Manufacturing method of PCB, and PCB

A manufacturing method and a technology for protecting cover plates, which are applied in the fields of printed circuit manufacturing, components of lighting devices, lighting and heating equipment, etc., can solve complex processes, large equipment space, and inability to achieve higher density and high integration LED packaging, etc. problems, to achieve the effect of improving alignment accuracy, improving pass rate and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

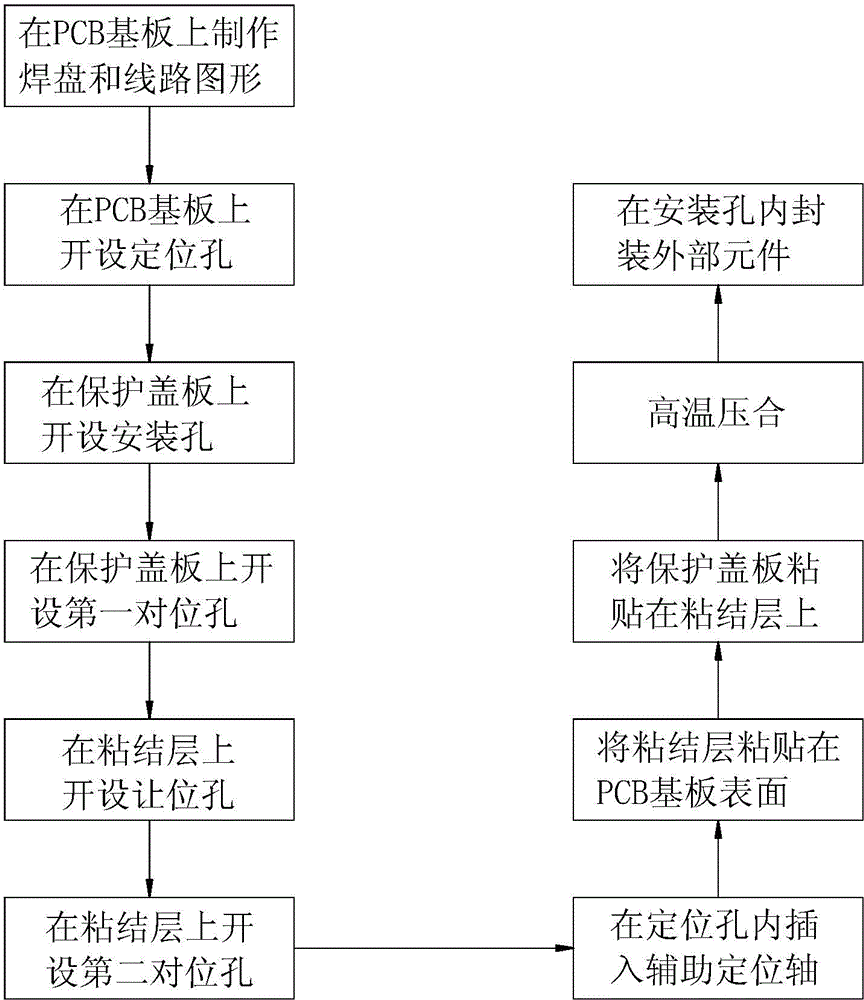

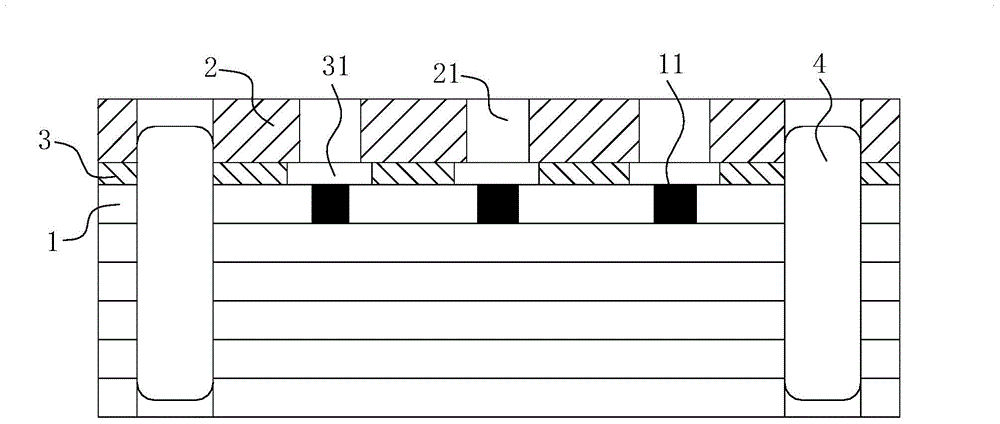

[0088] Such as Figures 1 to 8 As shown, on the one hand, a method for manufacturing a PCB is provided, comprising the following steps:

[0089] S10 , providing a PCB substrate 1 , and making pads 11 and circuit patterns on the surface of the PCB substrate 1 . In this embodiment, the PCB substrate 1 is a multilayer PCB substrate made of high-strength substrate materials.

[0090] S20 , making a solder resist layer on the surface of the PCB substrate 1 , the solder resist layer is a black solder resist layer.

[0091] S30 , fabricating an electroless nickel gold layer or an electroplated gold layer on the surface of the PCB substrate 1 .

[0092] S40 , opening a positioning hole 12 on the PCB substrate 1 .

[0093] S50 , performing wet electroplating on the positioning hole 12 to improve the wear resistance of the positioning hole 12 .

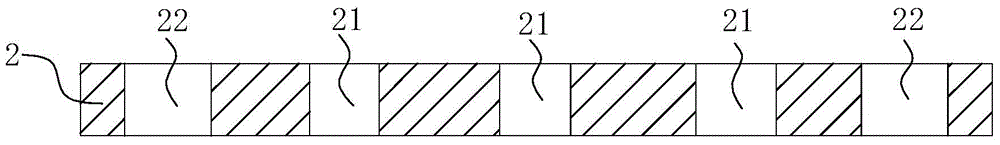

[0094] S60 , providing a protective cover 2 , and opening mounting holes 21 on the protective cover 2 for the pads 11 on the surface of th...

Embodiment 2

[0113] Such as Figures 1 to 5 shown, and as Figures 9 to 11 As shown, on the one hand, a method for manufacturing a PCB is provided, comprising the following steps:

[0114] S10 , providing a PCB substrate 1 , and making pads 11 and circuit patterns on the surface of the PCB substrate 1 . In this embodiment, the PCB substrate 1 is a single-sided PCB substrate 1 made of high-strength substrate material.

[0115] S20 , making a solder resist layer on the surface of the PCB substrate 1 , the solder resist layer is a white solder resist layer.

[0116] S30 , fabricating an electroless nickel gold layer or an electroplated gold layer on the surface of the PCB substrate 1 .

[0117] S40 , opening a positioning hole 12 on the PCB substrate 1 .

[0118] S50 , performing wet electroplating on the positioning hole 12 to improve the wear resistance of the positioning hole 12 .

[0119] S60 , providing a protective cover 2 , and opening mounting holes 21 on the protective cover 2 f...

Embodiment 3

[0138] Such as Figures 1 to 5 shown, and as Figures 9 to 11As shown, on the one hand, a method for manufacturing a PCB is provided, comprising the following steps:

[0139] S10 , providing a PCB substrate 1 , and making pads 11 and circuit patterns on the surface of the PCB substrate 1 . In this embodiment, the PCB substrate 1 is a double-sided PCB substrate 1 made of high-strength substrate material.

[0140] S20 , making a solder resist layer on the surface of the PCB substrate 1 , the solder resist layer is a white solder resist layer.

[0141] S30 , fabricating an electroless nickel gold layer or an electroplated gold layer on the surface of the PCB substrate 1 .

[0142] S40 , opening a positioning hole 12 on the PCB substrate 1 .

[0143] S50 , performing wet electroplating on the positioning hole 12 to improve the wear resistance of the positioning hole 12 .

[0144] S60 , providing a protective cover 2 , and opening mounting holes 21 on the protective cover 2 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com