A kind of nylon fabric printing method based on polyamide copolymer

A polyamide copolymer and fabric printing technology, applied in the field of textile printing and dyeing, can solve the problems that acid dyes cannot be combined, have no thermal migration, and reduce the brightness of color, so as to improve the dyeing rate and the fixing rate, and it is not easy to stain. Color phenomenon, the effect of less dye floating color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

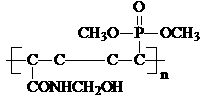

[0048] Mix 7.0g of N-methylolacrylamide, 20.0g of dimethyl vinylphosphonate, 1.2g of SP-80, 1.5g of sodium dodecylsulfonate and 60.3g of water, and stir well to form 90.0g of emulsion; 1.0g ammonium persulfate was dissolved in 9.0g water at room temperature, and fully stirred into 10.0g ammonium persulfate solution; half 45.0 g of the emulsion quality and half 5.0 g of the quality of ammonium persulfate solution were added to the reaction device of the three-necked flask, While heating and stirring, the temperature was raised to 70°C. When the temperature reaches 70°C, under stirring, slowly add the remaining emulsion and ammonium persulfate solution dropwise at the same time, and the dropping time is 120min. After the dropwise addition was completed, the stirring was continued for 120 min to obtain a polyamide copolymer A.

[0049] Mix 9.0g of N-methylolacrylamide, 16.0g of dimethyl vinylphosphonate, 1.5g of SP-80, 1.5g of sodium dodecylsulfonate and 62.0g of water, and stir...

Embodiment 1

[0053] 1) Add 2.0 g of polyamide copolymer A to 98.0 g of water, stir evenly to obtain solution A, then pad the nylon fabric with solution A, control the rolling rate to 85%, and place it on the drying equipment after padding is completed Drying, the drying temperature is 105°C;

[0054] 2) Mix 1.5g of H90 synthetic thickener, 0.6g of weak acid orange GS, 1.0g of acrylate prepolymer A and 96.9g of water, and fully stir until it becomes a slurry to prepare an orange phase printing paste;

[0055] 3) On the screen printing equipment, print the nylon fabric with the orange phase printing paste, after drying, and then steam it on the steamer equipment, the temperature is 100°C, the humidity is 100%, and the time is 15 minutes ;

[0056] 4) Wash the above steamed nylon fabric in a washing machine at a temperature of 50° C. for 15 minutes; then dry it in a conventional drying equipment to obtain an orange phase printed nylon fabric.

Embodiment 2

[0058] 1) Take 5.0 g of polyamide copolymer B, add 95.0 g of water, stir evenly to obtain solution B, then pad the nylon fabric with solution B, control the rolling rate to 85%, and place it on the drying equipment after padding is completed Drying, the drying temperature is 115°C;

[0059] 2) Mix 2.0g of PTF-A synthetic thickener, 2.5g of acid red 315, 1.5g of acrylate prepolymer B and 94.0g of water, and fully stir until it becomes a slurry to prepare a red phase printing paste;

[0060] 3) On the screen printing equipment, print the nylon fabric with the red phase printing paste, after drying, and then steam it on the steamer equipment, the temperature is 110°C, the humidity is 90%, and the time is 18 minutes ;

[0061] 4) Wash the above steamed nylon fabric in a washing machine at a temperature of 60° C. for 10 minutes; then dry it in a conventional drying equipment to obtain a red phase printed nylon fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com