A kind of preparation method of improved avibactam sodium intermediate compound

A compound and volume ratio technology, applied in the field of medicinal chemistry, can solve the problems of unsuitability for industrial scale-up production, cumbersome reaction operation process, and high risk of hydrogen reduction, so as to avoid hydrogenation catalytic operation, reduce safety risks, improve product yield and The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

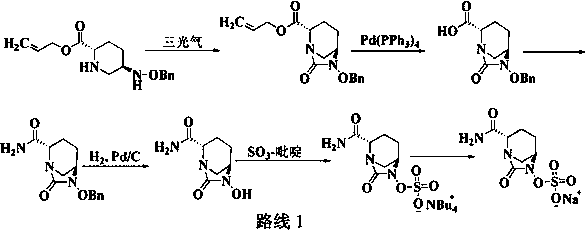

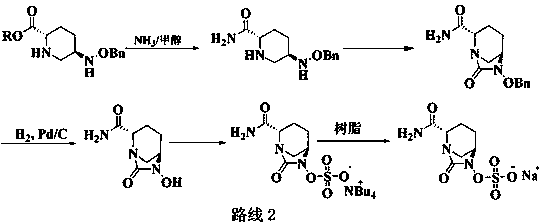

Problems solved by technology

Method used

Image

Examples

Embodiment 1

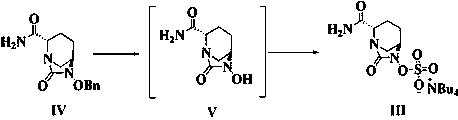

[0033] Example 1, ({[(2S,5R)-2-carbamoyl-7-oxo-6-(sulfooxy)-1,6-diazabicyclo[3, Preparation of 2,1]-oct-6-yl]oxy}sulfonyl)tetrabutylammonium salt (compound III)

[0034] Add isopropanol (650ml) and purified water (650ml) into the reaction flask, add compound IV (140.0g) and palladium carbon (14.0g), control the temperature at 5-15°C, add triethylsilane (139.0g) dropwise , TLC detects that the reaction is complete and then suction filtered and washed. Triethylamine (13.1 g) and trimethylamine sulfur trioxide (79.6 g) were added to the filtrate. The temperature was controlled at 5-15°C, and the reaction was stirred for 2 hours. A 45% aqueous solution of tetrabutylammonium hydroxide (235.0 g) was added. Dichloromethane was added to the reaction solution for extraction, dried over anhydrous sodium sulfate, filtered with suction, washed, and concentrated to obtain an oil. Add 700ml of methyl tert-butyl ether, stir and crystallize, filter with suction, wash, and dry to obtain ...

Embodiment 2

[0035] Example 2, ({[(2S,5R)-2-carbamoyl-7-oxo-6-(sulfooxy)-1,6-diazabicyclo[3, Preparation of 2,1]-oct-6-yl]oxy}sulfonyl)tetrabutylammonium salt (compound III)

[0036] Add ethanol (650ml) and purified water (650ml) into the reaction flask, add compound IV (140.0g) and palladium carbon (14.0g), control the temperature at 5-15°C, add dropwise triethylsilane (139.0g), TLC After the detection reaction is complete, filter with suction and wash. Triethylamine (13.1 g) and trimethylamine sulfur trioxide (79.6 g) were added to the filtrate. The temperature was controlled at 5-15°C, and the reaction was stirred for 2 hours. A 45% aqueous solution of tetrabutylammonium acetate (235.0 g) was added. Dichloromethane was added to the reaction solution for extraction, dried over anhydrous sodium sulfate, filtered with suction, washed, and concentrated to obtain an oil. Add 700ml of methyl tert-butyl ether, stir and crystallize, filter with suction, wash, and dry to obtain 230.0g of ...

Embodiment 3

[0037] Example 3, ({[(2S,5R)-2-carbamoyl-7-oxo-6-(sulfooxy)-1,6-diazabicyclo[3, Preparation of 2,1]-oct-6-yl]oxy}sulfonyl)tetrabutylammonium salt (compound III)

[0038] Add isopropanol (650ml) and purified water (650ml) into the reaction flask, add compound IV (140.0g) and palladium carbon (14.0g), control the temperature at 5-15°C, and add triethylsilane (139.0g) dropwise , TLC detected that the reaction was complete and then filtered and washed. Triethylamine (13.1 g) and trimethylamine sulfur trioxide (79.6 g) were added to the filtrate. The temperature was controlled at 5-15°C, and the reaction was stirred for 2 hours. A 45% aqueous solution of tetrabutylammonium acetate (235.0 g) was added. Dichloromethane was added to the reaction solution for extraction, dried over anhydrous sodium sulfate, filtered with suction, washed, and concentrated to obtain an oil. Add 700ml of methyl tert-butyl ether, stir and crystallize, filter with suction, wash, and dry to obtain 230...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com