Dust filtering device used for 3D printing of selective laser melting and use method

A technology of laser selective melting and dust filtering device, which is applied in the direction of chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of powder reuse and multi-processing, harmful molding process, and change of component components, etc. The technical means are simple and easy Easy to operate, easy to use and maintain, and the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

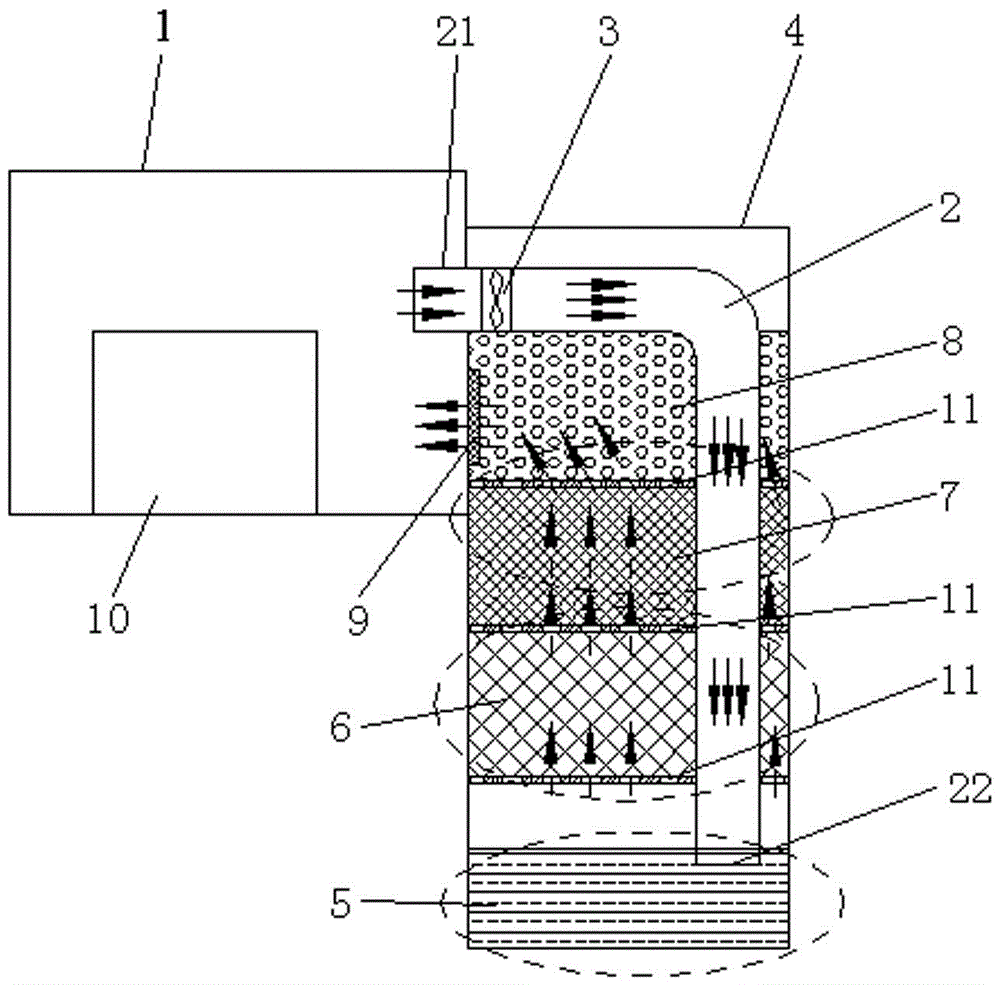

[0021] see figure 1 , a soot filter device for laser selective melting 3D printing, including a gas purification box 4 integrated with all filter device parts, the gas purification box 4 is sequentially provided with liquid filter media separated by porous partitions 11 from bottom to top Layer 5, coarse filter medium layer 6, fine filter medium layer 7 and desiccant layer 8, a suction pipe 2 runs through each layer, and the inlet 21 of the suction pipe 2 of the suction pipe 2 passes through the desiccant layer 8 Enter the molding chamber 1 of the laser selective melting 3D printing equipment, and place it obliquely above the molding platform 10, its outlet 22 is located in the liquid filter medium layer 5 and inserted about 0.2-8mm below the liquid surface, and the suction pipe 2 is provided with a The suction fan 3 that enters the air from the moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com