A kind of preparation method of bulk nitrogen-containing multi-level porous carbon material

A carbon material and block technology, which is applied in the preparation of new heteroatom-doped carbon materials and their electrode applications, can solve problems such as complex process routes, complex powder structure molding processes, and high processing conditions, and achieve good application prospects , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Get 1ml tetraethyl orthosilicate (TEOS) and dissolve in 3ml DMF, stir to obtain colorless transparent solution, meanwhile, prepare 125g L -1 Add 1.5ml of polyacrylonitrile-DMF solution, and add it into TEOS-DMF solution, stir well. Add 0.01728 g of 1,6-hexanediamine solution (the solvent is ethanol and water at 1:1) while stirring at 80°C, and stir evenly. The reaction system was sealed, turned to 90°C for aging for 12 hours, and dried to obtain a block polymer. And put it under the protection of inert atmosphere, 3°C min -1 Raise the temperature to 400°C, keep the temperature constant for 60 minutes, then raise the temperature to 800°C at the same heating rate, and keep the temperature constant for 120 minutes to obtain a bulk carbon-silicon oxide composite with shape retention. Use 8% sodium hydroxide solution in water and ethanol (3:1 volume ratio) to remove silicon at 50°C for 24h, then wash with water and dry at 90°C for 24h.

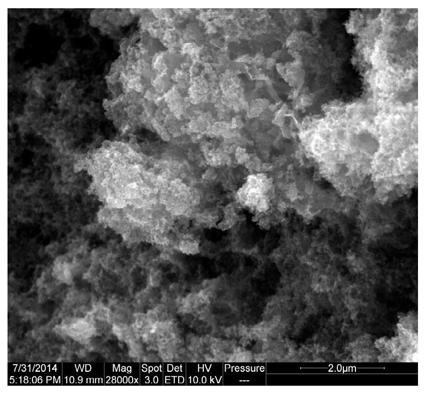

[0026] The scanning electron micro...

Embodiment 2

[0028] Get 1.2ml tetraethyl orthosilicate (TEOS) and dissolve in 3ml DMF, stir to obtain a colorless transparent solution, meanwhile, prepare 100g L -1Add 5ml of polyacrylonitrile-DMF solution, and add it into TEOS-DMF solution, stir evenly. Add 800ul NH 3 .H 2 O, stir well. Seal the reaction system, transfer it to a certain temperature for aging for 12 hours, and after natural cooling, perform solvent replacement (3 times with ethanol, 3 times with n-hexane and 3 times with trimethylchlorosilane), and dry at 50°C to obtain block polymerization things. And put it under the protection of inert atmosphere, 3 ℃ min -1 Raise the temperature to 400°C, keep the temperature constant for 60 minutes, then raise the temperature to 800°C at the same heating rate, and keep the temperature constant for 120 minutes to obtain a bulk carbon-silicon oxide composite with shape retention. Use 8% sodium hydroxide solution in water and ethanol (3:1 volume ratio) to remove silicon at 50°C for ...

Embodiment 3

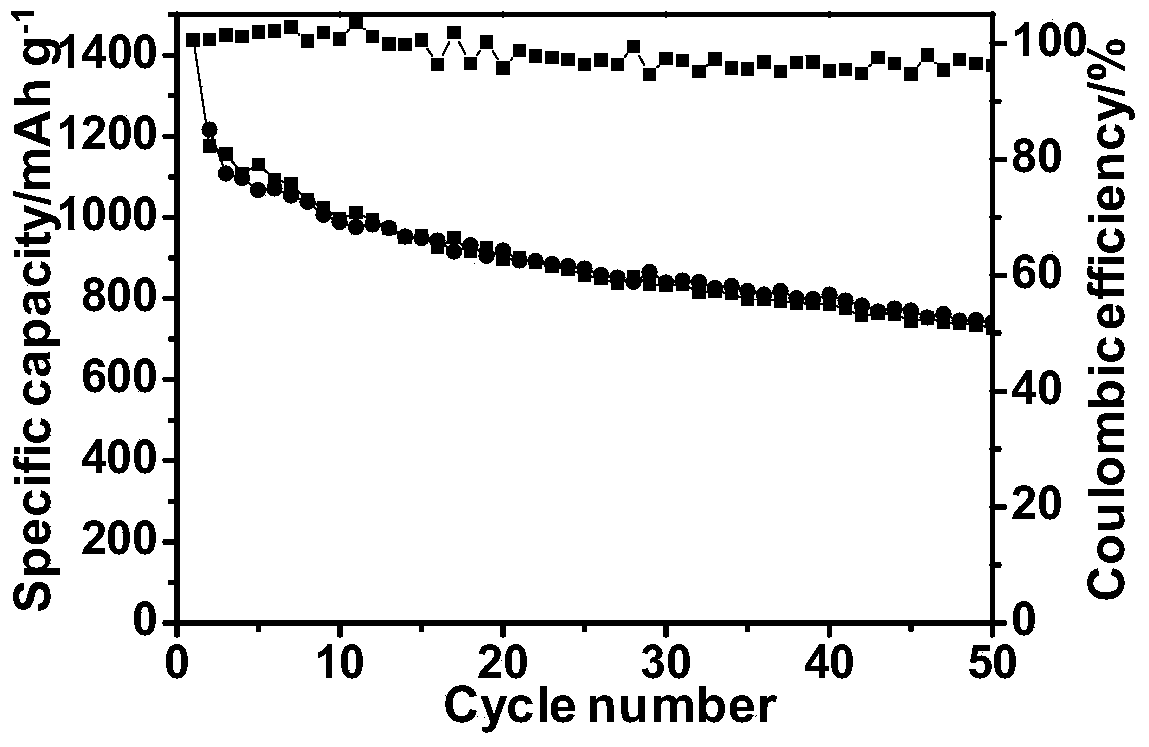

[0030] Taking the bulk nitrogen-containing porous carbon prepared in Example 1, a carbon-sulfur composite with a sulfur content of 44% was prepared. Grind the carbon-sulfur composite, acetylene black, and PVDF at a mass ratio of 8:1:1, add an appropriate amount of N-methylpyrrolidone, mix well, and coat the aluminum foil to prepare a pole piece. The electrode sheet (size 1cm×1cm, about 25-50μm thick, containing 0.5-1.5mg of sulfur) was used as the positive electrode, and the lithium sheet was used as the negative electrode to assemble a button battery, and its electric capacity at a rate current density of 0.1C was tested. chemical properties. image 3 is the electrochemical cycling stability curve of the material. The first discharge specific capacity is 1400mAh g -1 , the specific capacity reached 750mAh g after 50 cycles at a current density of 0.1C -1 Above, has good cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| macropore | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com