Grinding aid for gold ore grinding with leaching assisting effect and preparation method therefor

A grinding aid and gold ore technology, which is applied in the direction of chemical instruments and methods, other chemical processes, process efficiency improvement, etc., can solve the problem that the grinding fineness cannot reach the designed fineness, increase the production load of equipment, tailings The problem of high gold grade running, to achieve the effect of reducing the amount of protective alkali, good grinding aid effect, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

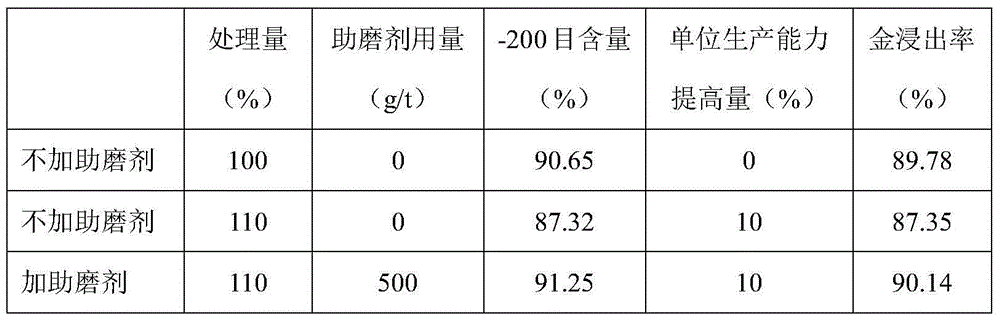

Embodiment 1

[0013] A grinding aid for gold ore grinding with leaching aid function,

[0014] Its components, by weight, include: CaO 2 10%, NaCl 30%, sodium tripolyphosphate 30%, sodium humate 30%, mix the components uniformly in proportion to get the grinding aid. Its dosage is 500g / t by weight, and it is directly added in solid form from the feed inlet of the ball mill.

[0015] An oxidized ore with a gold content of 4.25g / t. The metal minerals in the ore are mainly pyrite, followed by pyrrhotite and chalcopyrite, and a small amount of galena, sphalerite and limonite. Non-metallic minerals are mainly quartz, followed by potassium feldspar and plagioclase. The ore is of medium hardness.

[0016] Grinding adopts XMQ67 type 240×200 conical ball mill, steel ball filling rate is 35%, steel ball diameter and weight ratio are 26mm, 10%; 21mm, 15%; 18mm, 65%; 10mm, 10%; total weight 8Kg. The grinding concentration is 70%.

[0017] Cyanide leaching conditions: leaching pulp concentration 4...

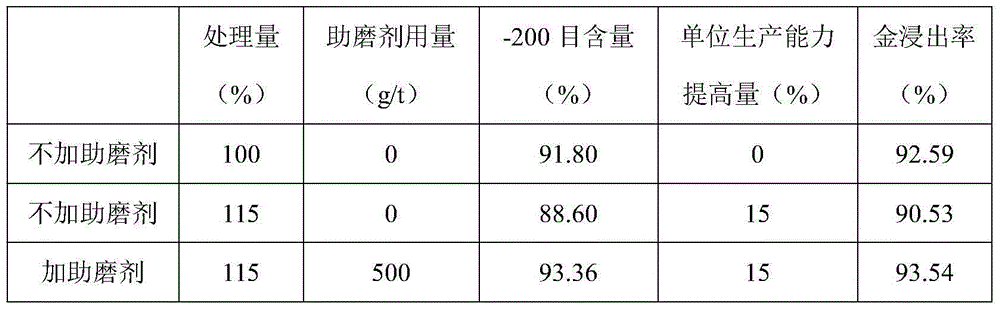

Embodiment 2

[0021] A grinding aid for gold ore grinding with leaching aid function,

[0022] Its components, by weight, include: CaO 2 20%, NaCl 20%, sodium tripolyphosphate 30%, sodium humate 30%, mix the components uniformly in proportion to get the grinding aid. Its dosage is 500g / t by weight, and it is directly added in solid form from the feed inlet of the ball mill.

[0023] An oxidized ore with a gold content of 1.95g / t. The metal minerals in the ore are mainly limonite and hematite, with a small amount of chalcopyrite and pyrite; the gangue minerals are mainly dolomite, calcite, quartz and mica. The ore is medium to soft in hardness.

[0024] Cyanide leaching conditions: leaching pulp concentration 40%, cyanide concentration 0.1%, cyanide leaching time 24 hours.

[0025] Grinding adopts XMQ67 type 240×200 conical ball mill, steel ball filling rate is 35%, steel ball diameter and weight ratio are 26mm, 10%; 21mm, 15%; 18mm, 65%; 10mm, 10%; total weight 8Kg. The grinding concen...

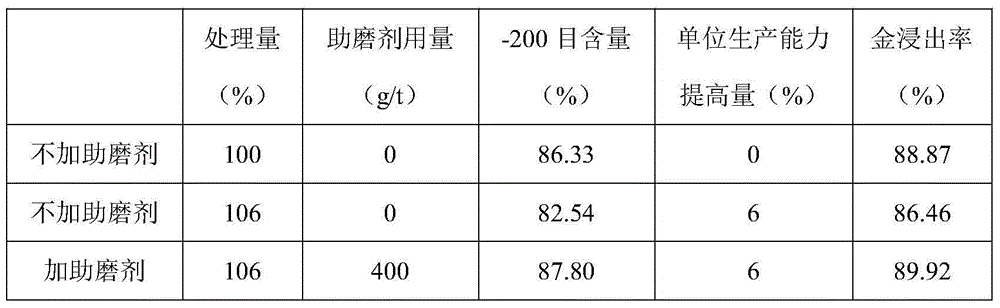

Embodiment 3

[0029] A grinding aid for gold ore grinding with leaching aid function,

[0030] Its components, by weight, include: CaO 2 20%, NaCl 30%, sodium tripolyphosphate 20%, sodium humate 30%, mix the components uniformly in proportion to obtain the grinding aid. Its dosage is 400g / t by weight, and it is directly added in solid form from the feed inlet of the ball mill.

[0031] A quartz vein type gold deposit contains 1.95g / t gold. The metal minerals in this ore are mainly galena and pyrite; the gangue minerals are mainly quartz, potassium feldspar and so on. The hardness of the ore is medium to hard.

[0032] Grinding adopts XMQ67 type 240×200 conical ball mill, steel ball filling rate is 35%, steel ball diameter and weight ratio are 26mm, 10%; 21mm, 15%; 18mm, 65%; 10mm, 10%; total weight 8Kg. The grinding concentration is 70%.

[0033] Cyanide leaching conditions: leaching pulp concentration 40%, cyanide concentration 0.1%, cyanide leaching time 24 hours.

[0034] Applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com