Probiotics toothpaste composition capable of improving health of oral cavity

A technology of probiotics and compositions, applied in the field of probiotics toothpaste compositions, can solve the problems of reduced effect of oral care products, inattentiveness to the growth and reproduction of probiotics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

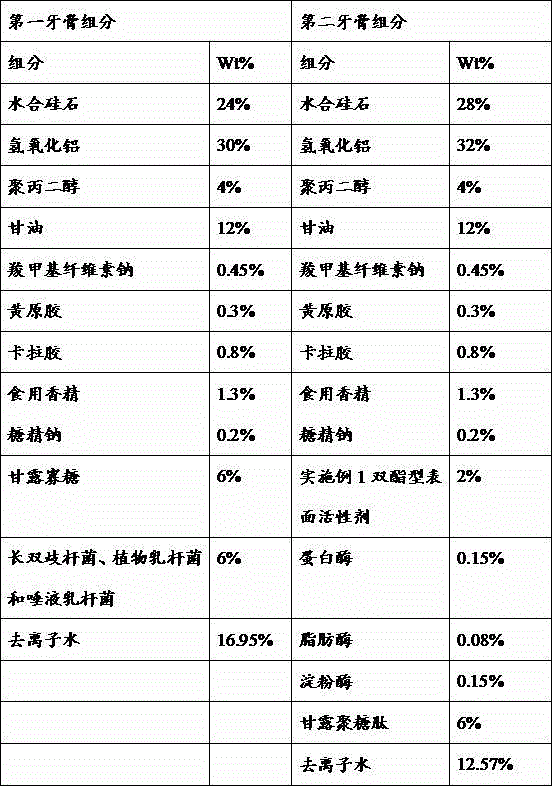

Examples

Embodiment 1

[0056] In a 10-liter esterification reaction kettle with a condenser and a water separator, 5 kg of toluene and 4.48 kg of linear octylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=8, n= 210), 0.52 kg of phthalic anhydride, stirred at a stirring speed of 150 rpm for 30 minutes to make linear octylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=8, n=210) and phthalic anhydride are fully dissolved in toluene; then add 0.05 kg of p-toluenesulfonic acid, and stir at a stirring speed of 150 rpm for 10 minutes, p-toluenesulfonic acid catalyzes linear octylphenol polyoxygen Ethyl ether (alkylphenol polyoxyethylene ether, R=8, n=210) undergoes an esterification reaction with phthalic anhydride; heat up to 110°C, stir at a stirring speed of 150 rpm, and reflux for 4 hours; Finally remove the water in the water separator, utilize the vacuum pump to remove toluene, cool to room temperature, obtain the diester surfactant, and the diester surfactant ...

Embodiment 2

[0060] In a 10-liter esterification reaction kettle with a condenser and a water separator, 5 kg of toluene and 4.92 kg of isooctylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=12, n=500 ), 0.08 kg of phthalic anhydride, and stirred at a stirring speed of 150 rpm for 30 minutes to make isooctylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=12, n=500) and o- Fully dissolve phthalic anhydride in toluene; add 0.003 kg of phosphoric acid, and stir for 10 minutes at a stirring speed of 150 rpm, phosphoric acid catalyzes isooctylphenol polyoxyethyl ether (alkylphenol polyoxyethylene ether, R=12 , n=500) and phthalic anhydride to undergo esterification reaction; heat up to 110°C, stir at a stirring speed of 150 rpm, and reflux for 4 hours; finally remove the water in the water separator and use a vacuum pump to remove Toluene is cooled to room temperature to obtain the diester surfactant, and the diester surfactant structure is as follows:

...

Embodiment 3

[0064] In a 10-liter esterification reaction kettle with a condenser and a water separator, 5 kilograms of toluene and 4.85 kilograms of linear dodecylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=18, n=360), 0.15 kg of phthalic anhydride, stirred at a stirring speed of 150 rpm for 30 minutes to make linear dodecylphenol polyoxyethylene ether (alkylphenol polyoxyethylene ether, R=18, n=360) and phthalic anhydride are fully dissolved in toluene; then add 0.02 kg of benzenesulfonic acid, and stir at a stirring speed of 150 rpm for 10 minutes, benzenesulfonic acid catalyzes the linear dodecylphenol polyoxygen Ethyl ether (alkylphenol polyoxyethylene ether, R=18, n=360) undergoes an esterification reaction with phthalic anhydride; heat up to 110°C, stir at a stirring speed of 150 rpm, and reflux for 4 hours; Finally remove the water in the water separator, utilize the vacuum pump to remove toluene, cool to room temperature, obtain the diester surfactant, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com