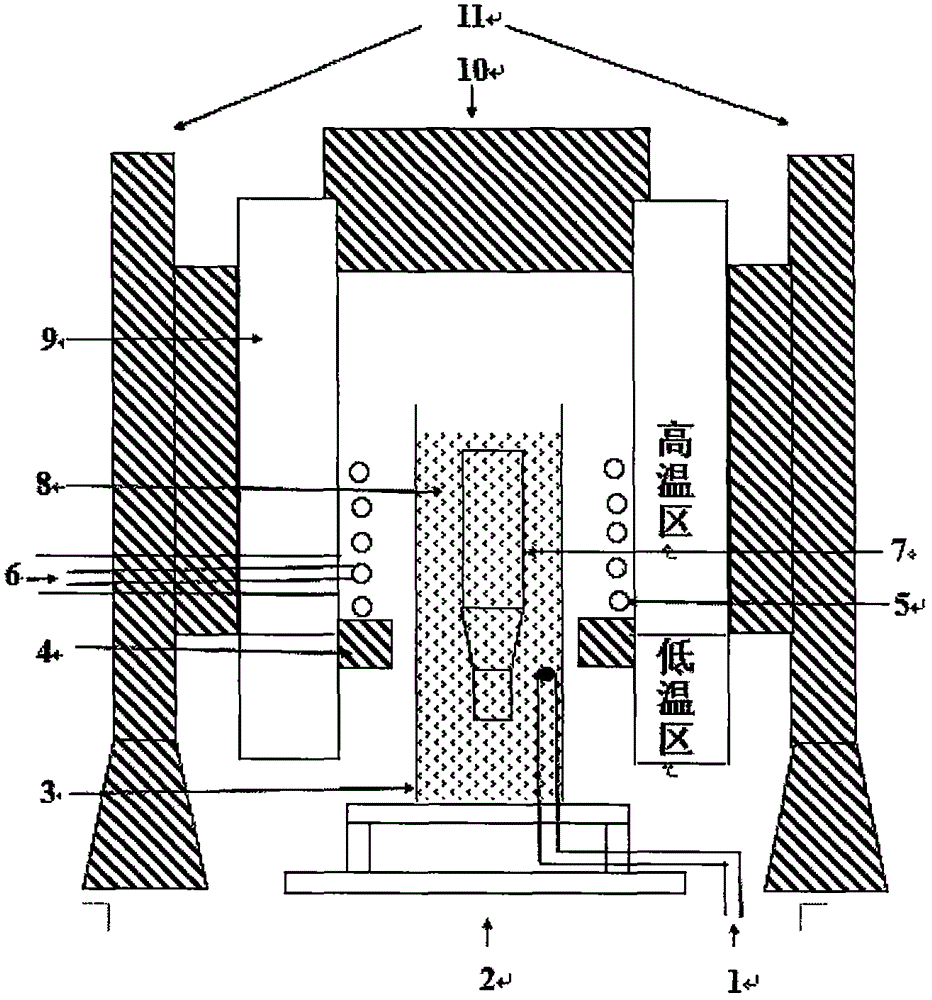

Method used

Image

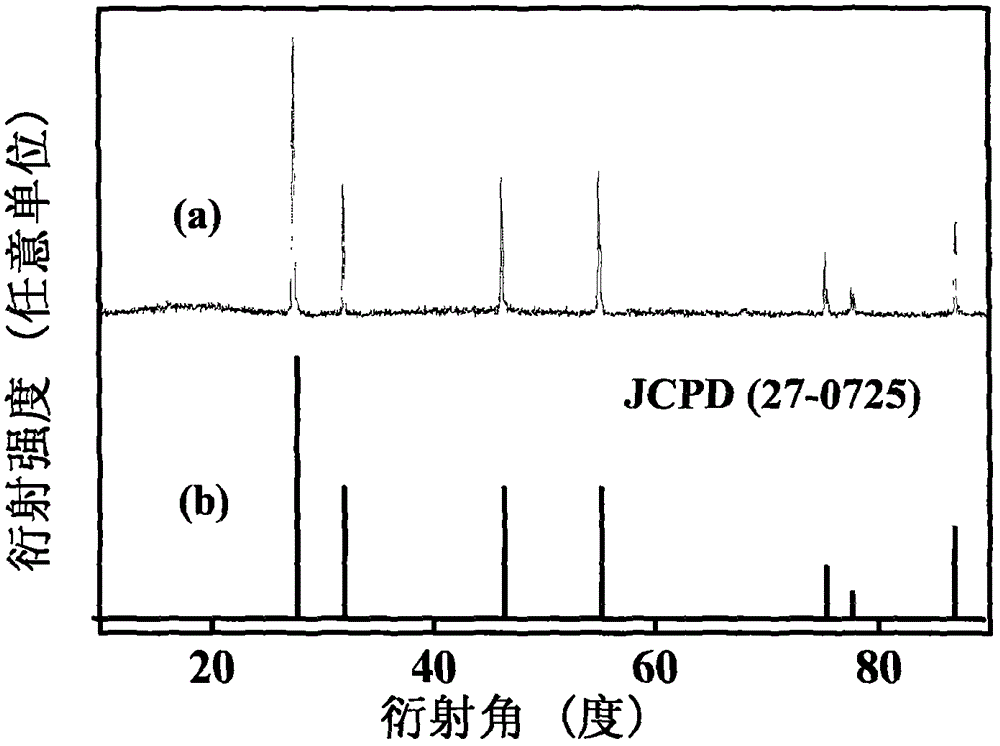

Examples

Embodiment 1

[0035] A rare earth ion doped Na 5 Lu 9 f 32 A method for growing a single crystal, comprising the following specific steps:

[0036] (1), according to the following composition: 40mol% NaF, 59.31mol% LuF 3 , 0.66mol% ErF 3, 0.03mol% PrF 3 , weighing a total amount of 150 grams of each preparation raw material with a purity greater than 99.99%, placing them in a mill after mixing, and milling and mixing for 5 hours to obtain a uniform powder;

[0037] (2), the above-mentioned mixture is placed in the boat-shaped platinum crucible, and then installed in the platinum pipeline of the tubular resistance furnace, and then firstly use N 2 Remove the air in the platinum pipe with gas, and then conduct reaction treatment for 5 hours at a temperature of 770°C under HF gas. 2 Gas cleaning the residual HF gas in the pipeline to obtain polycrystalline powder;

[0038] (3), the above-mentioned polycrystalline powder is placed in a grinder and ground into powder, then placed in a Pt ...

Embodiment 2

[0047] It is basically the same as Example 1, except that the raw materials in step (1) are composed according to the following proportions: 40mol% NaF, 56.42mol% LuF 3 , 3.3mol% ErF 3 , 0.28mol% PrF 3 , placed in a mill after mixing, milling and mixing for 6 hours; in the step (2), at a temperature of 800 ° C, under HF gas, the reaction treatment was carried out for 1 hour; the parameters for growing crystals in the step (4) were: furnace body temperature is 1020°C, the inoculation temperature is 880°C, the temperature gradient of the solid-liquid interface is 80°C / cm, and the upward movement speed of the thermal field is 2mm / h; in step (5), the furnace temperature is lowered to room temperature at 50°C per hour, and finally Er 3+ / Pr 3+ double doped Na 5 Lu 9 f 32 single crystal.

Embodiment 3

[0052] It is basically the same as Example 1, except that the raw materials in step (1) are composed according to the following proportions: 40mol% NaF, 57.77mol% LuF 3 , 2.1mol% ErF 3 , 0.13mol% PrF 3, placed in a mill after mixing, milling and mixing for 5.5 hours; in step (2), at a temperature of 780 ° C, under HF gas, the reaction treatment was carried out for 3 hours; the parameters for growing crystals in step (4) were: furnace body temperature The inoculation temperature is 1010°C, the inoculation temperature is 870°C, the temperature gradient of the solid-liquid interface is 60°C / cm, and the upward movement speed of the thermal field is 1.2mm / h; in step (5), the furnace temperature is lowered to room temperature at 30°C per hour, and finally get Er 3+ / Nd 3+ double doped Na 5 Lu 9 f 32 single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com