Low-temperature-resisting fireproof polypropylene material easy to shape

A technology of polypropylene material and low temperature resistance. It is applied in the field of polymer composite materials. It can solve the problems of not being able to meet the performance of large-scale boxes, difficulty in forming large-scale boxes, and poor performance of polypropylene, so as to improve post-shrinkage performance and improve mechanical properties. Better performance and optical performance, flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 5

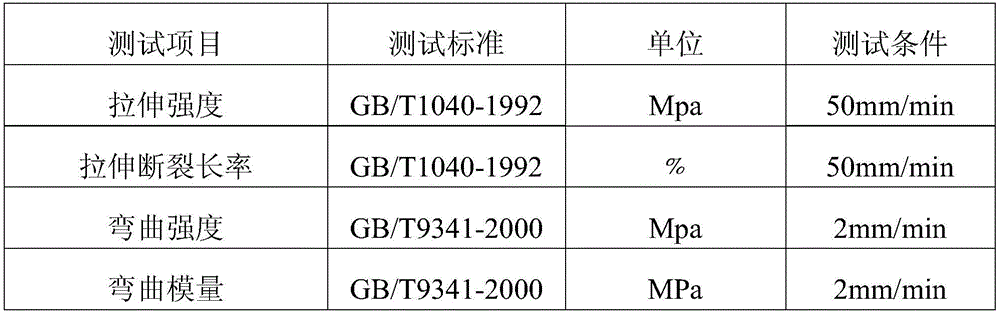

[0024] The easy-to-shape low-temperature-resistant and fire-resistant polypropylene material provided in Embodiment 1 to Embodiment 5 consists of ternary copolymerized polypropylene, random copolymerized polypropylene, halogenated flame retardants, synergistic flame retardants, inorganic fillers, and nucleating agents , each component is calculated by weight ratio, as shown in Table 1:

[0025] Table 1

[0026] component name

Embodiment one

Embodiment two

Embodiment three

Embodiment four

Embodiment five

Terpolymer polypropylene

20

30

35

40

50

random copolymer polypropylene

20

30

35

40

50

Halogen flame retardant

5

10

15

20

30

Synergistic flame retardant

5

10

15

20

30

25

30

35

40

40

Nucleating agent

0.5

1

0.5

1.5

2

[0027] Among them, the terpolymerized polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com