Device and method for treating methanol-to-olefin waste alkali solution

A technology for methanol to olefins and treatment devices, which is applied in multi-stage water treatment, aerobic process treatment, natural water treatment and other directions, can solve the problems of high requirements on equipment material and safety performance, low organic matter removal efficiency, and large equipment investment scale. , to achieve the effect of reducing one-time investment and comprehensive processing cost of system operation, simple structure, low equipment investment and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

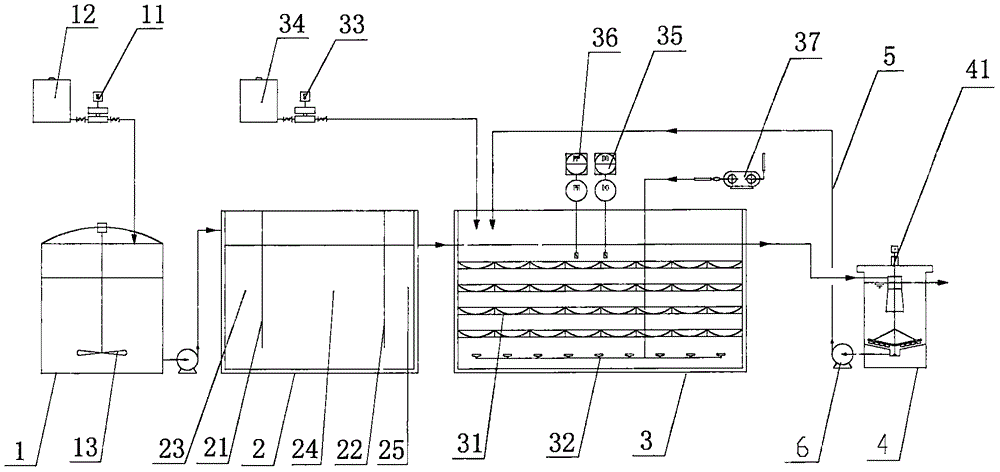

[0025] A treatment device for methanol-to-olefin waste lye of the present invention comprises a pH adjustment tank 1, a grease trap 2, a bioreactor 3, and a sedimentation tank 4 connected in sequence through pipelines, and the sedimentation tank 4 and the bioreactor 3 pass through the sewage Mud return pipe 5 is connected. The spent lye from methanol to olefins passes through the pH adjustment tank 1, the grease trap 2, the bioreactor 3 and the sedimentation tank 4 in sequence. 2 Remove slick oil and polymers in the waste caustic; decompose the pollutants in the waste caustic in the bioreactor 3, separate the sludge and waste water in the sedimentation tank 4, and return the sludge to the biological reaction device 3.

[0026] The pH adjustment tank 1 is connected with the concentrated sulfuric acid tank 12 through the concentrated sulfuric acid dosing metering pump 11, and a stirrer 13 is installed in the pH adjustment tank. In the pH adjustment tank 1, sulfuric acid is add...

Embodiment 2

[0032] Waste lye produced by a methanol-to-olefins plant, wherein: COD is 10,000 mg / l, sodium carbonate concentration is 10.2wt%, and sodium hydroxide concentration is 1.5wt%. In organic pollution, the concentration of phenol is 55mg / l, methanol concentration is 270mg / l, benzene is 18mg / l, ethylbenzene is 6mg / l, toluene is 3mg / l, dimethyl ether is 0.8mg / l, ethyl ketone is 25mg / l, methyl ethyl ketone is 0.08mg / l , Ammonia nitrogen 48mg / l. Adopt the method of the present invention to process, the inventive method comprises the following steps:

[0033] (1) pump the spent lye into the pH adjustment tank, add concentrated sulfuric acid to adjust the pH of the spent lye to 5.8;

[0034] (2) the waste lye after pH adjustment is carried out oil separation treatment in the grease trap, removes slick oil and polymer; The residence time of waste lye in the grease trap is 0.5h;

[0035] (3) The waste lye after the oil separation treatment enters the bioreactor, and the salt-tolerant mi...

Embodiment 3

[0039] The waste lye produced by the methanol-to-olefins unit, wherein: COD is 8000mg / l, sodium carbonate concentration is 10wt%, sodium hydroxide concentration is 1.2wt%, phenol concentration in organic pollution is 50mg / l, methanol concentration is 260mg / l, benzene 15mg / l, ethylbenzene 5mg / l, toluene 2mg / l, dimethyl ether 1mg / l, ethyl ketone 30mg / l, methyl ethyl ketone 0.1mg / l, ammonia nitrogen 50mg / l. Adopt the method of the present invention to process, the inventive method comprises the following steps:

[0040] (1) pump the spent lye into the pH adjustment tank, add concentrated sulfuric acid to adjust the pH of the spent lye to 6.1;

[0041] (2) the waste lye after the pH adjustment is carried out in the grease trap to remove oil slicks and polymers; the residence time of the waste lye in the grease trap is 1.0h;

[0042] (3) The waste lye after the oil separation treatment enters the bioreactor, and the salt-tolerant microorganisms in the bioreactor are used to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com