Micro-reactor system with pulse diameter-variable microstructure

A technology of micro-reactor and micro-structure, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as high processing costs and complex structures, and achieve flexibility and convenient adjustment, reduce environmental impact, and achieve the effect of output upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

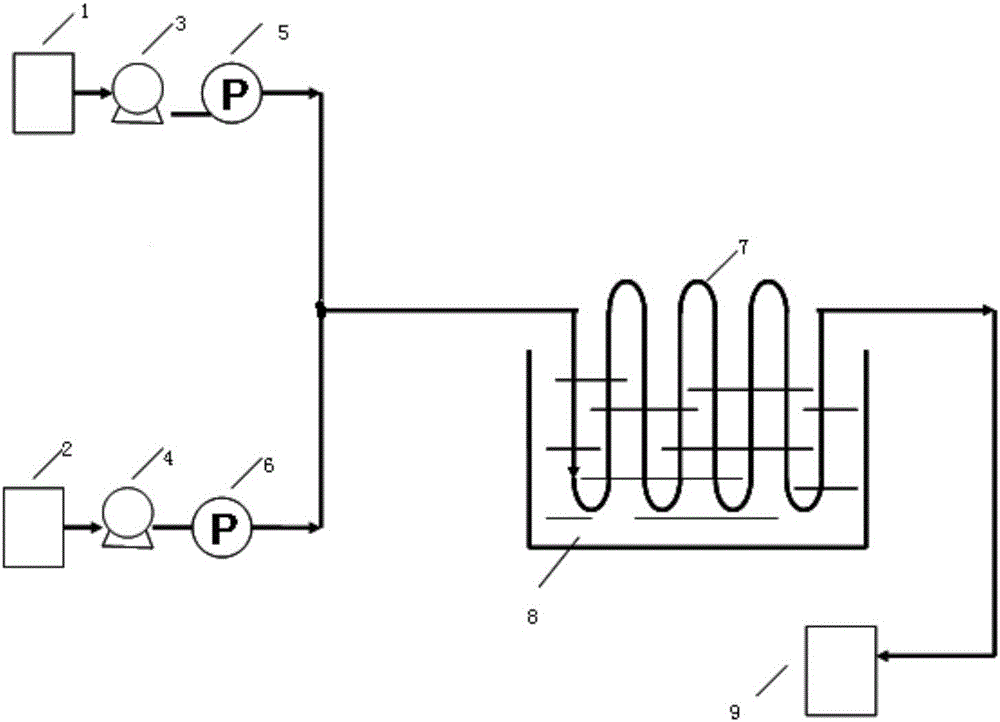

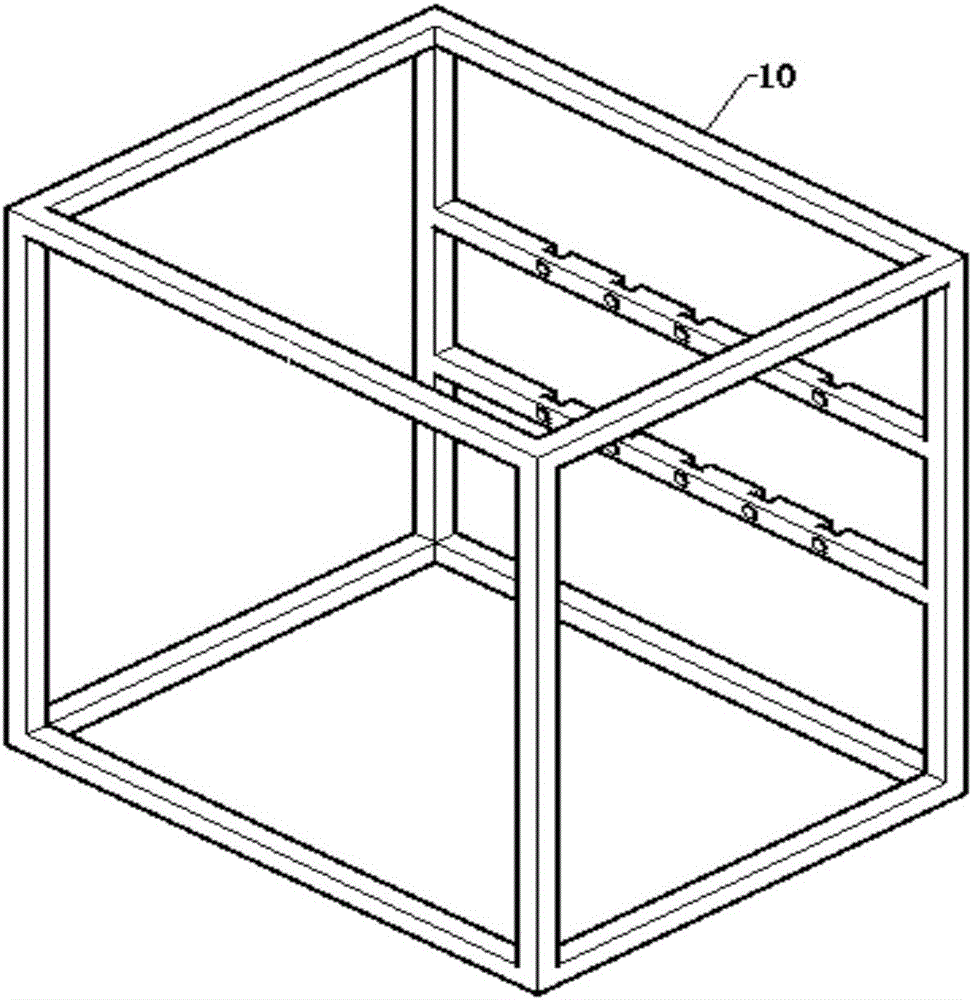

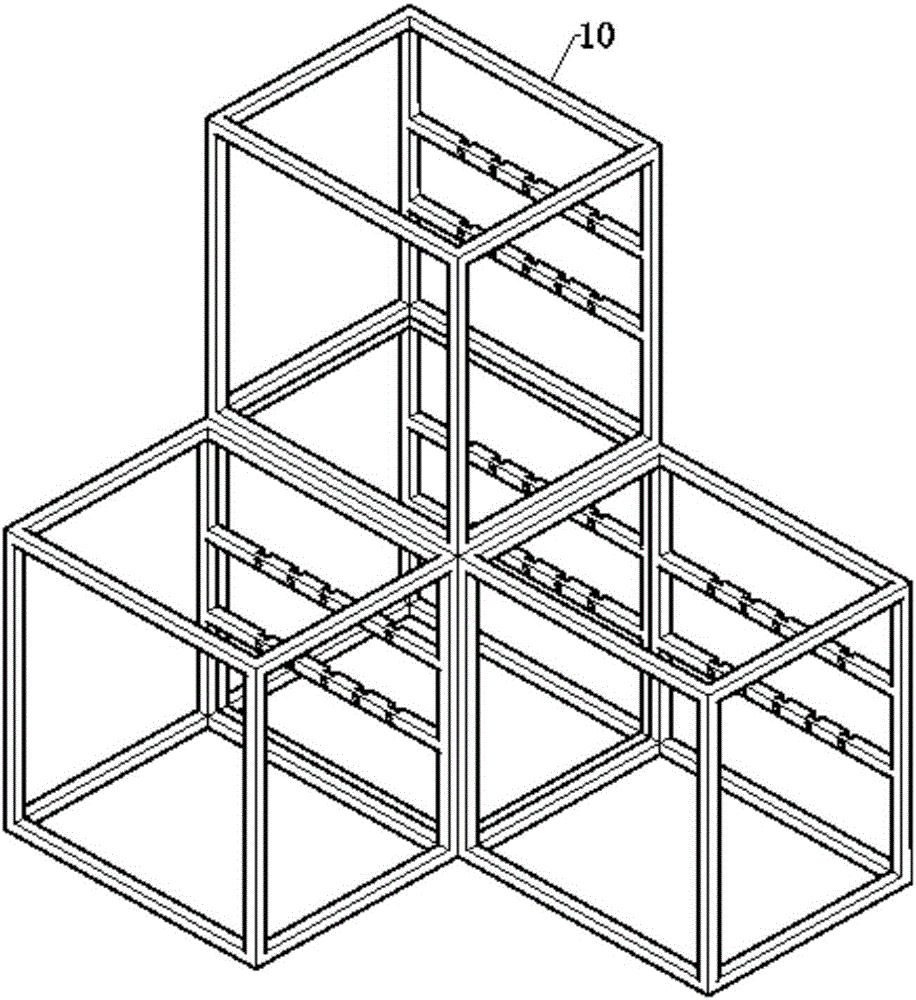

[0041] If microreactor system of the present invention is used to produce nitroguanidine product, concrete technological process is with reference to figure 1 , Image 6 with Figure 16 As shown, the raw material tanks (1, 2) are configured with different concentrations of guanidine nitrate aqueous solution and concentrated sulfuric acid. Set the flow control of the metering pump (3, 4), change the molar ratio of the aqueous solution of guanidine nitrate and concentrated sulfuric acid, control the flow rate and pressure of the aqueous solution of guanidine nitrate and concentrated sulfuric acid (5, 6), and pass the materials through the Y-type material fluid The feed inlet (11) is driven into the 316L stainless steel (SS316L) microchannel reactor system (7) with continuous pulse variable diameter microstructure (20, 30), and the reaction temperature is exchanged by the heat exchanger (8), and the heat conduction The liquid flows in through the heat exchanger inlet (15) and f...

Embodiment 2

[0043] The structure of the microchannel reactor in Example 2 is basically the same as that in Example 1, except that the material of the microchannel reactor in this example is Hastelloy (HC22 or HG35), the reaction temperature is 200°C, and the pressure is 2Mpa. The microchannel reaction system with continuous pulse variable-diameter microstructure provided by the patent of the present invention can operate the reactor in a wide range of pressure and temperature (the pressure can reach up to 10MPa, and the temperature range is -100~350℃), and it also has relatively Wide chemical corrosion resistance and wide chemical compatibility can be applied to many reaction types of nitrification, saponification, oxidation and hydrogenation. According to the different working conditions of the reaction type, the reactor module can be freely and flexibly combined into the designed reactor, and multi-step operations can be realized, such as premixing, preheating, material mixing, reactor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com